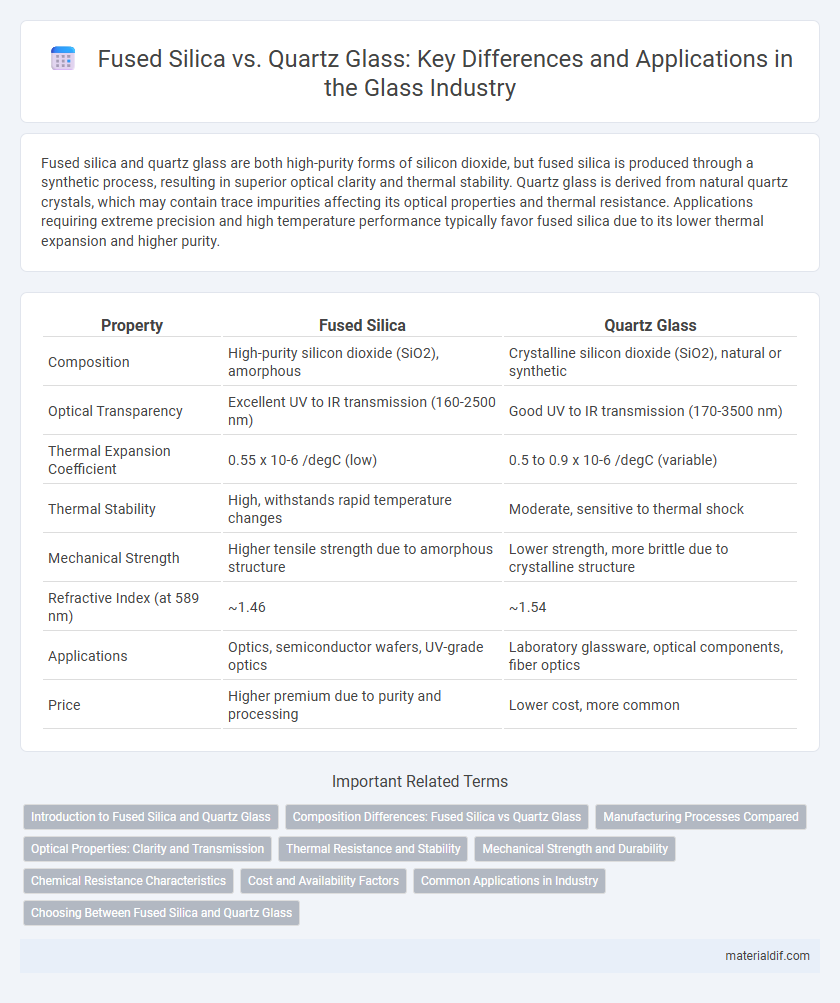

Fused silica and quartz glass are both high-purity forms of silicon dioxide, but fused silica is produced through a synthetic process, resulting in superior optical clarity and thermal stability. Quartz glass is derived from natural quartz crystals, which may contain trace impurities affecting its optical properties and thermal resistance. Applications requiring extreme precision and high temperature performance typically favor fused silica due to its lower thermal expansion and higher purity.

Table of Comparison

| Property | Fused Silica | Quartz Glass |

|---|---|---|

| Composition | High-purity silicon dioxide (SiO2), amorphous | Crystalline silicon dioxide (SiO2), natural or synthetic |

| Optical Transparency | Excellent UV to IR transmission (160-2500 nm) | Good UV to IR transmission (170-3500 nm) |

| Thermal Expansion Coefficient | 0.55 x 10-6 /degC (low) | 0.5 to 0.9 x 10-6 /degC (variable) |

| Thermal Stability | High, withstands rapid temperature changes | Moderate, sensitive to thermal shock |

| Mechanical Strength | Higher tensile strength due to amorphous structure | Lower strength, more brittle due to crystalline structure |

| Refractive Index (at 589 nm) | ~1.46 | ~1.54 |

| Applications | Optics, semiconductor wafers, UV-grade optics | Laboratory glassware, optical components, fiber optics |

| Price | Higher premium due to purity and processing | Lower cost, more common |

Introduction to Fused Silica and Quartz Glass

Fused silica, a high-purity glass made from silicon dioxide, offers exceptional thermal stability, low thermal expansion, and excellent optical transparency in ultraviolet to infrared wavelengths. Quartz glass, derived from naturally occurring quartz crystals, features similar optical properties but often contains more impurities, affecting its mechanical strength and thermal shock resistance. Both materials are widely used in high-precision optics, semiconductor manufacturing, and scientific instrumentation due to their superior chemical durability and optical clarity.

Composition Differences: Fused Silica vs Quartz Glass

Fused silica consists almost entirely of silicon dioxide (SiO2) in a non-crystalline, amorphous form, whereas quartz glass is made from crystalline silicon dioxide derived directly from natural quartz. The manufacturing process of fused silica involves melting high-purity silica powder, resulting in fewer impurities and enhanced thermal stability compared to quartz glass. Quartz glass retains microscopic crystalline structures, leading to different optical and mechanical properties than the uniform molecular structure of fused silica.

Manufacturing Processes Compared

Fused silica is manufactured by melting high-purity silicon dioxide at temperatures above 2000degC using electric fusion, resulting in a non-crystalline, amorphous glass with exceptional thermal stability and low thermal expansion. Quartz glass, derived from crystalline quartz, undergoes flame fusion or hydrothermal synthesis processes, preserving its crystalline structure but introducing higher impurity levels that affect optical clarity. The manufacturing method of fused silica offers superior homogeneity and purity compared to quartz glass, making it ideal for high-precision optical and semiconductor applications.

Optical Properties: Clarity and Transmission

Fused silica offers superior optical clarity with a high transmission rate of up to 99.9% across a broad spectrum, including ultraviolet wavelengths, making it ideal for precision optics. Quartz glass also provides excellent transparency but typically exhibits slightly lower UV transmission and higher birefringence compared to fused silica. The minimal inclusions and uniform structure of fused silica result in enhanced clarity and reduced light scattering, outperforming standard quartz glass in demanding optical applications.

Thermal Resistance and Stability

Fused silica exhibits superior thermal resistance with a melting point around 1713degC, significantly higher than standard quartz glass, enhancing its performance in high-temperature applications. Its low thermal expansion coefficient (~0.5 x 10^-6 /degC) ensures exceptional thermal stability, reducing stress and deformation under rapid temperature changes compared to quartz glass, which has a higher expansion rate. These properties make fused silica ideal for precision optics, semiconductor manufacturing, and environments demanding consistent dimensional stability under thermal stress.

Mechanical Strength and Durability

Fused silica exhibits superior mechanical strength and enhanced durability compared to quartz glass due to its amorphous structure, which lacks internal grain boundaries that can act as points of weakness. Quartz glass, being crystalline, is more prone to microfractures under mechanical stress and thermal cycling, leading to reduced lifespan in demanding applications. The exceptional resistance of fused silica to mechanical deformation and thermal shock makes it ideal for high-precision optical and industrial uses requiring long-term reliability.

Chemical Resistance Characteristics

Fused silica exhibits superior chemical resistance compared to quartz glass due to its high purity and amorphous structure, minimizing susceptibility to corrosion by acids and alkalis. Quartz glass, composed of crystalline silicon dioxide, is more prone to hydrofluoric acid attack and can develop surface deterioration under aggressive chemical exposure. The inert nature of fused silica makes it ideal for applications requiring stable performance in highly corrosive environments.

Cost and Availability Factors

Fused silica offers superior purity and thermal stability but comes at a higher cost due to its specialized manufacturing process, limiting its availability compared to quartz glass. Quartz glass, derived from natural quartz crystals, is more readily available and generally less expensive, making it a preferred choice for cost-sensitive applications. The cost disparity between fused silica and quartz glass significantly influences material selection in industries requiring high-performance optical components.

Common Applications in Industry

Fused silica and quartz glass are widely used in industries requiring high thermal stability and optical clarity, such as semiconductor manufacturing, aerospace, and telecommunications. Fused silica offers superior purity and low thermal expansion, making it ideal for precision lenses, optical fibers, and high-temperature crucibles. Quartz glass is favored in applications like laboratory equipment and UV optics due to its durability and resistance to harsh chemical environments.

Choosing Between Fused Silica and Quartz Glass

Fused silica and quartz glass both offer excellent thermal stability and optical clarity but differ in purity and manufacturing processes; fused silica is a synthetic, high-purity form of silicon dioxide with superior ultraviolet transmission and lower thermal expansion. Quartz glass, typically made from natural quartz crystals, provides good mechanical strength and is cost-effective for general applications requiring durability. Selecting between the two depends on specific needs such as optical performance, thermal resistance, and budget constraints, with fused silica being preferred for high-precision optics and quartz glass suitable for robust industrial uses.

Fused silica vs Quartz glass Infographic

materialdif.com

materialdif.com