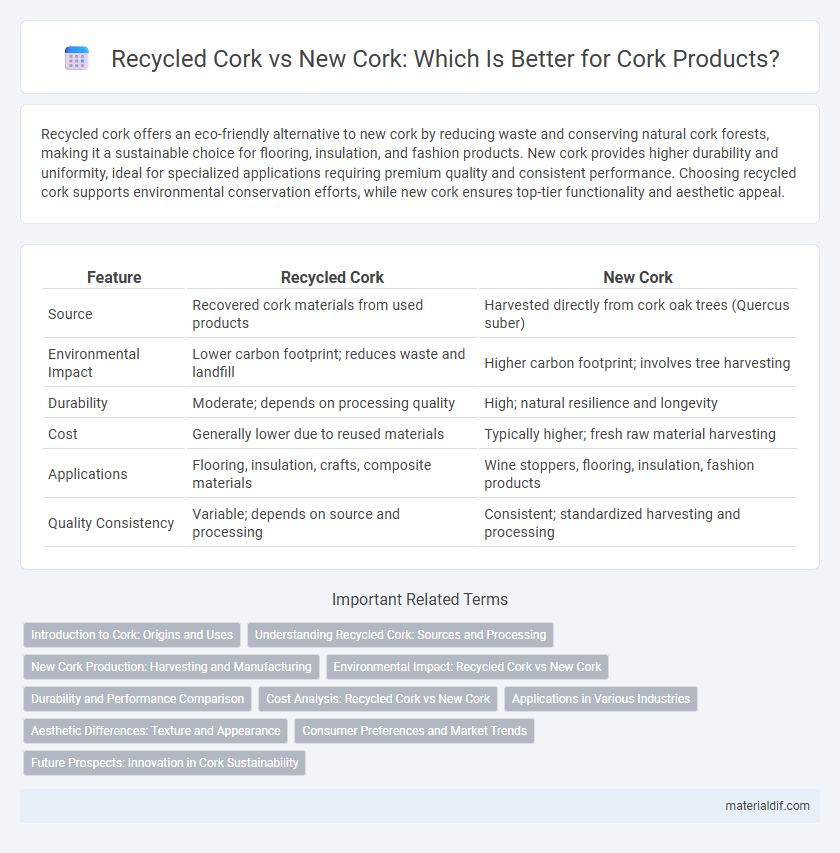

Recycled cork offers an eco-friendly alternative to new cork by reducing waste and conserving natural cork forests, making it a sustainable choice for flooring, insulation, and fashion products. New cork provides higher durability and uniformity, ideal for specialized applications requiring premium quality and consistent performance. Choosing recycled cork supports environmental conservation efforts, while new cork ensures top-tier functionality and aesthetic appeal.

Table of Comparison

| Feature | Recycled Cork | New Cork |

|---|---|---|

| Source | Recovered cork materials from used products | Harvested directly from cork oak trees (Quercus suber) |

| Environmental Impact | Lower carbon footprint; reduces waste and landfill | Higher carbon footprint; involves tree harvesting |

| Durability | Moderate; depends on processing quality | High; natural resilience and longevity |

| Cost | Generally lower due to reused materials | Typically higher; fresh raw material harvesting |

| Applications | Flooring, insulation, crafts, composite materials | Wine stoppers, flooring, insulation, fashion products |

| Quality Consistency | Variable; depends on source and processing | Consistent; standardized harvesting and processing |

Introduction to Cork: Origins and Uses

Cork, harvested primarily from the bark of the Quercus suber tree native to the Mediterranean region, offers sustainable and versatile applications. Recycled cork retains its natural properties and significantly reduces environmental impact compared to new cork, which requires fresh bark harvesting that can affect tree health. Both types serve in diverse uses such as wine stoppers, flooring, insulation, and fashion accessories.

Understanding Recycled Cork: Sources and Processing

Recycled cork is primarily sourced from used wine stoppers, cork flooring scraps, and manufacturing by-products, which undergo shredding and sterilization to remove impurities. This environmentally sustainable process reduces waste by repurposing cork granules for insulation, flooring, and craft products while maintaining many of the elastic and fire-resistant properties of virgin cork. Advances in adhesive-free binding techniques enhance the durability and eco-friendliness of recycled cork materials compared to traditional cork production.

New Cork Production: Harvesting and Manufacturing

New cork production begins with the careful harvesting of cork oak tree bark, primarily in Mediterranean regions such as Portugal and Spain, where environmental sustainability is strictly maintained to ensure the tree's regrowth. The manufacturing process involves boiling the harvested cork slabs to remove impurities and increase elasticity, followed by drying and cutting into various granules or sheets used in wine stoppers, flooring, and insulation. Technological advancements in cork processing optimize material properties, enhancing durability and performance while preserving the natural cellular structure critical for cork's lightweight and compressible qualities.

Environmental Impact: Recycled Cork vs New Cork

Recycled cork significantly reduces environmental impact by minimizing waste and lowering the demand for new cork harvesting, which helps preserve cork oak forests vital for biodiversity and carbon sequestration. New cork production involves harvesting the bark from cork oak trees, a sustainable practice if done every 9-12 years, but it still requires more energy and resources compared to using recycled cork. Choosing recycled cork supports circular economy principles, reduces landfill waste, and decreases carbon emissions associated with processing raw cork materials.

Durability and Performance Comparison

Recycled cork demonstrates impressive durability, maintaining structural integrity while reducing environmental impact compared to new cork. New cork offers superior performance in terms of elasticity and moisture resistance, making it ideal for high-stress applications like flooring and insulation. Both materials provide sustainable options, but new cork typically ensures longer-lasting performance in demanding environments.

Cost Analysis: Recycled Cork vs New Cork

Recycled cork offers a cost-effective alternative to new cork by significantly reducing raw material expenses and lowering production costs through sustainable repurposing processes. New cork, sourced directly from cork oak trees primarily in regions like Portugal and Spain, incurs higher costs due to harvesting and processing requirements. Businesses prioritizing budget efficiency and environmental sustainability often prefer recycled cork for its balance of affordability and eco-friendly benefits.

Applications in Various Industries

Recycled cork offers sustainable advantages in industries such as construction, fashion, and automotive by providing eco-friendly insulation, lightweight materials, and durable components. New cork remains preferred in premium wine stoppers, musical instruments, and high-performance flooring due to its superior elasticity and natural grain consistency. Both forms support innovation, with recycled cork reducing environmental impact while new cork ensures maximum material integrity.

Aesthetic Differences: Texture and Appearance

Recycled cork features a more rustic texture with visible granules and natural imperfections, creating a unique, organic appearance ideal for eco-conscious designs. New cork, on the other hand, offers a smoother, more uniform surface with consistent color and fewer blemishes, enhancing sleek and modern aesthetics. These textural and visual contrasts allow designers to select cork that best suits either a natural or polished interior style.

Consumer Preferences and Market Trends

Consumer preferences increasingly favor recycled cork due to its sustainability and environmental benefits, driving growth in eco-conscious market segments. New cork remains popular for premium applications requiring uniformity and durability, particularly in luxury wine closures and high-end flooring. Market trends indicate a rising demand for recycled cork products in construction and fashion industries, reflecting a shift towards circular economy principles.

Future Prospects: Innovation in Cork Sustainability

Recycled cork is transforming the sustainability landscape in Cork by reducing waste and lowering carbon emissions compared to new cork production. Innovations such as advanced recycling technologies and eco-friendly adhesives enhance the durability and versatility of recycled cork products. Future prospects emphasize circular economy models, integrating recycled cork into construction, fashion, and automotive industries for a more sustainable future.

Recycled Cork vs New Cork Infographic

materialdif.com

materialdif.com