Cork composite offers superior moisture resistance and natural insulation compared to MDF, making it ideal for pet-friendly environments where durability and comfort are essential. Unlike MDF, which can swell and degrade when exposed to water, cork composite maintains its structural integrity and provides a softer, non-toxic surface suitable for pets. Its eco-friendly properties and hypoallergenic nature further enhance its appeal for pet owners seeking sustainable and safe materials.

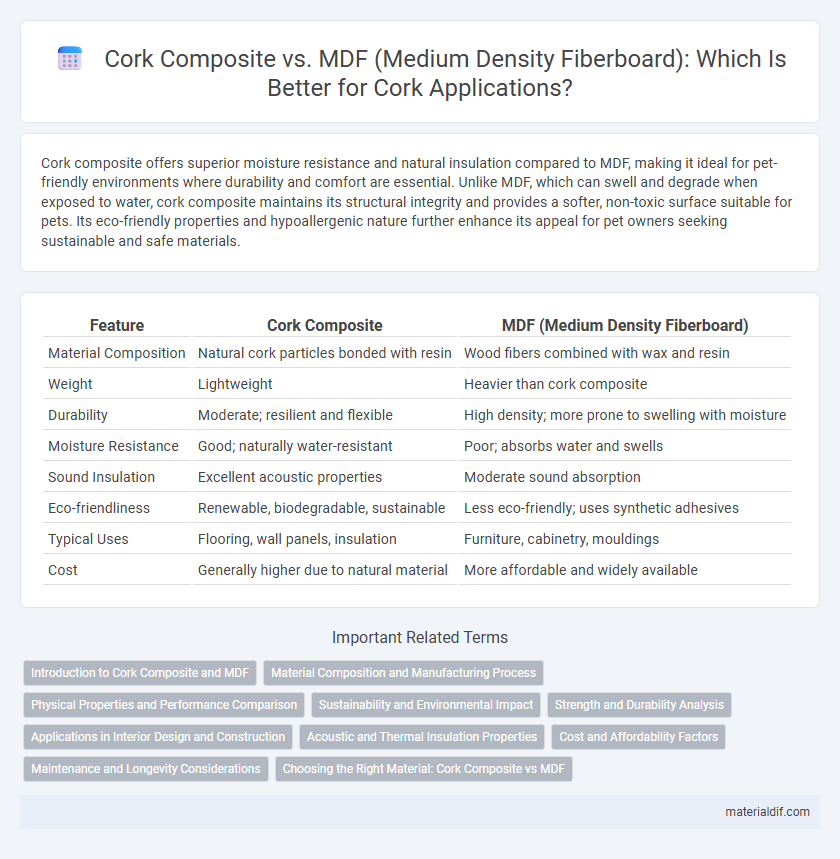

Table of Comparison

| Feature | Cork Composite | MDF (Medium Density Fiberboard) |

|---|---|---|

| Material Composition | Natural cork particles bonded with resin | Wood fibers combined with wax and resin |

| Weight | Lightweight | Heavier than cork composite |

| Durability | Moderate; resilient and flexible | High density; more prone to swelling with moisture |

| Moisture Resistance | Good; naturally water-resistant | Poor; absorbs water and swells |

| Sound Insulation | Excellent acoustic properties | Moderate sound absorption |

| Eco-friendliness | Renewable, biodegradable, sustainable | Less eco-friendly; uses synthetic adhesives |

| Typical Uses | Flooring, wall panels, insulation | Furniture, cabinetry, mouldings |

| Cost | Generally higher due to natural material | More affordable and widely available |

Introduction to Cork Composite and MDF

Cork composite is an eco-friendly material made by combining natural cork granules with binders, offering lightweight, moisture-resistant, and sound-insulating properties ideal for sustainable building and interior applications in Cork. Medium Density Fiberboard (MDF), produced from wood fibers combined with resin under heat and pressure, provides a smooth surface, consistent density, and versatility commonly used in furniture and cabinetry across Cork. Both materials serve distinct functions, with cork composite excelling in sustainability and acoustic performance, while MDF stands out for affordability and finish quality.

Material Composition and Manufacturing Process

Cork composite consists of natural cork granules combined with polyurethane resin, creating a lightweight, flexible, and eco-friendly material harvested from the bark of cork oak trees primarily in Portugal and Spain. In contrast, MDF (Medium Density Fiberboard) is engineered from wood fibers, wax, and resin, subjected to high temperature and pressure to form dense, uniform panels commonly produced worldwide, including in Cork's woodworking industry. The cork composite manufacturing emphasizes sustainable harvesting and minimal processing, whereas MDF production relies heavily on mechanical and chemical treatments, resulting in distinct textural and environmental properties.

Physical Properties and Performance Comparison

Cork offers superior elasticity and thermal insulation compared to MDF, making it ideal for environments requiring moisture resistance and sound absorption. MDF provides higher density and structural uniformity, resulting in better load-bearing capacity and smooth finish for detailed machining. Both materials vary significantly in durability; cork excels in resilience and comfort, while MDF is more prone to swelling and damage when exposed to water.

Sustainability and Environmental Impact

Cork composite offers superior sustainability compared to MDF (Medium Density Fiberboard) due to its renewable harvesting process and natural biodegradability, significantly reducing environmental impact. Cork is harvested from the bark of cork oak trees without harming the tree, allowing continuous regeneration and promoting carbon sequestration, whereas MDF production relies on synthetic resins and wood fibers, often contributing to deforestation and higher emissions. The low VOC emissions and recyclability of cork composite further enhance its eco-friendly profile, making it a preferable choice for environmentally conscious construction and design projects.

Strength and Durability Analysis

Cork offers superior resilience and natural elasticity compared to Medium Density Fiberboard (MDF), making it highly resistant to cracking and warping under pressure. MDF, while denser and smoother, tends to absorb moisture, which can weaken its structural integrity over time. Cork's cellular structure provides enhanced impact resistance and long-term durability, especially in environments prone to humidity and temperature fluctuations.

Applications in Interior Design and Construction

Cork composite offers superior acoustic insulation and natural moisture resistance, making it ideal for flooring and wall panels in interior design, especially in damp environments like kitchens and bathrooms. MDF is favored for its smooth surface and ease of painting, widely used in cabinetry, moldings, and furniture where detailed finishes are required. Both materials provide cost-effective solutions, but cork composite excels in sustainability and comfort, whereas MDF delivers versatility and structural uniformity in construction applications.

Acoustic and Thermal Insulation Properties

Cork offers superior acoustic insulation compared to MDF, effectively dampening sound due to its cellular structure that absorbs vibrations and reduces noise transmission. Its natural thermal insulation properties maintain stable indoor temperatures, outperforming MDF which has lower thermal resistance and tends to conduct heat more readily. Cork's sustainability and moisture resistance also contribute to its enhanced insulation performance in various construction applications.

Cost and Affordability Factors

Cork generally costs more per square foot than MDF, primarily due to its natural harvesting process and sustainability benefits. MDF offers a lower-cost alternative with consistent density and smooth surfaces, making it budget-friendly for large-scale projects. Affordability considerations often depend on project size, durability requirements, and eco-conscious preferences where cork's higher initial price may be offset by its longevity and insulation properties.

Maintenance and Longevity Considerations

Cork is naturally resistant to moisture and requires minimal maintenance, making it a durable option compared to MDF, which can swell and degrade when exposed to water. Cork's elasticity allows it to withstand wear and tear, extending its longevity in high-traffic areas, while MDF often needs sealing and careful upkeep to prevent damage. Properly maintained cork flooring or panels can last several decades, whereas MDF may require replacement or refinishing sooner due to its lower moisture resistance.

Choosing the Right Material: Cork Composite vs MDF

Cork composite offers superior moisture resistance and natural insulation properties compared to MDF, making it an ideal choice for environments prone to humidity. MDF provides a smooth, consistent surface that is easy to paint and shape, suited for indoor furniture and cabinetry in dry conditions. Selecting between cork composite and MDF depends on the specific application, durability requirements, and environmental exposure in Cork.

Cork composite vs MDF (Medium Density Fiberboard) Infographic

materialdif.com

materialdif.com