Fused silica offers superior thermal stability and chemical resistance compared to regular glass, making it ideal for high-precision optical applications. Its low thermal expansion minimizes distortion under temperature fluctuations, whereas regular glass tends to be more prone to cracking and warping. The high purity of fused silica enhances light transmission and durability, outperforming conventional glass in demanding environments.

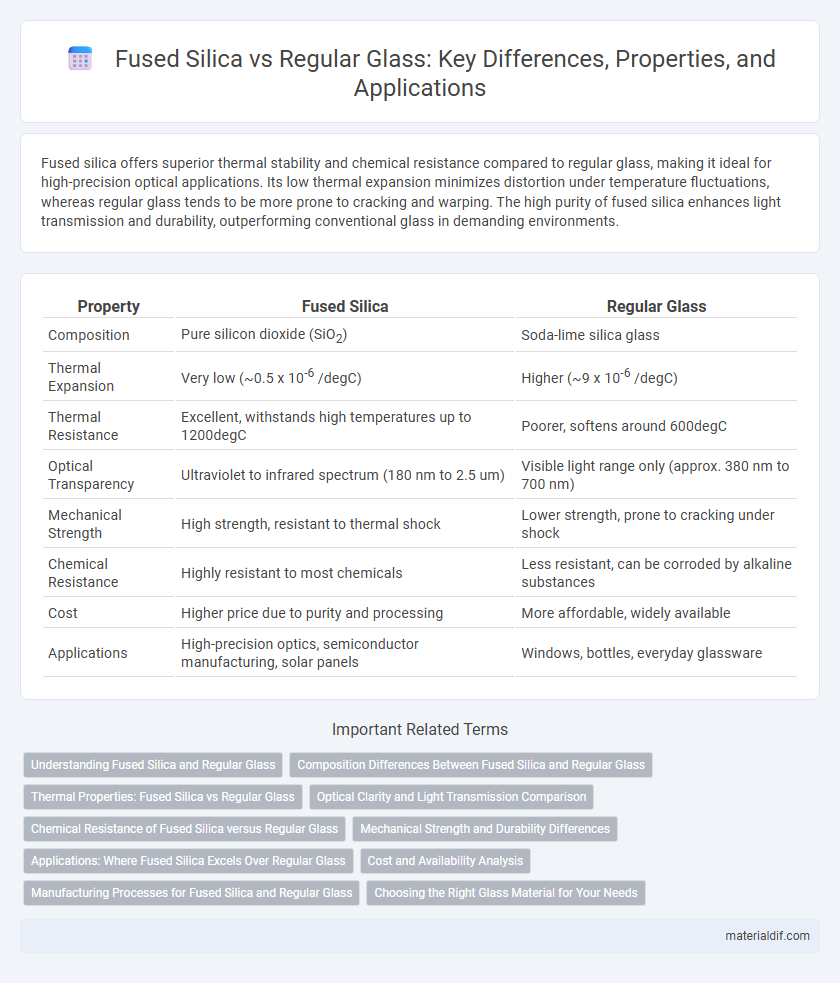

Table of Comparison

| Property | Fused Silica | Regular Glass |

|---|---|---|

| Composition | Pure silicon dioxide (SiO2) | Soda-lime silica glass |

| Thermal Expansion | Very low (~0.5 x 10-6 /degC) | Higher (~9 x 10-6 /degC) |

| Thermal Resistance | Excellent, withstands high temperatures up to 1200degC | Poorer, softens around 600degC |

| Optical Transparency | Ultraviolet to infrared spectrum (180 nm to 2.5 um) | Visible light range only (approx. 380 nm to 700 nm) |

| Mechanical Strength | High strength, resistant to thermal shock | Lower strength, prone to cracking under shock |

| Chemical Resistance | Highly resistant to most chemicals | Less resistant, can be corroded by alkaline substances |

| Cost | Higher price due to purity and processing | More affordable, widely available |

| Applications | High-precision optics, semiconductor manufacturing, solar panels | Windows, bottles, everyday glassware |

Understanding Fused Silica and Regular Glass

Fused silica is a high-purity, amorphous form of silicon dioxide known for its exceptional thermal stability, low thermal expansion, and optical clarity, often used in precision optics and semiconductor manufacturing. Regular glass, typically soda-lime glass, contains impurities and additives that provide durability and affordability but result in higher thermal expansion and lower resistance to thermal shock compared to fused silica. Understanding these differences is crucial for applications requiring high temperature resistance and optical performance, where fused silica outperforms standard glass in durability and transparency.

Composition Differences Between Fused Silica and Regular Glass

Fused silica is composed almost entirely of pure silicon dioxide (SiO2) with a highly uniform and non-crystalline structure, while regular glass typically contains silicon dioxide combined with various metal oxides such as sodium oxide, calcium oxide, and aluminum oxide. This distinct composition in fused silica results in superior optical clarity, higher thermal stability, and a lower coefficient of thermal expansion compared to regular glass. The absence of additional metal oxides in fused silica enhances its resistance to chemical corrosion and ultraviolet radiation, making it ideal for specialized optical and scientific applications.

Thermal Properties: Fused Silica vs Regular Glass

Fused silica exhibits exceptional thermal properties with a low coefficient of thermal expansion around 0.5 x 10^-6 /degC, enabling superior resistance to thermal shock compared to regular glass, which typically has a coefficient near 9 x 10^-6 /degC. Its high melting point of approximately 1710degC and excellent thermal stability make fused silica ideal for high-temperature applications, whereas regular glass softens around 700-900degC. These thermal characteristics of fused silica ensure enhanced durability and performance in environments requiring rapid temperature changes.

Optical Clarity and Light Transmission Comparison

Fused silica offers superior optical clarity compared to regular glass due to its higher purity and uniform molecular structure, resulting in minimal impurities and defects that cause light distortion. It transmits ultraviolet to near-infrared light with a transmission rate exceeding 90%, outperforming regular glass, which typically has lower UV transmission and higher light absorption. This makes fused silica ideal for precision optical applications requiring minimal light scattering and maximum transparency across a broad spectrum.

Chemical Resistance of Fused Silica versus Regular Glass

Fused silica exhibits superior chemical resistance compared to regular glass due to its high purity and silicon dioxide composition, which resists attack from most acids, bases, and solvents. Regular glass, often composed of soda-lime or borosilicate formulations, is more susceptible to chemical corrosion and degradation under harsh environments. This enhanced chemical inertness makes fused silica ideal for applications involving aggressive chemicals or extreme pH conditions.

Mechanical Strength and Durability Differences

Fused silica exhibits superior mechanical strength compared to regular glass due to its low coefficient of thermal expansion and homogeneous amorphous structure, which enhances resistance to thermal shock and mechanical stress. Regular glass, typically composed of soda-lime silica, is more prone to micro-cracking and deformation under mechanical loads, reducing its overall durability. These differences make fused silica ideal for high-stress applications requiring long-term durability and stability.

Applications: Where Fused Silica Excels Over Regular Glass

Fused silica demonstrates superior performance in high-temperature and high-precision optical applications, such as semiconductor manufacturing and fiber optics, due to its exceptional thermal stability and low thermal expansion. It is preferred over regular glass in environments requiring high chemical resistance and UV transparency, like laboratory equipment and aerospace components. Its unique properties enable use in laser optics and ultraviolet lithography where regular glass would fail or degrade quickly.

Cost and Availability Analysis

Fused silica commands a higher price compared to regular glass due to its superior purity, thermal stability, and optical clarity, making it ideal for specialized applications in optics and high-temperature environments. Regular glass remains more cost-effective and widely available, benefiting from mass production and diverse manufacturing processes that support large-scale construction and consumer product use. Availability of fused silica is limited to specific suppliers and niche markets, whereas regular glass enjoys broad accessibility across global markets.

Manufacturing Processes for Fused Silica and Regular Glass

Fused silica is produced through the fusion of high-purity quartz sand at temperatures above 1700degC, resulting in a non-crystalline, amorphous structure with exceptional thermal and optical properties. Regular glass, typically soda-lime glass, is manufactured by melting a mixture of silica sand, soda ash, and limestone at around 1500degC, forming a crystalline or semi-crystalline structure with lower purity and reduced thermal stability compared to fused silica. The manufacturing process of fused silica demands higher energy consumption and specialized equipment, reflecting its use in high-performance applications like semiconductor wafers and optical components.

Choosing the Right Glass Material for Your Needs

Fused silica offers superior thermal stability, high optical transparency, and excellent chemical resistance compared to regular glass, making it ideal for high-precision applications like laboratory equipment and semiconductor manufacturing. Regular glass, also known as soda-lime glass, is more cost-effective and mechanically robust, suitable for everyday uses such as windows, bottles, and household items. Selecting the right glass material depends on factors like temperature tolerance, optical clarity, chemical exposure, and budget constraints to ensure optimal performance and durability.

Fused Silica vs Regular Glass Infographic

materialdif.com

materialdif.com