Cork granules offer better durability and cushioning compared to cork dust, making them ideal for pet bedding and habitat substrates. The larger size of cork granules enhances airflow and reduces compaction, promoting a healthier environment for pets. Cork dust, while finer and cheaper, tends to compact quickly and may cause respiratory issues due to airborne particles.

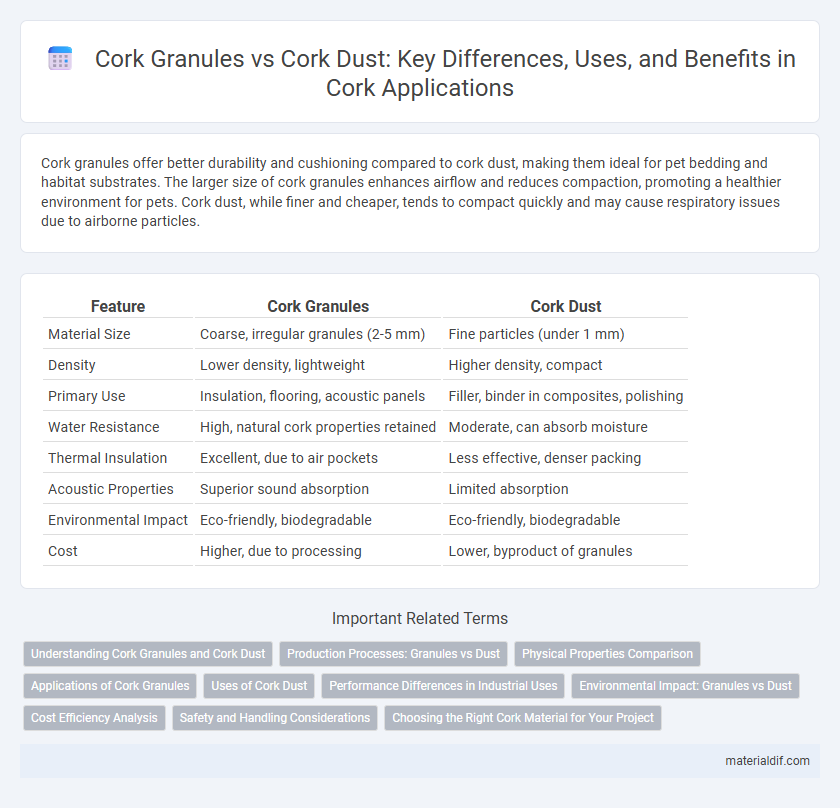

Table of Comparison

| Feature | Cork Granules | Cork Dust |

|---|---|---|

| Material Size | Coarse, irregular granules (2-5 mm) | Fine particles (under 1 mm) |

| Density | Lower density, lightweight | Higher density, compact |

| Primary Use | Insulation, flooring, acoustic panels | Filler, binder in composites, polishing |

| Water Resistance | High, natural cork properties retained | Moderate, can absorb moisture |

| Thermal Insulation | Excellent, due to air pockets | Less effective, denser packing |

| Acoustic Properties | Superior sound absorption | Limited absorption |

| Environmental Impact | Eco-friendly, biodegradable | Eco-friendly, biodegradable |

| Cost | Higher, due to processing | Lower, byproduct of granules |

Understanding Cork Granules and Cork Dust

Cork granules consist of small, uniform particles harvested from the bark of cork oak trees, offering superior durability and insulation properties compared to cork dust. Cork dust, made up of finer, powder-like fragments, is often a byproduct of cork processing with limited structural integrity and thermal resistance. Understanding the textural and compositional differences between cork granules and cork dust is essential for selecting appropriate materials in construction, flooring, and insulation applications.

Production Processes: Granules vs Dust

Cork granules are produced by grinding cork bark into uniform, coarse particles through controlled mechanical processes that preserve the material's structural integrity, making them ideal for insulation and flooring applications. Cork dust results from further milling and finer grinding of granules, yielding a powdery substance commonly used in adhesives and as a filler in composite materials. The distinct production methods influence the physical properties and suitability of cork granules and dust for various industrial uses.

Physical Properties Comparison

Cork granules have a coarser texture and higher density compared to cork dust, resulting in greater durability and structural integrity for applications like insulation and flooring. Cork dust, being finer and lighter, offers superior thermal insulation but lower mechanical strength, making it ideal for fillers and biodegradable composites. The larger particle size of cork granules enhances compressive resistance, whereas cork dust provides increased surface area for bonding in adhesives and coatings.

Applications of Cork Granules

Cork granules are widely used in applications such as flooring insulation, sports surfaces, and acoustic panels due to their durability and thermal properties. Unlike cork dust, which is primarily a byproduct with limited uses, cork granules provide better structural integrity and moisture resistance. These granules also serve as fillers in composites and are popular in horticulture for soil aeration and moisture retention.

Uses of Cork Dust

Cork dust is widely used in horticulture as a natural soil conditioner and mulch due to its excellent water retention and aeration properties. It also serves as a key component in the manufacture of agglomerated cork products, providing enhanced flexibility and resilience. Unlike cork granules, cork dust is preferred for its finer texture in applications such as insulation, soundproofing, and adhesive fillers.

Performance Differences in Industrial Uses

Cork granules offer superior performance in industrial applications due to their uniform size and enhanced cushioning properties, making them ideal for vibration damping and insulation. Cork dust, with its finer particles, provides less structural integrity but excels in filling gaps and acting as an absorbent material. Industrial processes benefit from granules when durability and mechanical strength are critical, while cork dust is preferred for applications requiring flexibility and moisture absorption.

Environmental Impact: Granules vs Dust

Cork granules have a lower environmental impact compared to cork dust due to their larger particle size, which results in less airborne dispersion and reduced respiratory hazards during production. The use of granules supports sustainable recycling processes by enabling efficient reuse in products like flooring and insulation, minimizing waste accumulation. In contrast, cork dust, often considered a byproduct, poses challenges in disposal and can contribute to air pollution and occupational health risks if not properly managed.

Cost Efficiency Analysis

Cork granules offer greater cost efficiency compared to cork dust due to their higher durability and lower product loss during processing. The larger particle size of granules reduces waste and improves insulation performance, leading to long-term savings in material and energy costs. While cork dust may appear cheaper upfront, its lower density and increased dust particles result in higher handling expenses and decreased thermal efficiency.

Safety and Handling Considerations

Cork granules offer enhanced safety for handling due to their larger, more uniform particle size, reducing the risk of airborne dust inhalation compared to fine cork dust. Cork dust poses respiratory hazards and requires proper ventilation and protective equipment to prevent allergic reactions and respiratory irritation. Proper storage and handling protocols are essential for both materials to minimize dust generation and ensure workplace safety.

Choosing the Right Cork Material for Your Project

Cork granules offer superior durability and insulation properties compared to cork dust, making them ideal for construction and flooring applications where strength and thermal regulation are essential. Cork dust, being finer and more pliable, is best suited for filler materials, polishing agents, and lightweight composites in artisanal projects. Selecting the appropriate cork material depends on the specific structural demands and aesthetic requirements of your project in Cork-based developments.

cork granules vs cork dust Infographic

materialdif.com

materialdif.com