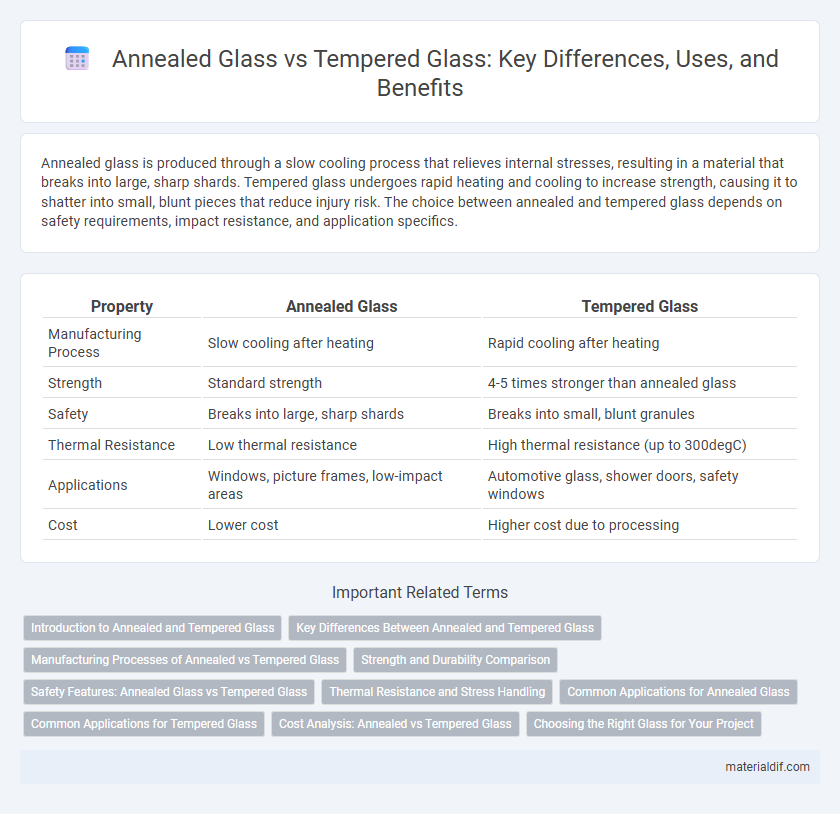

Annealed glass is produced through a slow cooling process that relieves internal stresses, resulting in a material that breaks into large, sharp shards. Tempered glass undergoes rapid heating and cooling to increase strength, causing it to shatter into small, blunt pieces that reduce injury risk. The choice between annealed and tempered glass depends on safety requirements, impact resistance, and application specifics.

Table of Comparison

| Property | Annealed Glass | Tempered Glass |

|---|---|---|

| Manufacturing Process | Slow cooling after heating | Rapid cooling after heating |

| Strength | Standard strength | 4-5 times stronger than annealed glass |

| Safety | Breaks into large, sharp shards | Breaks into small, blunt granules |

| Thermal Resistance | Low thermal resistance | High thermal resistance (up to 300degC) |

| Applications | Windows, picture frames, low-impact areas | Automotive glass, shower doors, safety windows |

| Cost | Lower cost | Higher cost due to processing |

Introduction to Annealed and Tempered Glass

Annealed glass undergoes a slow cooling process after being formed, resulting in a smooth, flat surface with excellent clarity but lower strength and safety characteristics. Tempered glass is heat-treated through rapid cooling, enhancing its strength up to four times that of annealed glass and causing it to break into small, less harmful granules instead of sharp shards. These fundamental differences make annealed glass suitable for applications prioritizing visual quality, while tempered glass is favored for safety and impact resistance in architectural and automotive uses.

Key Differences Between Annealed and Tempered Glass

Annealed glass is cooled slowly to remove internal stresses, making it easier to cut and shape but more prone to breakage, while tempered glass undergoes rapid cooling to increase strength and safety by shattering into small, blunt pieces when broken. Tempered glass offers approximately four to five times the strength of annealed glass, making it ideal for applications requiring higher impact resistance, such as automotive windows and building facades. Annealed glass is commonly used in situations where mechanical processing is needed after production, whereas tempered glass cannot be modified post-tempering without losing its strength characteristics.

Manufacturing Processes of Annealed vs Tempered Glass

Annealed glass undergoes a slow cooling process after being heated to relieve internal stresses, resulting in a more flexible but less strong structure. Tempered glass is rapidly cooled or "quenched" after heating, creating high compressive stresses on the surface that significantly increase its strength and resistance to impact. The controlled cooling techniques differentiate the internal stress profiles and safety characteristics of annealed and tempered glass.

Strength and Durability Comparison

Annealed glass, produced through slow cooling, offers standard strength but is more prone to breakage under impact or thermal stress compared to tempered glass. Tempered glass undergoes rapid cooling during manufacturing, resulting in increased strength--typically four to five times greater than annealed glass--and enhanced durability against impacts and temperature fluctuations. This makes tempered glass ideal for safety-critical applications such as automotive windows, shower enclosures, and architectural facades where structural integrity is paramount.

Safety Features: Annealed Glass vs Tempered Glass

Tempered glass offers superior safety features compared to annealed glass due to its enhanced strength and controlled shattering pattern, breaking into small, blunt pieces that reduce injury risk. Annealed glass, being standard untreated glass, breaks into large, sharp shards that pose significant hazards. Safety standards in construction and automotive industries favor tempered glass for its impact resistance and safer fracture behavior.

Thermal Resistance and Stress Handling

Annealed glass exhibits lower thermal resistance and is prone to breakage under rapid temperature changes due to its unstrengthened structure. Tempered glass undergoes controlled thermal treatment, which significantly enhances its stress handling capacity and thermal resistance, allowing it to withstand higher temperatures and sudden thermal shocks without fracturing. This makes tempered glass ideal for applications requiring durability and safety under thermal stress conditions.

Common Applications for Annealed Glass

Annealed glass is commonly used in applications such as picture frames, windows, and glass doors where strength is not a primary requirement. It provides clarity and ease of cutting or shaping, making it ideal for decorative and interior uses. This type of glass is preferred in situations where the glass is not exposed to high impact or thermal stress.

Common Applications for Tempered Glass

Tempered glass is widely used in automotive windows, building facades, and shower doors due to its enhanced strength and safety properties compared to annealed glass. It is also prevalent in glass tables, doors, and protective screens, providing resistance to impact and thermal stress. Its ability to crumble into small, blunt pieces reduces injury risk, making it ideal for safety-critical applications.

Cost Analysis: Annealed vs Tempered Glass

Annealed glass generally costs less than tempered glass due to simpler manufacturing processes and lower energy requirements. Tempered glass involves controlled thermal treatments that increase production expenses but offer enhanced safety and strength benefits. For projects prioritizing budget, annealed glass presents a cost-effective option, while tempered glass justifies its higher price with durability and compliance with building codes.

Choosing the Right Glass for Your Project

Annealed glass offers superior clarity and is ideal for applications where shaping and cutting are essential, but it lacks the strength and safety features of tempered glass. Tempered glass undergoes a heat treatment process that enhances its strength up to four times and causes it to shatter into small, blunt pieces upon breaking, making it suitable for high-impact and safety-sensitive environments. Selecting the right glass depends on balancing aesthetic needs, structural requirements, and safety regulations specific to your project.

Annealed glass vs Tempered glass Infographic

materialdif.com

materialdif.com