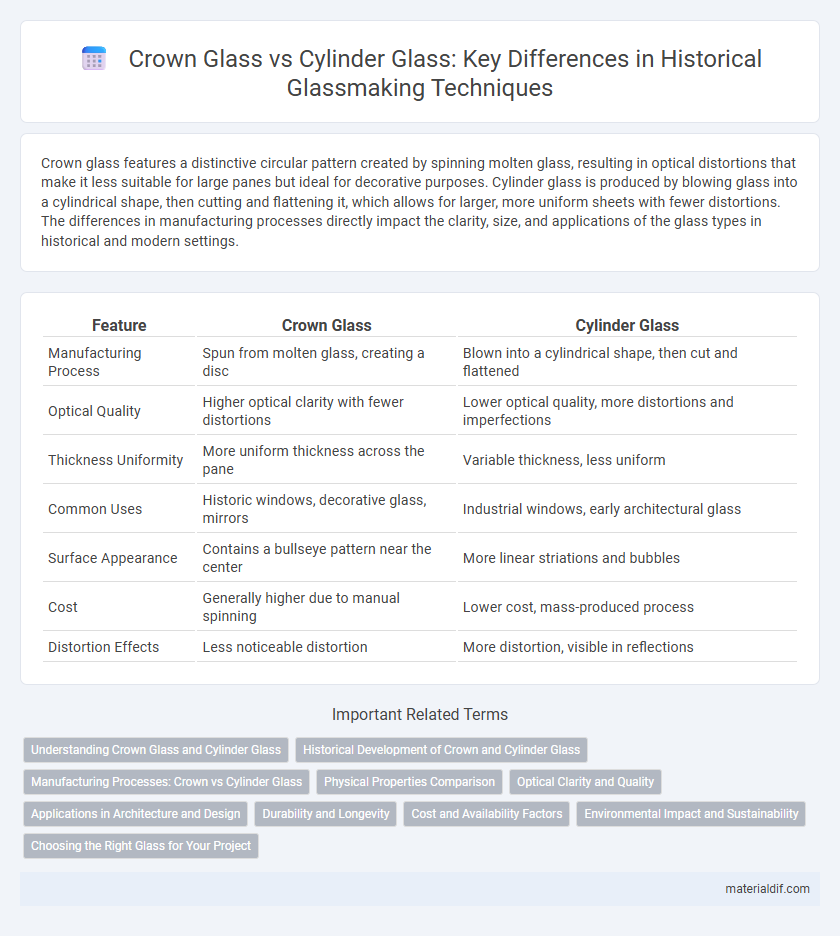

Crown glass features a distinctive circular pattern created by spinning molten glass, resulting in optical distortions that make it less suitable for large panes but ideal for decorative purposes. Cylinder glass is produced by blowing glass into a cylindrical shape, then cutting and flattening it, which allows for larger, more uniform sheets with fewer distortions. The differences in manufacturing processes directly impact the clarity, size, and applications of the glass types in historical and modern settings.

Table of Comparison

| Feature | Crown Glass | Cylinder Glass |

|---|---|---|

| Manufacturing Process | Spun from molten glass, creating a disc | Blown into a cylindrical shape, then cut and flattened |

| Optical Quality | Higher optical clarity with fewer distortions | Lower optical quality, more distortions and imperfections |

| Thickness Uniformity | More uniform thickness across the pane | Variable thickness, less uniform |

| Common Uses | Historic windows, decorative glass, mirrors | Industrial windows, early architectural glass |

| Surface Appearance | Contains a bullseye pattern near the center | More linear striations and bubbles |

| Cost | Generally higher due to manual spinning | Lower cost, mass-produced process |

| Distortion Effects | Less noticeable distortion | More distortion, visible in reflections |

Understanding Crown Glass and Cylinder Glass

Crown glass is produced by spinning molten glass into a disk, creating a characteristic bulge called a "bullseye," which results in varying thickness and optical distortions. Cylinder glass is made by blowing a glass cylinder, cutting it lengthwise, and flattening it into sheets, producing more uniform thickness and fewer imperfections. Both methods influence the clarity and durability of window glass, with cylinder glass generally preferred for its even surface and reduced distortion.

Historical Development of Crown and Cylinder Glass

Crown glass originated in the medieval period, characterized by its method of spinning molten glass into a large disc, producing a distinctive bullseye pattern and uneven thickness. Cylinder glass emerged during the 19th century Industrial Revolution, where glassmakers blew large cylinders, cut them longitudinally, and flattened them for more uniform panes. The transition from crown to cylinder glass marked a significant advancement in glass manufacturing, enabling larger, clearer windows for architectural use.

Manufacturing Processes: Crown vs Cylinder Glass

Crown glass manufacturing involves blowing molten glass into a hollow globe, then spinning it rapidly to create a flat disk with varying thickness, ideal for antique windowpanes. Cylinder glass production entails blowing a large glass bubble, cutting it lengthwise, and then reheating and flattening it into sheets, enabling more uniform thickness and fewer distortions. These distinct processes affect the optical quality, durability, and production efficiency of the resulting glass types.

Physical Properties Comparison

Crown glass exhibits higher optical clarity and lower dispersion compared to cylinder glass, making it ideal for precision lenses. Cylinder glass tends to have more uniform thickness and better mechanical strength, enhancing its durability in architectural applications. The difference in physical properties stems from their manufacturing processes, with crown glass being spun and cylinder glass blown and flattened.

Optical Clarity and Quality

Crown glass offers superior optical clarity due to its uniform composition and fewer impurities, resulting in minimal distortion and high light transmission. Cylinder glass, produced by flattening blown glass tubes, often contains more surface imperfections and optical aberrations, reducing its overall clarity. The consistent quality of crown glass makes it preferable for precision optical applications and high-quality glazing.

Applications in Architecture and Design

Crown glass, known for its characteristic swirl patterns and optical distortions, is often used in heritage restoration and decorative windows to impart a vintage aesthetic. Cylinder glass offers larger, uniform panes with improved clarity, making it ideal for modern architectural applications such as storefronts, curtain walls, and skylights. Both types contribute distinct visual qualities, influencing design choices based on light transmission, texture, and historical authenticity.

Durability and Longevity

Crown glass exhibits high resistance to impact due to its circular pattern stress distribution, enhancing durability in historic window applications. Cylinder glass offers superior uniformity and fewer distortions, contributing to longer lifespan under consistent environmental exposure. Both types demonstrate resilience, but cylinder glass generally provides greater longevity in modern architectural use.

Cost and Availability Factors

Crown glass tends to be more expensive and less readily available due to its complex manufacturing process involving spinning molten glass into discs, which limits production scale. Cylinder glass, produced by blowing and rolling molten glass into large sheets, is generally more cost-effective and widely accessible for commercial use. The cost efficiency and higher availability of cylinder glass make it a preferred choice in large-scale architectural and automotive applications.

Environmental Impact and Sustainability

Crown glass production generates fewer emissions and consumes less energy compared to cylinder glass due to its simpler manufacturing process, making it more environmentally sustainable. Cylinder glass often requires additional processing steps such as grinding and polishing, leading to higher energy usage and increased carbon footprint. Sustainable glass manufacturing increasingly favors crown glass for its lower environmental impact and resource efficiency.

Choosing the Right Glass for Your Project

Selecting between crown glass and cylinder glass depends on your project's clarity and distortion requirements. Crown glass offers superior optical quality with minimal distortion, making it ideal for decorative windows and historical restorations. Cylinder glass, produced by blowing molten glass into a cylinder and flattening it, provides versatility and can be more cost-effective for large-scale commercial projects.

Crown glass vs Cylinder glass Infographic

materialdif.com

materialdif.com