Cork plugs offer a natural, biodegradable solution ideal for sealing bottles and containers, providing a tight yet breathable seal that is perfect for wine and artisanal products. Rubber plugs, on the other hand, deliver superior flexibility and durability, making them suitable for laboratory use and industrial applications where a more resilient and reusable stopper is needed. Choosing between cork plugs and rubber plugs depends on the specific requirements for sealing, environmental impact, and ease of removal.

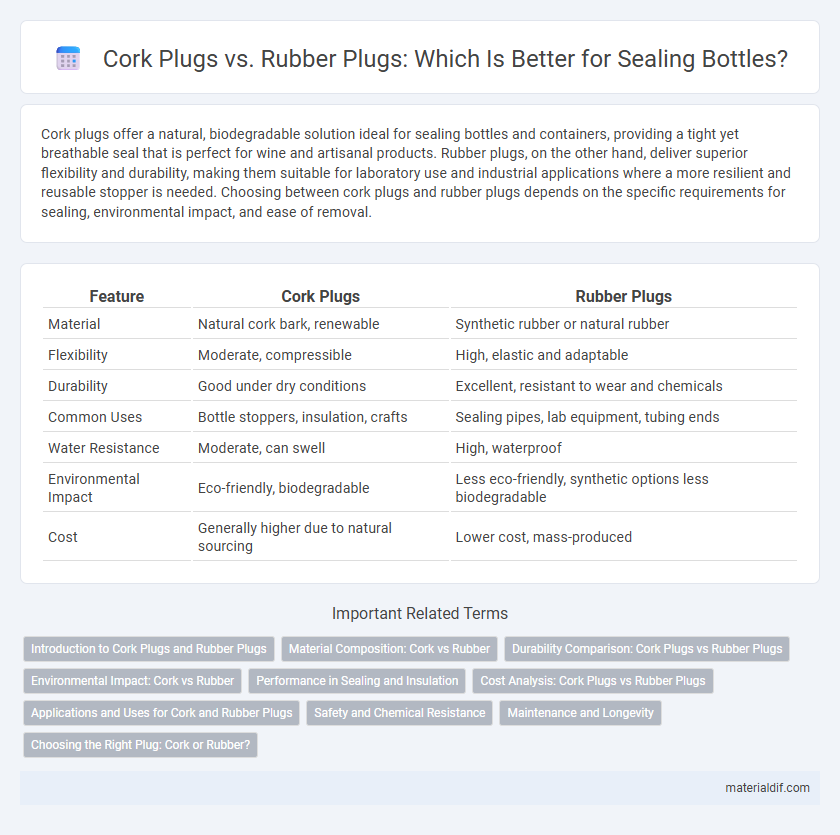

Table of Comparison

| Feature | Cork Plugs | Rubber Plugs |

|---|---|---|

| Material | Natural cork bark, renewable | Synthetic rubber or natural rubber |

| Flexibility | Moderate, compressible | High, elastic and adaptable |

| Durability | Good under dry conditions | Excellent, resistant to wear and chemicals |

| Common Uses | Bottle stoppers, insulation, crafts | Sealing pipes, lab equipment, tubing ends |

| Water Resistance | Moderate, can swell | High, waterproof |

| Environmental Impact | Eco-friendly, biodegradable | Less eco-friendly, synthetic options less biodegradable |

| Cost | Generally higher due to natural sourcing | Lower cost, mass-produced |

Introduction to Cork Plugs and Rubber Plugs

Cork plugs, derived from the bark of cork oak trees, offer natural elasticity and water resistance, making them ideal for sealing bottles and containers in various industries. Rubber plugs, made from synthetic or natural rubber, provide superior flexibility and chemical resistance, suitable for airtight seals in laboratory and industrial applications. Both cork and rubber plugs serve essential sealing functions, with cork favored for its eco-friendly properties and rubber prized for durability under harsh conditions.

Material Composition: Cork vs Rubber

Cork plugs are made from natural bark harvested from cork oak trees, offering a lightweight, biodegradable, and breathable material that resists moisture without deforming. Rubber plugs consist of synthetic or natural rubber compounds, providing greater elasticity, durability, and a tighter seal in applications demanding flexibility and chemical resistance. The choice between cork and rubber plugs depends on factors such as environmental impact, sealing requirements, and exposure to chemicals or extreme temperatures.

Durability Comparison: Cork Plugs vs Rubber Plugs

Cork plugs offer moderate durability with natural resistance to moisture and wear, making them suitable for traditional wine bottles and craft applications. Rubber plugs provide superior durability due to their elasticity and resistance to harsh chemicals, ensuring a longer lifespan in industrial and laboratory settings. When comparing both, rubber plugs outperform cork plugs in longevity and resilience under repeated use and exposure to diverse environments.

Environmental Impact: Cork vs Rubber

Cork plugs are environmentally favorable due to their renewable sourcing from cork oak tree bark, which is harvested without harming the tree and supports carbon sequestration. Rubber plugs, typically derived from synthetic materials or non-sustainably harvested natural rubber, have a larger carbon footprint and contribute to pollution during production and disposal. Choosing cork plugs over rubber plugs reduces environmental impact by promoting biodiversity, decreasing waste, and supporting sustainable forestry practices.

Performance in Sealing and Insulation

Cork plugs offer superior sealing performance due to their natural compressibility and ability to conform to irregular surfaces, making them ideal for airtight and watertight applications. Rubber plugs provide excellent insulation properties, particularly for thermal and electrical uses, due to their inherent elasticity and resistance to environmental factors. Cork excels in breathability and moisture resistance, while rubber plugs are more durable and provide better chemical resistance in demanding conditions.

Cost Analysis: Cork Plugs vs Rubber Plugs

Cork plugs in Cork generally offer a more cost-effective solution compared to rubber plugs, primarily due to the natural availability of cork in the region. Rubber plugs tend to have higher manufacturing and material costs, reflecting in their retail prices. When considering long-term use and environmental factors, cork plugs provide both affordability and sustainability benefits.

Applications and Uses for Cork and Rubber Plugs

Cork plugs excel in wine bottling and craft projects due to their natural elasticity and breathability, allowing for secure sealing while permitting minimal air exchange. Rubber plugs are preferred in laboratory and industrial applications where chemical resistance, flexibility, and reusability are critical, effectively sealing flasks and test tubes against liquids and gases. Both cork and rubber plugs offer distinct advantages depending on the environment and specific sealing requirements, impacting their selection in food, beverage, or scientific industries.

Safety and Chemical Resistance

Cork plugs offer excellent sealing properties and moderate chemical resistance, making them suitable for applications involving mild acids and solvents, but they may deteriorate with prolonged exposure to harsh chemicals. Rubber plugs provide superior chemical resistance and durability, ensuring enhanced safety when dealing with aggressive substances like strong acids, alkalis, and solvents. Selecting between cork and rubber plugs depends on specific chemical compatibility requirements and the need for leak-proof containment in laboratory or industrial environments.

Maintenance and Longevity

Cork plugs in Cork offer natural resistance to moisture and mold, requiring minimal maintenance while providing excellent breathability for stored wines. Rubber plugs, though easier to clean and more durable against physical wear, may degrade faster under prolonged exposure to heat and chemicals. Choosing cork plugs ensures longer-term longevity with lower upkeep, especially in Cork's temperate climate.

Choosing the Right Plug: Cork or Rubber?

Choosing the right plug involves comparing the natural sap properties of cork plugs with the flexible, airtight qualities of rubber plugs. Cork plugs offer superior breathability and are ideal for preserving wine aromas, while rubber plugs provide a tighter seal better suited for laboratory and industrial use. Selecting between cork and rubber plugs depends on the desired airtightness, chemical resistance, and application environment.

Cork Plugs vs Rubber Plugs Infographic

materialdif.com

materialdif.com