Flexible cork offers superior adaptability in applications requiring cushioning and sound insulation due to its compressible nature, making it ideal for flooring underlays and gaskets. Rigid cork, characterized by its solid and dense structure, provides excellent structural support and thermal insulation, commonly used in wall panels and insulation boards. Understanding the distinct mechanical properties of flexible and rigid cork is essential for selecting the right material to optimize durability and performance in construction and design projects.

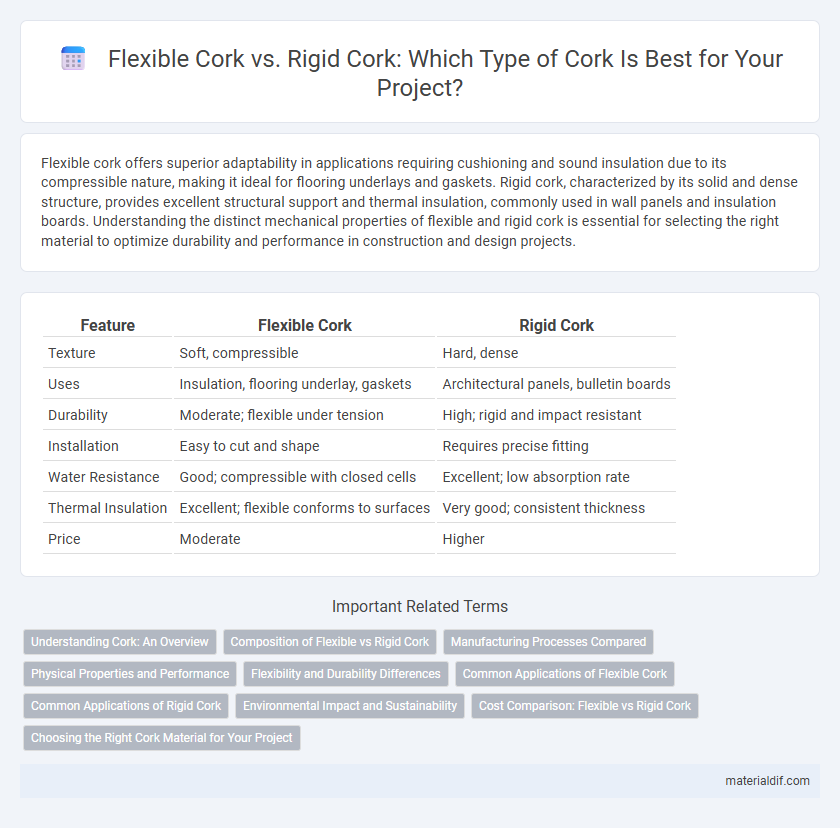

Table of Comparison

| Feature | Flexible Cork | Rigid Cork |

|---|---|---|

| Texture | Soft, compressible | Hard, dense |

| Uses | Insulation, flooring underlay, gaskets | Architectural panels, bulletin boards |

| Durability | Moderate; flexible under tension | High; rigid and impact resistant |

| Installation | Easy to cut and shape | Requires precise fitting |

| Water Resistance | Good; compressible with closed cells | Excellent; low absorption rate |

| Thermal Insulation | Excellent; flexible conforms to surfaces | Very good; consistent thickness |

| Price | Moderate | Higher |

Understanding Cork: An Overview

Flexible cork offers superior elasticity and compressibility, making it ideal for applications requiring cushioning, sealing, and insulation, such as gaskets and footwear. Rigid cork provides structural strength and durability, commonly used in flooring, wall panels, and bulletin boards due to its firm texture and longevity. Understanding the distinct properties of flexible versus rigid cork enables optimized selection based on the specific mechanical and environmental demands of each application.

Composition of Flexible vs Rigid Cork

Flexible cork consists primarily of thin, elastic granules bound together by natural resins, allowing for adaptability and compressibility, ideal for insulation and cushioning. Rigid cork is composed of tightly packed, denser cork cells with minimal resin content, providing enhanced structural strength and durability for flooring and wall panels. The variance in cellular density and resin distribution defines the distinct mechanical properties and applications of flexible versus rigid cork materials.

Manufacturing Processes Compared

Flexible cork is produced using granulated cork particles mixed with polyurethane or other binders through a steam molding process, resulting in lightweight, elastic sheets ideal for flooring and insulation. Rigid cork is manufactured by compressing natural cork slabs under high pressure and heat, eliminating binders and preserving cork's cellular structure for strong, durable blocks used in construction and industrial applications. The key manufacturing difference lies in flexible cork's use of adhesives and molding techniques versus rigid cork's direct compression, influencing their mechanical properties and suitability for various purposes.

Physical Properties and Performance

Flexible cork exhibits superior elasticity and compressibility compared to rigid cork, allowing it to absorb shocks and vibrations more effectively, making it ideal for insulation and flooring applications. Rigid cork, with higher density and structural strength, offers greater load-bearing capacity and dimensional stability, suitable for construction and industrial uses. Both types provide excellent thermal and acoustic insulation, but flexible cork outperforms in flexibility and adaptability, while rigid cork excels in durability and resistance.

Flexibility and Durability Differences

Flexible cork offers superior adaptability and resilience, making it ideal for applications requiring bending and compression without cracking. Rigid cork provides higher structural strength and long-lasting durability under stationary weight or pressure but lacks the elasticity of flexible cork. The choice between flexible and rigid cork depends on balancing the need for flexibility with the requirement for load-bearing endurance in cork products.

Common Applications of Flexible Cork

Flexible cork, known for its compressibility and elasticity, is commonly used in flooring underlays, insulation, and vibration dampening materials. It provides excellent thermal and acoustic insulation in residential and commercial buildings while adapting easily to uneven surfaces. This versatility makes flexible cork a preferred choice for expansion joints, gaskets, and cushioning in furniture manufacturing.

Common Applications of Rigid Cork

Rigid cork is widely used in flooring solutions due to its durability, thermal insulation, and sound absorption properties, making it ideal for residential and commercial buildings. It is also commonly employed in wall panels and insulation boards, providing moisture resistance and fire retardancy that enhance energy efficiency and safety. Additionally, rigid cork serves as a sustainable material in furniture manufacturing and bulletin boards, valued for its lightweight yet sturdy nature.

Environmental Impact and Sustainability

Flexible cork offers superior sustainability compared to rigid cork due to its lower processing energy and higher recyclability, reducing overall carbon emissions. The renewable nature of cork oak trees ensures minimal environmental disruption, with flexible cork products often sourced from bark harvested without harming the tree. Rigid cork typically requires more intensive manufacturing, increasing waste and energy use, which impacts its eco-friendliness relative to flexible cork alternatives.

Cost Comparison: Flexible vs Rigid Cork

Flexible cork generally costs more per square foot than rigid cork due to its enhanced elasticity and durability, making it ideal for applications requiring movement and compression. Rigid cork offers a more budget-friendly option with lower upfront costs but may require more frequent replacement in areas subject to stress or impact. Evaluating long-term expenses, flexible cork often provides better value by reducing maintenance and replacement frequency despite the higher initial investment.

Choosing the Right Cork Material for Your Project

Flexible cork offers superior adaptability and cushioning, ideal for applications requiring elasticity and dynamic movement such as flooring underlays and gaskets. Rigid cork provides enhanced structural support and durability, making it suitable for insulation panels and architectural elements where stiffness is crucial. Selecting the appropriate cork material depends on balancing factors like load-bearing needs, environmental exposure, and desired flexibility to ensure optimal performance in your project.

Flexible Cork vs Rigid Cork Infographic

materialdif.com

materialdif.com