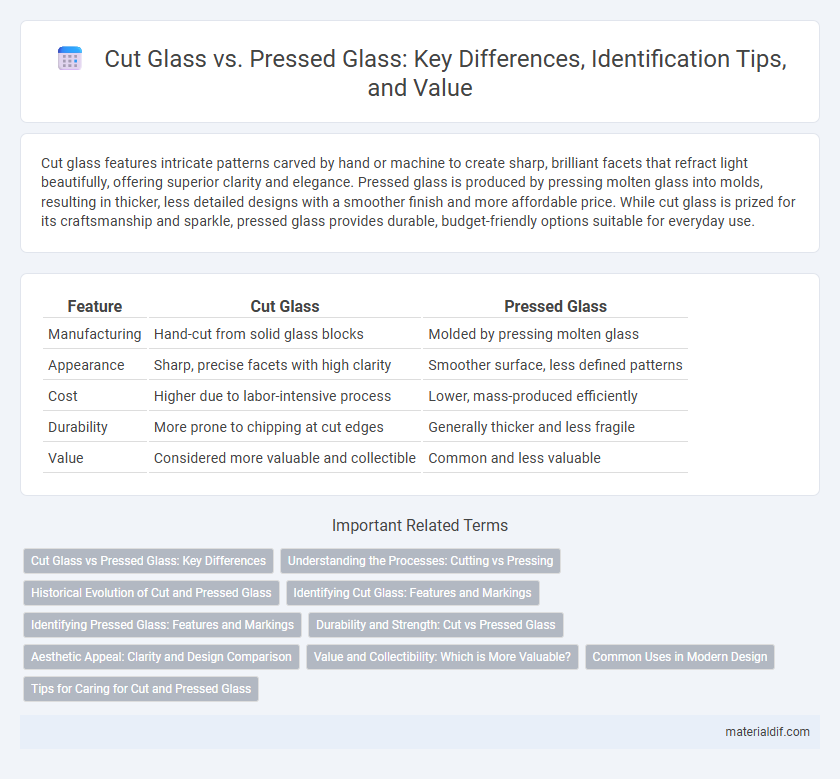

Cut glass features intricate patterns carved by hand or machine to create sharp, brilliant facets that refract light beautifully, offering superior clarity and elegance. Pressed glass is produced by pressing molten glass into molds, resulting in thicker, less detailed designs with a smoother finish and more affordable price. While cut glass is prized for its craftsmanship and sparkle, pressed glass provides durable, budget-friendly options suitable for everyday use.

Table of Comparison

| Feature | Cut Glass | Pressed Glass |

|---|---|---|

| Manufacturing | Hand-cut from solid glass blocks | Molded by pressing molten glass |

| Appearance | Sharp, precise facets with high clarity | Smoother surface, less defined patterns |

| Cost | Higher due to labor-intensive process | Lower, mass-produced efficiently |

| Durability | More prone to chipping at cut edges | Generally thicker and less fragile |

| Value | Considered more valuable and collectible | Common and less valuable |

Cut Glass vs Pressed Glass: Key Differences

Cut glass features intricate designs created by manually cutting into the surface with a rotating wheel, resulting in sharp, precise patterns and high clarity. Pressed glass is formed by pressing molten glass into molds, producing uniform but less detailed designs with a smoother texture and often visible seams. The key differences lie in craftsmanship, pattern complexity, and quality, with cut glass typically valued for its artistry and brilliance compared to the mass-produced nature of pressed glass.

Understanding the Processes: Cutting vs Pressing

Cut glass achieves its distinctive brilliance through a labor-intensive process where artisans meticulously cut patterns into hand-blown glass using rotating wheels, enhancing light refraction and clarity. Pressed glass, formed by pressing molten glass into molds under high pressure, offers more uniform patterns and mass production efficiency but lacks the crisp facets and depth of cut glass. Understanding these processes highlights the superior craftsmanship and detail in cut glass versus the affordability and consistency of pressed glass.

Historical Evolution of Cut and Pressed Glass

Cut glass originated in the late 18th century as artisans crafted intricate designs by hand-cutting polished crystal, showcasing superior clarity and sparkle. Pressed glass emerged in the early 19th century with the advent of mold-pressing technology, allowing mass production of patterned glassware at a lower cost. The historical evolution of these techniques reflects industrial advancements and shifts in consumer demand, with cut glass representing luxury craftsmanship and pressed glass symbolizing accessibility.

Identifying Cut Glass: Features and Markings

Cut glass exhibits sharp, precise facets and intricate patterns achieved by hand or machine cutting, often reflecting light with brilliance and clarity. Distinctive markings include a polished pontil mark on the base or a signature etched by the maker, indicating authenticity. The weight of cut glass is generally heavier compared to pressed glass, which lacks the deep, crisp cuts and has smoother, molded edges.

Identifying Pressed Glass: Features and Markings

Pressed glass is characterized by its uniform thickness, mold seams, and visible patterns created by pressing molten glass into metal molds, distinguishing it from the more intricate designs of cut glass. Key features include less sharp edges, repeated motifs, and often a slightly heavier weight due to the molding process. Markings such as mold numbers, maker's marks, and occasional date stamps typically appear on the base or underside of pressed glass items, aiding in identification and authentication.

Durability and Strength: Cut vs Pressed Glass

Cut glass exhibits superior durability and strength due to its denser structure and the intricate, hand-cut facets that reduce stress points. Pressed glass, created by molding molten glass into shapes, often contains air bubbles and thinner walls, making it more prone to chips and cracks. The manufacturing process of cut glass enhances its resistance to impact, while pressed glass offers affordability at the expense of long-term robustness.

Aesthetic Appeal: Clarity and Design Comparison

Cut glass features intricate, hand-faceted patterns that enhance light refraction, resulting in superior clarity and brilliance compared to pressed glass. Pressed glass, produced through molds, typically exhibits less sharpness and uniformity in design, leading to a more muted sparkle. The aesthetic appeal of cut glass is often favored for its crisp detail and luminous quality, while pressed glass offers affordability and mass-produced consistency.

Value and Collectibility: Which is More Valuable?

Cut glass, characterized by its intricate hand-cut patterns and superior clarity, generally holds higher value and collectibility due to its craftsmanship and rarity compared to pressed glass. Pressed glass, produced by molding molten glass into shapes, is more affordable and commonly found, which reduces its market value among collectors. Collectors often prioritize cut glass pieces for their artistic detail and historical significance, making them more sought-after in auctions and antique markets.

Common Uses in Modern Design

Cut glass is prized for its intricate, hand-faceted patterns, frequently utilized in luxury tableware, chandeliers, and decorative vases that emphasize elegance and craftsmanship. Pressed glass, made by molding molten glass into patterns, is common in mass-produced drinkware, lighting fixtures, and affordable decorative items, offering versatility and cost efficiency in modern interiors. Designers often choose cut glass for statement pieces and pressed glass for functional, everyday use due to their distinct visual appeal and production methods.

Tips for Caring for Cut and Pressed Glass

Cut glass requires gentle handling and cleaning with mild soap and warm water to preserve its intricate patterns, avoiding abrasive materials that can cause scratches. Pressed glass, while more durable, should also be cleaned with non-abrasive cloths and is best dried immediately to prevent water spots and maintain clarity. Storing both types in padded, separated spaces reduces the risk of chipping and preserves their aesthetic quality.

Cut Glass vs Pressed Glass Infographic

materialdif.com

materialdif.com