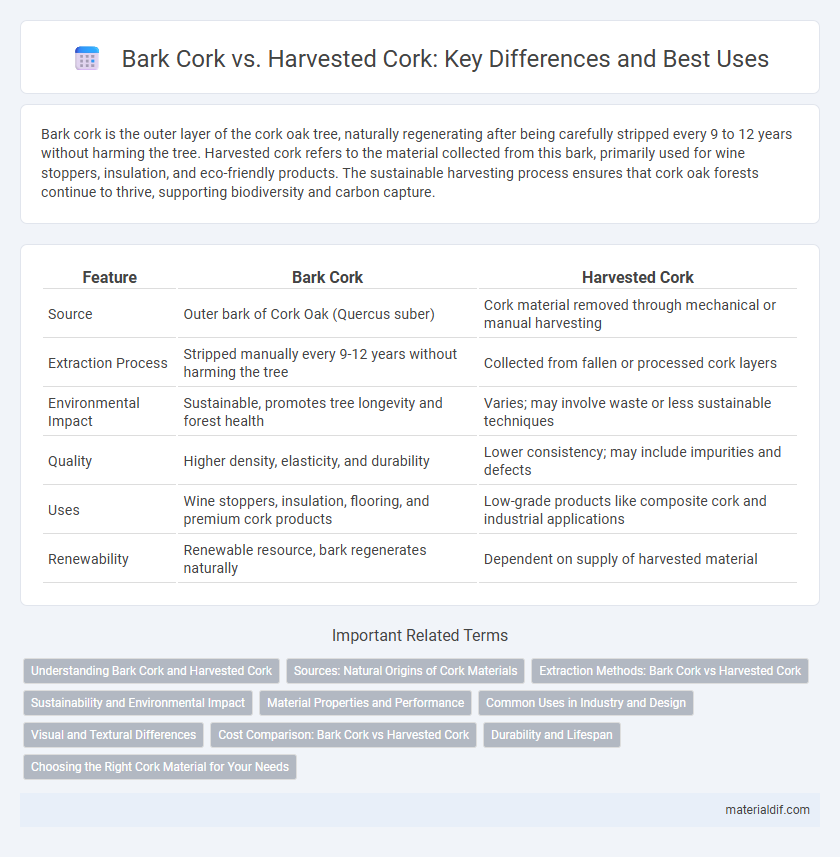

Bark cork is the outer layer of the cork oak tree, naturally regenerating after being carefully stripped every 9 to 12 years without harming the tree. Harvested cork refers to the material collected from this bark, primarily used for wine stoppers, insulation, and eco-friendly products. The sustainable harvesting process ensures that cork oak forests continue to thrive, supporting biodiversity and carbon capture.

Table of Comparison

| Feature | Bark Cork | Harvested Cork |

|---|---|---|

| Source | Outer bark of Cork Oak (Quercus suber) | Cork material removed through mechanical or manual harvesting |

| Extraction Process | Stripped manually every 9-12 years without harming the tree | Collected from fallen or processed cork layers |

| Environmental Impact | Sustainable, promotes tree longevity and forest health | Varies; may involve waste or less sustainable techniques |

| Quality | Higher density, elasticity, and durability | Lower consistency; may include impurities and defects |

| Uses | Wine stoppers, insulation, flooring, and premium cork products | Low-grade products like composite cork and industrial applications |

| Renewability | Renewable resource, bark regenerates naturally | Dependent on supply of harvested material |

Understanding Bark Cork and Harvested Cork

Bark cork refers to the outer layer of the cork oak tree, naturally harvested without harming the tree, ensuring sustainability and long-term production. Harvested cork involves the manual stripping of this bark every 9 to 12 years, allowing the tree to regenerate its bark for future harvests. This cyclical process makes cork an eco-friendly material used widely in wine stoppers, flooring, and insulation.

Sources: Natural Origins of Cork Materials

Bark cork is sourced from the outer bark of the cork oak tree (Quercus suber), harvested sustainably without cutting down the tree, allowing for natural regeneration every 9 to 12 years. Harvested cork involves removing cork material directly from the tree's bark in Mediterranean regions like Portugal and Spain, where cork oak forests are abundant. Both sources emphasize eco-friendly practices, preserving biodiversity and supporting cork oak ecosystems essential to the natural origins of cork materials.

Extraction Methods: Bark Cork vs Harvested Cork

Bark cork extraction involves carefully stripping the outer bark of the cork oak tree without harming the inner layers, allowing the tree to regenerate bark over several years. Harvested cork, in contrast, refers to the cork material collected after the bark is fully removed and processed, typically involving drying and boiling to enhance its properties. The sustainable bark stripping method ensures continuous cork production without tree felling, whereas harvested cork represents the final raw material ready for manufacturing cork products.

Sustainability and Environmental Impact

Bark cork is harvested by carefully stripping only the outer bark layer from cork oak trees, allowing the trees to regenerate and continue absorbing carbon dioxide, making it a highly sustainable and environmentally friendly practice. Harvested cork, often referring to cork obtained through more intensive methods or clear-cutting, can disrupt ecosystems and reduce biodiversity, resulting in a greater environmental impact. Sustainable cork harvesting supports soil preservation, wildlife habitats, and carbon sequestration, positioning bark cork as a preferred choice for eco-conscious industries.

Material Properties and Performance

Bark cork, known for its natural elasticity and thermal insulation, maintains superior resilience due to minimal processing, making it ideal for applications requiring flexibility and moisture resistance. Harvested cork, processed from stripped bark, exhibits enhanced durability and hardness, suitable for structural uses where compression strength and longevity are paramount. Both materials offer renewable, lightweight, and fire-retardant properties but differ in texture and performance, influencing their selection based on specific engineering and design needs.

Common Uses in Industry and Design

Bark cork, primarily harvested from the outer layer of the cork oak tree, is extensively used in insulation, flooring, and acoustic panels due to its lightweight, compressible, and water-resistant properties. Harvested cork, often processed into granules or sheets, finds common applications in wine stoppers, bulletin boards, and fashion accessories, benefiting from its durability and natural elasticity. Both materials leverage cork's sustainable and renewable qualities, making them popular choices in eco-friendly design and industrial products.

Visual and Textural Differences

Bark cork displays a more rugged, naturally textured surface with visible grain patterns and occasional knots, giving it an organic, rustic appearance. Harvested cork is typically smoother and more uniform in texture, often processed to remove imperfections for a refined, consistent finish. Visually, bark cork maintains irregularities and depth, while harvested cork emphasizes a polished, cleaner look suitable for various design applications.

Cost Comparison: Bark Cork vs Harvested Cork

Bark cork typically incurs higher costs due to its sustainable harvesting methods and lower yield per tree compared to harvested cork, which involves stripping the bark and allows for multiple harvests over a tree's lifetime. Harvested cork offers more cost efficiency by maximizing cork production through periods of regrowth every 9-12 years, reducing long-term expenses for suppliers. Price variations depend on the cork's quality, processing techniques, and market demand, with bark cork often commanding premium prices for its eco-friendly attributes.

Durability and Lifespan

Bark cork, harvested from the outer layer of cork oak trees without cutting the tree down, offers superior durability due to its natural elasticity and resistance to moisture and wear. Harvested cork, typically obtained through more invasive methods, tends to have a shorter lifespan as it may compromise the structural integrity of the material. The sustainable extraction process of bark cork ensures a longer-lasting product, maintaining its resilience over decades compared to conventional harvested cork.

Choosing the Right Cork Material for Your Needs

Bark cork, derived directly from the outer layer of the cork oak tree, offers natural elasticity and superior moisture resistance, making it ideal for insulation and flooring applications. Harvested cork, processed from bark strips after careful stripping and granulation, provides a versatile and eco-friendly material often used in packaging, bulletin boards, and footwear due to its lightweight and compressible nature. Selecting the right cork material depends on balancing durability, flexibility, and specific use cases, ensuring the chosen cork type meets both performance and sustainability requirements.

Bark Cork vs Harvested Cork Infographic

materialdif.com

materialdif.com