Cork granules offer greater flexibility and are ideal for filling uneven surfaces or creating custom shapes, making them perfect for pet bedding or play areas. Cork blocks provide sturdy support and durability, suitable for pet scratching posts or furniture bases. Choosing between cork granules and blocks depends on whether cushioning or structural strength is the priority.

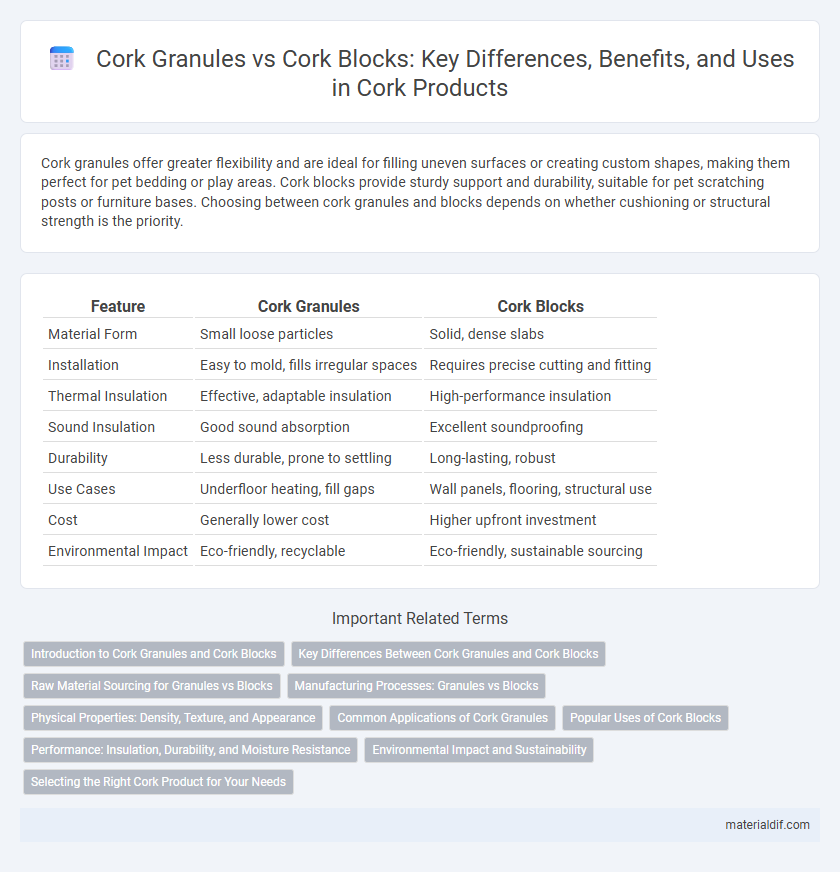

Table of Comparison

| Feature | Cork Granules | Cork Blocks |

|---|---|---|

| Material Form | Small loose particles | Solid, dense slabs |

| Installation | Easy to mold, fills irregular spaces | Requires precise cutting and fitting |

| Thermal Insulation | Effective, adaptable insulation | High-performance insulation |

| Sound Insulation | Good sound absorption | Excellent soundproofing |

| Durability | Less durable, prone to settling | Long-lasting, robust |

| Use Cases | Underfloor heating, fill gaps | Wall panels, flooring, structural use |

| Cost | Generally lower cost | Higher upfront investment |

| Environmental Impact | Eco-friendly, recyclable | Eco-friendly, sustainable sourcing |

Introduction to Cork Granules and Cork Blocks

Cork granules are small, irregularly shaped pieces derived from crushed cork bark, commonly used for insulation, packing, and cushioning due to their lightweight and flexible nature. Cork blocks, on the other hand, are larger, solid pieces of cork that offer greater density and structural strength, making them ideal for flooring, wall panels, and soundproofing applications. Both cork granules and blocks provide sustainable, renewable materials with excellent thermal and acoustic properties, essential in eco-friendly construction and design in Cork.

Key Differences Between Cork Granules and Cork Blocks

Cork granules are small, loose particles typically used for insulation, flooring underlays, and composite materials due to their flexibility and ease of application, whereas cork blocks are solid, dense pieces ideal for structural uses, furniture, and crafts requiring durability. Granules offer better thermal and acoustic insulation by filling gaps and providing cushioning, while blocks provide enhanced mechanical strength and can be easily carved or shaped. The choice between cork granules and cork blocks depends on the specific application requirements for density, strength, and ease of installation in Cork-related construction or design projects.

Raw Material Sourcing for Granules vs Blocks

Cork granules are primarily sourced from reclaimed or recycled cork waste, such as used wine stoppers, ensuring sustainable utilization of raw materials. In contrast, cork blocks are produced from whole, high-quality cork planks harvested directly from the cork oak tree (Quercus suber) bark during periodic debarking cycles. The raw material sourcing for granules emphasizes environmental efficiency by repurposing byproducts, whereas blocks rely on fresh cork extraction for premium structural integrity.

Manufacturing Processes: Granules vs Blocks

Cork granules are produced by grinding cork bark into small, irregular pieces, allowing for flexible usage in composite materials and insulation. Cork blocks, on the other hand, are manufactured by compressing larger cork slabs under heat and pressure to form dense, solid shapes ideal for flooring and stoppers. The granulation process enhances versatility and elasticity, while block manufacturing offers durability and structural integrity for construction applications.

Physical Properties: Density, Texture, and Appearance

Cork granules exhibit lower density compared to cork blocks, making them ideal for lightweight applications and insulation purposes; their fine, irregular texture allows for versatile molding and layering. Cork blocks are denser and provide a robust, uniform structure with a smooth, consistent grain, enhancing durability and structural integrity. The appearance of cork granules is more granular and varied, while cork blocks showcase a cohesive, natural woody look favored in architectural finishes.

Common Applications of Cork Granules

Cork granules are widely used in insulating materials for flooring, providing excellent thermal and acoustic properties in residential and commercial buildings. These granules are commonly incorporated into composite boards and underlayment products to enhance shock absorption and durability. Their versatility also extends to being a key ingredient in sports equipment and decorative finishes, benefiting from cork's natural elasticity and resilience.

Popular Uses of Cork Blocks

Cork blocks are widely used in construction and interior design due to their superior durability, insulating properties, and ease of handling compared to cork granules. Popular applications include wall panels, flooring underlays, and soundproofing solutions where solid, dense material is essential. Their consistency and structural strength make cork blocks ideal for both residential and commercial projects seeking sustainable, eco-friendly materials.

Performance: Insulation, Durability, and Moisture Resistance

Cork granules provide superior thermal insulation and enhanced flexibility, making them ideal for filling gaps and irregular spaces, while cork blocks offer higher durability and structural stability for load-bearing applications. Both materials exhibit excellent moisture resistance due to cork's natural cellular structure, but cork blocks tend to have better long-term performance in damp environments because of their density. Choosing between cork granules and blocks depends on the specific insulation needs, with granules excelling in adaptability and blocks in longevity and robustness.

Environmental Impact and Sustainability

Cork granules and cork blocks both offer eco-friendly options, but granules have a lower carbon footprint due to their use in insulation and lightweight composites, reducing material waste. Cork blocks, while durable and highly sustainable from harvested cork oak trees, often require more energy-intensive processing and transportation. Choosing cork granules supports circular economy principles by recycling cork waste, enhancing resource efficiency compared to solid cork blocks.

Selecting the Right Cork Product for Your Needs

Cork granules offer excellent versatility for insulation, cushioning, and decorative purposes due to their lightweight and easily moldable properties, making them ideal for DIY projects and unique designs. Cork blocks provide superior density and durability, often used in flooring, wall panels, and structural applications where strength and longevity are critical. Selecting between Cork granules and Cork blocks depends on your project's requirements for flexibility, thermal insulation, or load-bearing capacity.

Cork Granules vs Cork Blocks Infographic

materialdif.com

materialdif.com