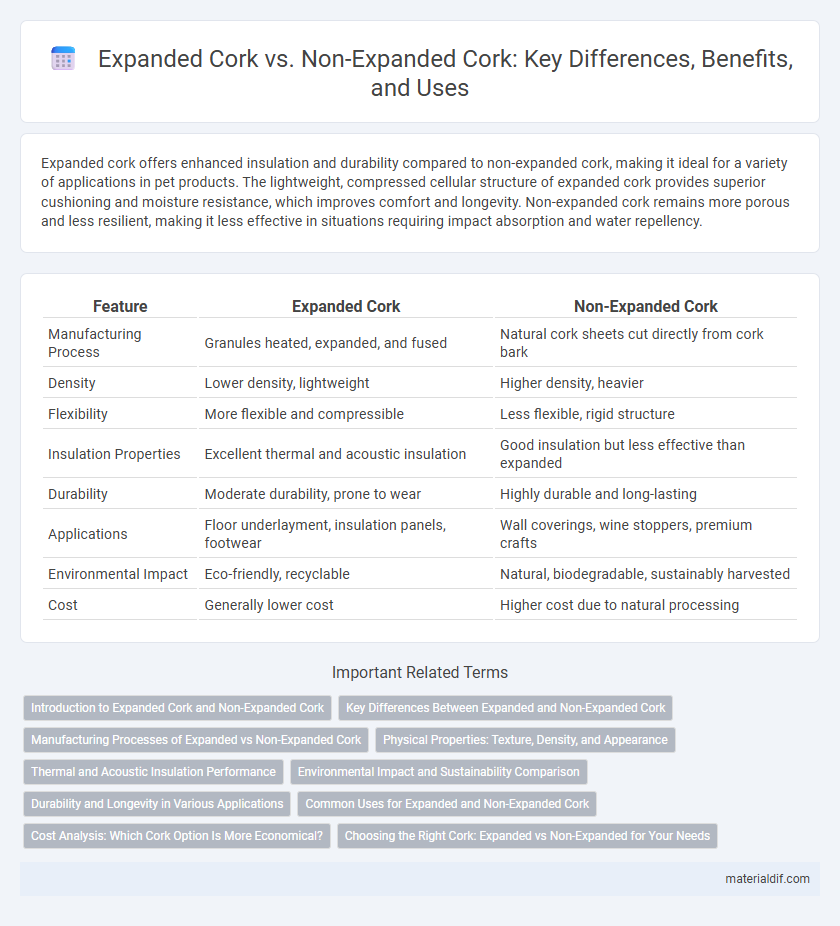

Expanded cork offers enhanced insulation and durability compared to non-expanded cork, making it ideal for a variety of applications in pet products. The lightweight, compressed cellular structure of expanded cork provides superior cushioning and moisture resistance, which improves comfort and longevity. Non-expanded cork remains more porous and less resilient, making it less effective in situations requiring impact absorption and water repellency.

Table of Comparison

| Feature | Expanded Cork | Non-Expanded Cork |

|---|---|---|

| Manufacturing Process | Granules heated, expanded, and fused | Natural cork sheets cut directly from cork bark |

| Density | Lower density, lightweight | Higher density, heavier |

| Flexibility | More flexible and compressible | Less flexible, rigid structure |

| Insulation Properties | Excellent thermal and acoustic insulation | Good insulation but less effective than expanded |

| Durability | Moderate durability, prone to wear | Highly durable and long-lasting |

| Applications | Floor underlayment, insulation panels, footwear | Wall coverings, wine stoppers, premium crafts |

| Environmental Impact | Eco-friendly, recyclable | Natural, biodegradable, sustainably harvested |

| Cost | Generally lower cost | Higher cost due to natural processing |

Introduction to Expanded Cork and Non-Expanded Cork

Expanded cork, also known as aglomerated cork, is produced by heating natural cork granules to create a lightweight, elastic material widely used in insulation, flooring, and decorative applications. Non-expanded cork retains its natural cellular structure, offering superior breathability and moisture resistance, making it ideal for products like wine stoppers and acoustic panels. Both types leverage cork's sustainability and resilience, but expanded cork's engineered form enhances versatility in industrial and architectural uses.

Key Differences Between Expanded and Non-Expanded Cork

Expanded cork undergoes a heating process that causes the cork granules to expand and bind together, creating a lightweight, flexible, and insulating material. Non-expanded cork, also known as natural cork, retains its original granule size and density, offering a firmer texture with less elasticity and lower thermal insulation properties. Key differences include expanded cork's enhanced compressibility and superior thermal and acoustic insulation compared to the more rigid and less insulating non-expanded cork.

Manufacturing Processes of Expanded vs Non-Expanded Cork

Expanded cork undergoes a thermal treatment where raw cork granules are heated to around 300degC, causing them to expand and bind naturally without adhesives, resulting in lightweight and flexible panels. Non-expanded cork is produced by mechanically compressing cork granules with synthetic or natural binders, creating denser, less elastic sheets or blocks. The key manufacturing difference lies in the use of heat expansion in expanded cork versus binder-based compression in non-expanded cork.

Physical Properties: Texture, Density, and Appearance

Expanded cork exhibits a lighter density and more uniform texture compared to non-expanded cork, which retains a denser and more irregular structure due to the absence of thermal treatment. The physical appearance of expanded cork is characterized by a finer, sponge-like surface with consistent porosity, whereas non-expanded cork maintains a natural, rough texture with visible grain patterns. These differences in texture, density, and appearance influence suitability for applications requiring lightweight insulation or structural durability.

Thermal and Acoustic Insulation Performance

Expanded cork exhibits superior thermal insulation performance due to its closed-cell structure, which minimizes heat transfer and enhances energy efficiency in buildings. In acoustic insulation, expanded cork effectively absorbs and dampens sound waves, reducing noise pollution in residential and commercial spaces. Non-expanded cork, while offering moderate insulation properties, lacks the enhanced density and uniformity that contribute to the improved thermal and acoustic performance found in expanded cork products.

Environmental Impact and Sustainability Comparison

Expanded cork, produced through a natural heat expansion process without chemical additives, offers superior environmental benefits compared to non-expanded cork by utilizing cork waste and minimizing resource extraction. It promotes sustainability by enhancing cork oak forest preservation, reducing carbon footprints, and supporting biodiversity due to its renewable, biodegradable, and recyclable nature. Non-expanded cork, while still sustainable, often involves more raw material consumption and limited reuse potential, making expanded cork a more eco-friendly choice in construction and insulation industries.

Durability and Longevity in Various Applications

Expanded cork offers superior durability and longevity compared to non-expanded cork due to its enhanced cellular structure, which provides greater resistance to moisture, compression, and wear. Non-expanded cork tends to degrade faster under environmental stress, limiting its lifespan in applications like flooring, insulation, and sealing. The expanded form's resilience makes it ideal for long-term use in construction and industrial products where sustained performance is critical.

Common Uses for Expanded and Non-Expanded Cork

Expanded cork, known for its lightweight and insulating properties, is commonly used in thermal and acoustic insulation, floor underlays, and gaskets. Non-expanded cork, with its natural density and durability, is primarily utilized in wine stoppers, bulletin boards, and flooring tiles. Both types serve distinct purposes in construction, packaging, and consumer goods due to their unique physical characteristics.

Cost Analysis: Which Cork Option Is More Economical?

Expanded cork generally incurs higher production costs due to the heating and expansion processes involved, resulting in a price premium compared to non-expanded cork. Non-expanded cork, harvested directly from the cork oak bark without additional processing, offers a more economical choice for budget-conscious applications. Evaluating lifecycle costs, expanded cork may justify its higher price through enhanced insulation and durability, potentially reducing long-term expenses.

Choosing the Right Cork: Expanded vs Non-Expanded for Your Needs

Expanded cork offers superior insulation, enhanced durability, and greater flexibility, making it ideal for construction and thermal applications. Non-expanded cork is denser and retains more natural moisture, often preferred for wine stoppers and crafts requiring a firmer texture. Selecting the right cork depends on balancing insulation needs, moisture resistance, and structural requirements specific to the project.

Expanded cork vs Non-expanded cork Infographic

materialdif.com

materialdif.com