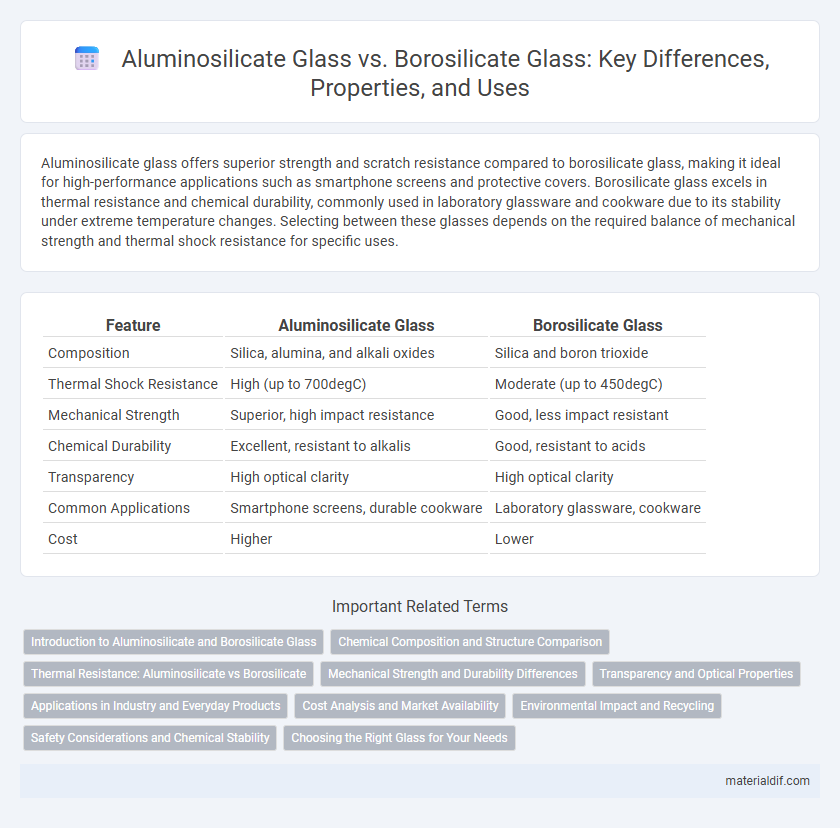

Aluminosilicate glass offers superior strength and scratch resistance compared to borosilicate glass, making it ideal for high-performance applications such as smartphone screens and protective covers. Borosilicate glass excels in thermal resistance and chemical durability, commonly used in laboratory glassware and cookware due to its stability under extreme temperature changes. Selecting between these glasses depends on the required balance of mechanical strength and thermal shock resistance for specific uses.

Table of Comparison

| Feature | Aluminosilicate Glass | Borosilicate Glass |

|---|---|---|

| Composition | Silica, alumina, and alkali oxides | Silica and boron trioxide |

| Thermal Shock Resistance | High (up to 700degC) | Moderate (up to 450degC) |

| Mechanical Strength | Superior, high impact resistance | Good, less impact resistant |

| Chemical Durability | Excellent, resistant to alkalis | Good, resistant to acids |

| Transparency | High optical clarity | High optical clarity |

| Common Applications | Smartphone screens, durable cookware | Laboratory glassware, cookware |

| Cost | Higher | Lower |

Introduction to Aluminosilicate and Borosilicate Glass

Aluminosilicate glass contains alumina (Al2O3) as a primary additive, enhancing its thermal and mechanical strength, making it ideal for smartphone screens and aerospace applications. Borosilicate glass incorporates boron trioxide (B2O3), offering excellent thermal resistance and chemical durability, widely used in laboratory glassware and cookware. Both types provide distinct benefits in heat resistance and durability, with aluminosilicate excelling in impact resistance and borosilicate favored for its thermal shock resistance.

Chemical Composition and Structure Comparison

Aluminosilicate glass features a chemical composition rich in aluminum oxide (Al2O3) and silica (SiO2), providing a robust three-dimensional network structure that enhances thermal stability and mechanical strength. Borosilicate glass, characterized by a significant amount of boron oxide (B2O3) alongside silica, forms a more flexible network with fewer cross-links, resulting in superior thermal shock resistance. The presence of aluminum in aluminosilicate glass increases durability and resistance to chemical corrosion compared to the boron-rich structure of borosilicate glass, which excels in high-temperature applications due to its lower coefficient of thermal expansion.

Thermal Resistance: Aluminosilicate vs Borosilicate

Aluminosilicate glass exhibits superior thermal resistance compared to borosilicate glass, with a higher softening point typically around 1,120degC versus borosilicate's 820degC. This enhanced thermal stability makes aluminosilicate glass ideal for applications involving rapid temperature changes and high thermal shock resistance. Borosilicate glass still offers good thermal resistance but is more suited for moderate heat exposure and laboratory glassware.

Mechanical Strength and Durability Differences

Aluminosilicate glass exhibits higher mechanical strength and improved impact resistance compared to borosilicate glass due to its denser atomic structure and enhanced chemical bonding. Borosilicate glass offers superior thermal durability with excellent resistance to thermal shock but has lower tensile strength than aluminosilicate variants. The choice between these glasses depends on the application's need for either enhanced mechanical robustness or exceptional thermal stability.

Transparency and Optical Properties

Aluminosilicate glass offers higher durability and excellent resistance to thermal shock compared to borosilicate glass, while maintaining superior transparency with minimal light distortion. Borosilicate glass is prized for its low thermal expansion and chemical stability, but it has slightly lower optical clarity due to its refractive index properties. Both glass types exhibit strong optical transparency, but aluminosilicate glass is preferred in applications demanding enhanced scratch resistance and consistent light transmission.

Applications in Industry and Everyday Products

Aluminosilicate glass is widely used in smartphone screens and protective eyewear due to its high scratch resistance and thermal durability, making it ideal for electronics and safety equipment. Borosilicate glass, known for its excellent chemical resistance and thermal shock tolerance, is commonly applied in laboratory glassware, cookware, and lighting, where stability under temperature fluctuations is crucial. Both types of glass serve distinct industrial and everyday applications, with aluminosilicate favored for toughness and borosilicate preferred for heat and chemical resistance.

Cost Analysis and Market Availability

Aluminosilicate glass generally incurs higher production costs due to its complex manufacturing process and specialized raw materials, making it less price-competitive compared to borosilicate glass. Borosilicate glass offers greater market availability driven by its widespread use in laboratory equipment, cookware, and consumer glassware, resulting in economies of scale that lower its cost. Market trends indicate growing demand for aluminosilicate glass in high-performance applications, but borosilicate glass continues to dominate mass-market segments due to affordability and established supply chains.

Environmental Impact and Recycling

Aluminosilicate glass features a high resistance to thermal shock and chemical corrosion, making it more durable and reducing the frequency of replacements compared to borosilicate glass. Borosilicate glass, while also resilient, contains boron oxide which complicates recycling processes and can lead to higher energy consumption during remelting. Aluminosilicate glass can be recycled more efficiently within standard glass recycling streams, minimizing environmental impact through reduced landfill waste and lower carbon emissions.

Safety Considerations and Chemical Stability

Aluminosilicate glass offers superior chemical stability and higher resistance to thermal shock compared to borosilicate glass, making it ideal for safety-critical applications in laboratory and industrial environments. Borosilicate glass, while also chemically stable, is more prone to stress-induced fractures under rapid temperature changes, potentially compromising safety in high-heat scenarios. The enhanced durability of aluminosilicate glass reduces contamination risk and improves long-term performance in aggressive chemical exposures.

Choosing the Right Glass for Your Needs

Aluminosilicate glass offers superior chemical durability and higher mechanical strength, making it ideal for electronic displays and protective covers requiring scratch resistance and thermal stability. Borosilicate glass excels in thermal shock resistance and is commonly used in laboratory equipment and cookware where rapid temperature changes occur. Selecting the right glass depends on the application's priority for mechanical strength versus thermal resilience.

Aluminosilicate glass vs Borosilicate glass Infographic

materialdif.com

materialdif.com