Float glass offers superior flatness and uniform thickness due to its production process, where molten glass floats on a bed of molten metal, typically tin. Cast glass, created by pouring molten glass into molds, results in thicker, more textured surfaces ideal for artistic and decorative applications. Choosing between float and cast glass depends on the need for clarity and smoothness versus design complexity and dimensional depth.

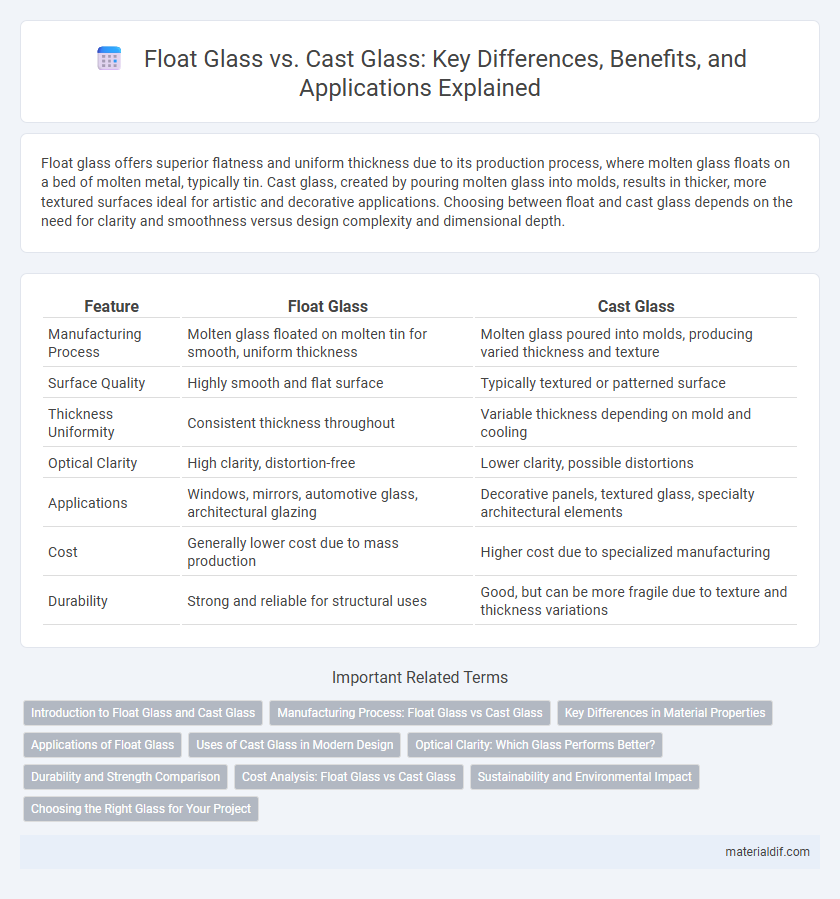

Table of Comparison

| Feature | Float Glass | Cast Glass |

|---|---|---|

| Manufacturing Process | Molten glass floated on molten tin for smooth, uniform thickness | Molten glass poured into molds, producing varied thickness and texture |

| Surface Quality | Highly smooth and flat surface | Typically textured or patterned surface |

| Thickness Uniformity | Consistent thickness throughout | Variable thickness depending on mold and cooling |

| Optical Clarity | High clarity, distortion-free | Lower clarity, possible distortions |

| Applications | Windows, mirrors, automotive glass, architectural glazing | Decorative panels, textured glass, specialty architectural elements |

| Cost | Generally lower cost due to mass production | Higher cost due to specialized manufacturing |

| Durability | Strong and reliable for structural uses | Good, but can be more fragile due to texture and thickness variations |

Introduction to Float Glass and Cast Glass

Float glass is produced by floating molten glass on a bed of molten metal, typically tin, resulting in a smooth, uniform thickness with excellent optical clarity. Cast glass is created by pouring molten glass into molds, allowing for thicker, textured, or sculpted forms with artistic or architectural applications. The float process dominates in manufacturing flat glass for windows and mirrors, while cast glass is preferred for decorative and specialized uses.

Manufacturing Process: Float Glass vs Cast Glass

Float glass is manufactured by floating molten glass on a bed of molten tin, creating a smooth, uniform thickness ideal for windows and mirrors. Cast glass involves pouring molten glass into molds where it cools and solidifies, allowing for textured or three-dimensional artistic shapes. The float process is highly automated for large-scale production, while cast glass offers more customization but requires longer cooling times to prevent stress.

Key Differences in Material Properties

Float glass is produced by floating molten glass on a bed of molten metal, resulting in a smooth, uniform thickness with excellent optical clarity and minimal distortion. Cast glass is made by pouring molten glass into molds, allowing for varied thickness and textured surfaces, which often leads to less optical clarity but greater design versatility. The key material property difference lies in float glass's high uniformity and flatness versus cast glass's customizable shapes and textures.

Applications of Float Glass

Float glass is widely used in architectural applications due to its uniform thickness, smooth surface, and excellent optical clarity, making it ideal for windows, facades, and interior partitions. Its versatility extends to automotive glazing, where it provides safety and durability while allowing for complex curved shapes. Unlike cast glass, float glass can be easily tempered, laminated, and coated to enhance strength, thermal insulation, and energy efficiency in building construction.

Uses of Cast Glass in Modern Design

Cast glass in modern design serves primarily as a versatile material for creating intricate architectural features such as textured walls, decorative panels, and sculptural elements that emphasize depth and light play. Unlike float glass, which is valued for its uniformity and clarity in windows and facades, cast glass allows for customization in thickness, texture, and embedded patterns, making it ideal for artistic installations and bespoke interior surfaces. Its ability to diffuse light softly enhances ambiance while offering structural strength in both residential and commercial projects.

Optical Clarity: Which Glass Performs Better?

Float glass exhibits superior optical clarity compared to cast glass due to its uniform thickness and smooth, flat surface achieved through the float process, which minimizes distortions and imperfections. Cast glass often contains minor bubbles and surface irregularities from the molding process, resulting in less transparency and clarity. For applications requiring high optical performance, such as windows or display screens, float glass is the preferred choice due to its consistent clarity and visual quality.

Durability and Strength Comparison

Float glass, manufactured by floating molten glass on a bed of molten metal, offers uniform thickness and smooth surfaces, resulting in high tensile strength and excellent durability for architectural applications. Cast glass, produced by pouring molten glass into molds, typically exhibits greater thickness variation and can contain internal stresses, leading to lower mechanical strength compared to float glass. In terms of impact resistance and long-term structural performance, float glass surpasses cast glass due to its consistent composition and fewer defects.

Cost Analysis: Float Glass vs Cast Glass

Float glass production typically incurs lower costs due to its continuous manufacturing process and high efficiency, making it more affordable for large-scale projects. Cast glass involves higher expenses stemming from its labor-intensive pouring and annealing stages, which increase material wastage and production time. Budget considerations often favor float glass for cost-sensitive applications, while cast glass is reserved for specialized uses requiring unique optical or textural properties.

Sustainability and Environmental Impact

Float glass production utilizes a continuous process with molten glass floated on a bed of molten tin, resulting in higher energy efficiency and lower emissions compared to cast glass, which requires slower cooling and more energy-intensive methods. Float glass is more recyclable and generates less waste due to its uniform thickness and fewer defects, enhancing its sustainability profile over cast glass. Cast glass often involves molds and batch processing that increase material waste and carbon footprint, making float glass the preferred choice for environmentally conscious applications.

Choosing the Right Glass for Your Project

Float glass offers superior clarity and uniform thickness, making it ideal for windows, mirrors, and large-scale architectural applications. Cast glass, with its textured surface and varied thickness, provides unique aesthetic effects preferred in decorative or artistic installations. Selecting the right glass depends on your project's needs for optical quality versus design texture and structural requirements.

Float glass vs Cast glass Infographic

materialdif.com

materialdif.com