Fused quartz offers superior thermal stability and higher resistance to thermal shock compared to standard glass, making it ideal for high-temperature applications. Its exceptional clarity and low thermal expansion result in better optical performance and durability under extreme conditions. Standard glass, while more affordable and easier to manufacture, lacks the enhanced strength and heat resistance of fused quartz.

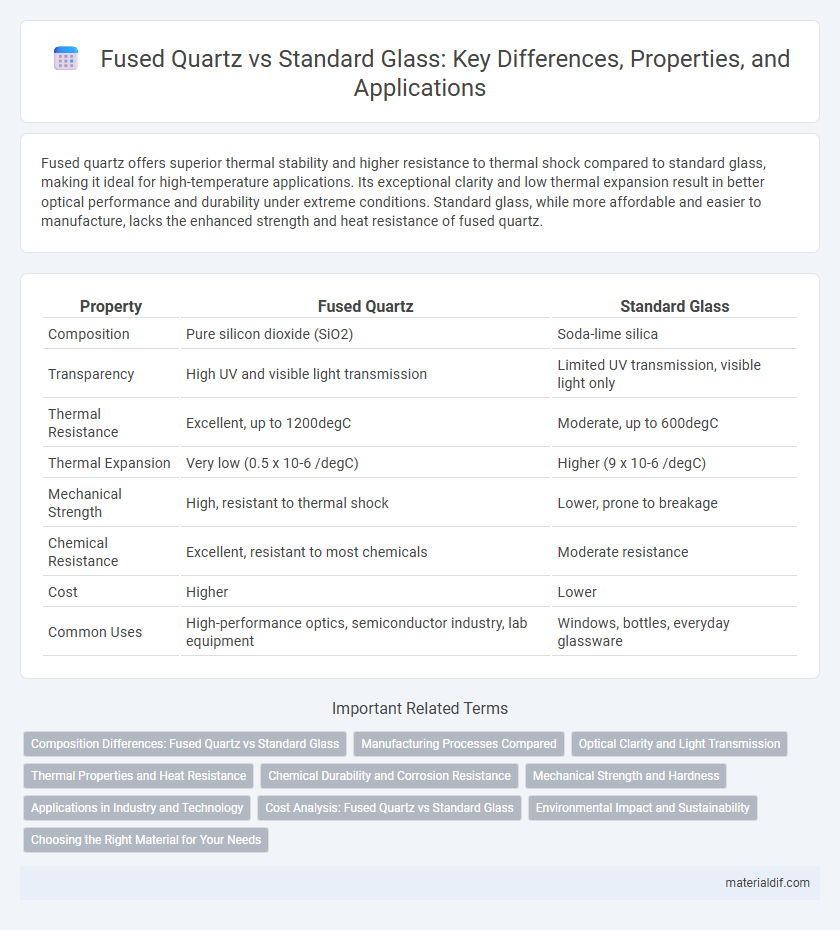

Table of Comparison

| Property | Fused Quartz | Standard Glass |

|---|---|---|

| Composition | Pure silicon dioxide (SiO2) | Soda-lime silica |

| Transparency | High UV and visible light transmission | Limited UV transmission, visible light only |

| Thermal Resistance | Excellent, up to 1200degC | Moderate, up to 600degC |

| Thermal Expansion | Very low (0.5 x 10-6 /degC) | Higher (9 x 10-6 /degC) |

| Mechanical Strength | High, resistant to thermal shock | Lower, prone to breakage |

| Chemical Resistance | Excellent, resistant to most chemicals | Moderate resistance |

| Cost | Higher | Lower |

| Common Uses | High-performance optics, semiconductor industry, lab equipment | Windows, bottles, everyday glassware |

Composition Differences: Fused Quartz vs Standard Glass

Fused quartz consists almost entirely of pure silicon dioxide (SiO2) in a non-crystalline form, providing exceptional thermal resistance and optical clarity compared to standard glass, which typically contains a mix of silica, soda, and lime. Fused quartz's high silica content results in a melting point above 1700degC, significantly higher than the roughly 1400degC of standard soda-lime glass. The absence of added metallic oxides in fused quartz reduces internal stress and improves durability, distinguishing its composition from the more heterogeneous standard glass materials.

Manufacturing Processes Compared

Fused quartz is manufactured through melting high-purity silica sand at temperatures above 1700degC, creating a non-crystalline, homogenous structure with exceptional thermal and chemical resistance. Standard glass, commonly soda-lime glass, is produced by melting a mixture of silica, sodium carbonate, and lime at lower temperatures around 1500degC, resulting in a more amorphous and less purified material. The manufacturing process of fused quartz requires precise temperature control and longer cooling times, providing superior optical clarity and durability compared to the more cost-effective and mass-produced standard glass.

Optical Clarity and Light Transmission

Fused quartz offers superior optical clarity compared to standard glass, exhibiting minimal impurities and a highly uniform molecular structure that reduces light scattering. Its light transmission rate exceeds 90% across a broader spectrum, including ultraviolet and infrared wavelengths, unlike standard glass which tends to absorb more light in these ranges. This makes fused quartz ideal for applications requiring high precision optical performance and maximum light throughput.

Thermal Properties and Heat Resistance

Fused quartz exhibits superior thermal properties and heat resistance compared to standard glass, with a much lower coefficient of thermal expansion around 0.5 x 10^-6 /degC, enabling it to withstand rapid temperature changes without cracking. Its melting point exceeds 1700degC, significantly higher than standard soda-lime glass, which softens around 600-800degC, making fused quartz ideal for high-temperature applications. The exceptional thermal stability of fused quartz reduces internal stresses during heating and cooling cycles, enhancing durability in industrial and scientific environments.

Chemical Durability and Corrosion Resistance

Fused quartz exhibits superior chemical durability and corrosion resistance compared to standard glass due to its high purity and amorphous silica structure, which resists alkali and acid attacks more effectively. Its low impurity content minimizes leaching and surface degradation, making it ideal for harsh chemical environments and high-temperature applications. Standard glass, often composed of soda-lime silica, is more susceptible to corrosion and chemical wear, limiting its use in aggressive chemical settings.

Mechanical Strength and Hardness

Fused quartz exhibits superior mechanical strength and hardness compared to standard glass, making it more resistant to abrasion and mechanical stress. Its high purity and amorphous structure contribute to a higher Young's modulus and greater resistance to scratching. Standard glass, often containing impurities and crystalline phases, generally demonstrates lower mechanical durability and is more prone to surface damage under similar conditions.

Applications in Industry and Technology

Fused quartz exhibits superior thermal stability and chemical resistance compared to standard glass, making it ideal for high-temperature applications such as semiconductor manufacturing and laboratory equipment. Its low thermal expansion reduces the risk of cracking in precision optics and fiber optics used in telecommunications. Standard glass, while more cost-effective, is commonly employed in architectural, automotive, and everyday consumer products where such extreme performance characteristics are not critical.

Cost Analysis: Fused Quartz vs Standard Glass

Fused quartz commands a higher price point than standard glass due to its superior purity, thermal resistance, and durability, making it ideal for specialized applications. Standard glass remains more cost-effective for general uses, benefiting from mass production and lower raw material expenses. Evaluating the total cost of ownership involves considering longevity and performance, where fused quartz often justifies its initial investment through reduced maintenance and replacement costs.

Environmental Impact and Sustainability

Fused quartz offers superior environmental benefits compared to standard glass due to its higher durability and resistance to thermal shock, which reduces the frequency of replacements and waste generation. Its production process requires less energy because it can withstand higher temperatures without deforming, leading to lower carbon emissions and resource consumption. Fused quartz is also more recyclable, contributing to a circular economy and minimizing the overall environmental footprint of glass manufacturing.

Choosing the Right Material for Your Needs

Fused quartz offers superior thermal shock resistance and higher purity compared to standard glass, making it ideal for high-temperature applications and environments requiring exceptional optical clarity. Standard glass is generally more cost-effective and suitable for everyday uses such as windows and containers, where extreme durability is not critical. Selecting between fused quartz and standard glass depends on factors like temperature tolerance, optical performance, and budget constraints specific to your project's needs.

Fused quartz vs Standard glass Infographic

materialdif.com

materialdif.com