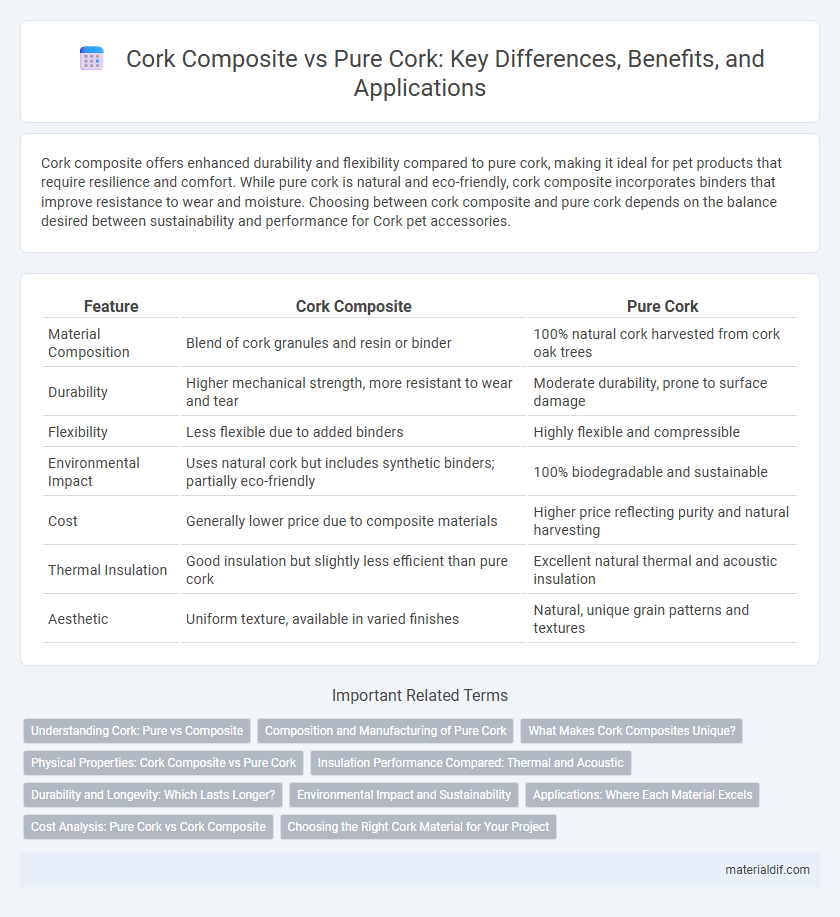

Cork composite offers enhanced durability and flexibility compared to pure cork, making it ideal for pet products that require resilience and comfort. While pure cork is natural and eco-friendly, cork composite incorporates binders that improve resistance to wear and moisture. Choosing between cork composite and pure cork depends on the balance desired between sustainability and performance for Cork pet accessories.

Table of Comparison

| Feature | Cork Composite | Pure Cork |

|---|---|---|

| Material Composition | Blend of cork granules and resin or binder | 100% natural cork harvested from cork oak trees |

| Durability | Higher mechanical strength, more resistant to wear and tear | Moderate durability, prone to surface damage |

| Flexibility | Less flexible due to added binders | Highly flexible and compressible |

| Environmental Impact | Uses natural cork but includes synthetic binders; partially eco-friendly | 100% biodegradable and sustainable |

| Cost | Generally lower price due to composite materials | Higher price reflecting purity and natural harvesting |

| Thermal Insulation | Good insulation but slightly less efficient than pure cork | Excellent natural thermal and acoustic insulation |

| Aesthetic | Uniform texture, available in varied finishes | Natural, unique grain patterns and textures |

Understanding Cork: Pure vs Composite

Pure cork is harvested directly from the bark of the cork oak tree, maintaining its natural cellular structure which provides superior insulation, elasticity, and durability. Composite cork combines natural cork granules with binders or other materials, offering enhanced versatility and cost-effectiveness while slightly compromising the inherent breathability and resilience of pure cork. Understanding the distinction between pure and composite cork is essential for selecting the appropriate material based on application needs such as flooring, insulation, or decorative purposes.

Composition and Manufacturing of Pure Cork

Cork composite consists of cork granules mixed with synthetic resins or binders, enhancing flexibility and durability for various applications. Pure cork is harvested directly from the bark of the cork oak tree, composed mainly of suberin, lignin, and cellulose, and undergoes a natural drying and pressing process without chemical additives. Manufacturing pure cork involves carefully stripping the bark, boiling to increase elasticity, and flattening it into sheets, preserving its natural cellular structure for insulation and sustainability.

What Makes Cork Composites Unique?

Cork composites combine natural cork granules with binding agents, offering enhanced durability and flexibility compared to pure cork. This hybrid structure improves impact resistance and thermal insulation while maintaining cork's natural breathability. The unique blend allows for tailored properties in flooring, insulation panels, and acoustic solutions, making cork composites versatile for various applications.

Physical Properties: Cork Composite vs Pure Cork

Cork composite combines natural cork granules with synthetic binders, resulting in enhanced durability, higher density, and improved impact resistance compared to pure cork. Pure cork offers excellent elasticity, thermal insulation, and water resistance due to its unique cellular structure but is more prone to wear and deformation under heavy stress. The choice between cork composite and pure cork depends on specific application requirements, balancing the natural properties of pure cork against the reinforced strength of composites.

Insulation Performance Compared: Thermal and Acoustic

Cork composite materials exhibit enhanced thermal insulation properties compared to pure cork, due to the integration of other materials that reduce heat transfer and improve energy efficiency. Acoustic insulation in cork composites also outperforms pure cork by effectively dampening a wider range of frequencies, resulting in superior soundproofing performance in building applications. Pure cork remains highly effective in natural thermal and acoustic insulation but lacks the amplified resistance achieved by engineered composites.

Durability and Longevity: Which Lasts Longer?

Cork composite offers enhanced durability compared to pure cork, as it combines natural cork granules with binders that increase resistance to wear and tear. Pure cork provides excellent natural resilience and flexibility but is more susceptible to damage from moisture and heavy use over time. In terms of longevity, cork composite generally lasts longer in high-traffic or demanding environments, while pure cork is ideal for applications prioritizing natural aesthetics and moderate durability.

Environmental Impact and Sustainability

Cork Composite combines natural cork with synthetic materials, reducing overall cork consumption but introducing non-biodegradable elements that complicate recycling and increase environmental footprint. Pure Cork is fully biodegradable and harvested from the renewable bark of cork oak trees without harming them, promoting sustainable forestry practices and carbon sequestration. Choosing Pure Cork supports ecosystem preservation and waste reduction, making it a more environmentally sustainable option compared to Cork Composite.

Applications: Where Each Material Excels

Cork composite offers enhanced durability and flexibility, making it ideal for flooring, insulation, and automotive applications where strength and resilience are critical. Pure cork provides superior natural elasticity and moisture resistance, excelling in products such as wine stoppers, bulletin boards, and acoustic panels. The choice between cork composite and pure cork depends on the specific performance requirements of each application.

Cost Analysis: Pure Cork vs Cork Composite

Pure cork offers superior durability and natural insulation but incurs higher costs due to its limited supply and labor-intensive harvesting process. Cork composite, made from cork granules mixed with synthetic resins or binders, provides a more affordable alternative while maintaining reasonable performance for flooring and insulation applications. Cost analysis shows cork composite can reduce expenses by up to 40% compared to pure cork, making it a budget-friendly option without significantly compromising on environmental benefits.

Choosing the Right Cork Material for Your Project

Cork composite combines natural cork with resins or polymers, enhancing durability and flexibility for high-traffic or moisture-prone environments, whereas pure cork offers exceptional natural insulation and sustainability benefits ideal for eco-friendly projects. Selecting the right cork material depends on the specific application requirements, such as soundproofing, thermal insulation, or resistance to wear and tear. For flooring and wall coverings in commercial spaces, cork composite provides superior longevity, while pure cork excels in residential or decorative uses where natural texture and environmental impact are priorities.

Cork Composite vs Pure Cork Infographic

materialdif.com

materialdif.com