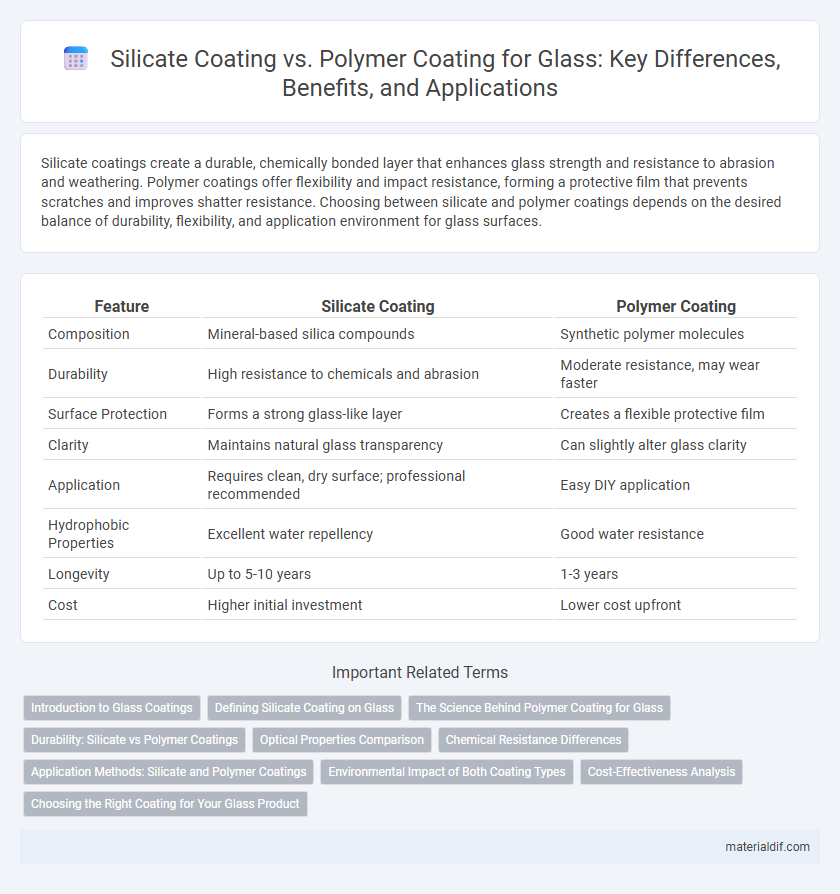

Silicate coatings create a durable, chemically bonded layer that enhances glass strength and resistance to abrasion and weathering. Polymer coatings offer flexibility and impact resistance, forming a protective film that prevents scratches and improves shatter resistance. Choosing between silicate and polymer coatings depends on the desired balance of durability, flexibility, and application environment for glass surfaces.

Table of Comparison

| Feature | Silicate Coating | Polymer Coating |

|---|---|---|

| Composition | Mineral-based silica compounds | Synthetic polymer molecules |

| Durability | High resistance to chemicals and abrasion | Moderate resistance, may wear faster |

| Surface Protection | Forms a strong glass-like layer | Creates a flexible protective film |

| Clarity | Maintains natural glass transparency | Can slightly alter glass clarity |

| Application | Requires clean, dry surface; professional recommended | Easy DIY application |

| Hydrophobic Properties | Excellent water repellency | Good water resistance |

| Longevity | Up to 5-10 years | 1-3 years |

| Cost | Higher initial investment | Lower cost upfront |

Introduction to Glass Coatings

Silicate coatings provide durable, inorganic protection for glass surfaces by forming a chemical bond that enhances scratch resistance and weather durability. Polymer coatings, composed of organic compounds, offer flexible, hydrophobic properties that improve water repellency and reduce dirt adhesion on glass. Both coatings enhance glass performance but differ in chemical composition, durability, and application methods, making them suitable for varied industrial and architectural uses.

Defining Silicate Coating on Glass

Silicate coating on glass consists of a thin, chemically bonded layer of silicate compounds that enhance durability, scratch resistance, and chemical stability. This inorganic coating penetrates the glass surface, forming a robust barrier that improves thermal resistance and protects against environmental degradation. Unlike polymer coatings, silicate coatings maintain clarity and do not yellow over time, making them ideal for long-lasting glass protection.

The Science Behind Polymer Coating for Glass

Polymer coating for glass involves the application of a thin, flexible layer composed of synthetic molecules that form strong covalent bonds with the glass surface, enhancing durability and resistance to scratches and chemicals. Unlike silicate coatings, polymer coatings provide superior hydrophobic properties by creating a nonpolar barrier that repels water and reduces dirt accumulation. The molecular structure of polymer coatings allows for elasticity and self-healing capabilities, extending the lifespan and optical clarity of glass products in industrial and consumer applications.

Durability: Silicate vs Polymer Coatings

Silicate coatings on glass form a durable, inorganic layer that enhances resistance to scratches, chemicals, and weathering by creating a strong bond with the glass surface. Polymer coatings, while flexible and easier to apply, tend to degrade faster under UV exposure and physical abrasion, reducing their long-term protective effectiveness. Silicate coatings generally last significantly longer, providing superior durability for applications requiring extended glass protection.

Optical Properties Comparison

Silicate coatings offer superior optical clarity and higher refractive index, enhancing light transmission and reducing reflection on glass surfaces. Polymer coatings provide flexibility and impact resistance but may exhibit lower transparency and slight color distortion compared to silicate coatings. The choice depends on whether optical performance or mechanical durability is prioritized for the glass application.

Chemical Resistance Differences

Silicate coatings offer superior chemical resistance against acids and alkalis due to their dense, glass-like structure formed from silicon dioxide. Polymer coatings provide flexibility and impact resistance but generally exhibit lower tolerance to strong solvents and aggressive chemicals. Silicate coatings maintain durability and integrity in corrosive environments, making them ideal for industrial applications requiring long-term chemical protection.

Application Methods: Silicate and Polymer Coatings

Silicate coatings on glass are typically applied through brushing, spraying, or dipping, allowing for deep penetration into the glass surface to enhance hardness and chemical resistance. Polymer coatings use methods such as spin coating, spray coating, or dip coating, providing a uniform, flexible layer that improves scratch resistance and hydrophobic properties. Both application techniques are selected based on the desired functional properties and the type of glass substrate being treated.

Environmental Impact of Both Coating Types

Silicate coatings offer a more environmentally sustainable option due to their natural mineral composition and biodegradability, reducing long-term pollution and landfill waste. Polymer coatings, often derived from petrochemicals, may release volatile organic compounds (VOCs) during application and degradation, contributing to air pollution and harmful environmental effects. Selecting silicate coatings can significantly minimize toxic emissions and support eco-friendly glass treatment practices.

Cost-Effectiveness Analysis

Silicate coatings offer superior durability and chemical resistance at a moderate price point, making them cost-effective for long-term glass protection compared to polymer coatings. Polymer coatings typically involve lower initial costs but require more frequent reapplication, increasing overall maintenance expenses. Evaluating total lifecycle costs, silicate coatings provide enhanced value in applications demanding extended wear and minimal upkeep.

Choosing the Right Coating for Your Glass Product

Silicate coatings offer superior hardness and chemical resistance for glass surfaces, enhancing durability in industrial and architectural applications. Polymer coatings provide flexibility and impact resistance, making them ideal for lightweight or curved glass products requiring enhanced safety. Selecting the right coating depends on environmental exposure, mechanical stress, and the desired longevity of the glass product.

Silicate Coating vs Polymer Coating Infographic

materialdif.com

materialdif.com