Cork-rubber composites offer enhanced durability and flexibility compared to pure cork, making them ideal for applications requiring both resilience and lightweight properties. These composites maintain cork's natural insulation and shock absorption while improving resistance to wear and moisture. As a result, cork-rubber materials are widely used in flooring, gaskets, and footwear, combining the eco-friendly benefits of cork with the strength of rubber.

Table of Comparison

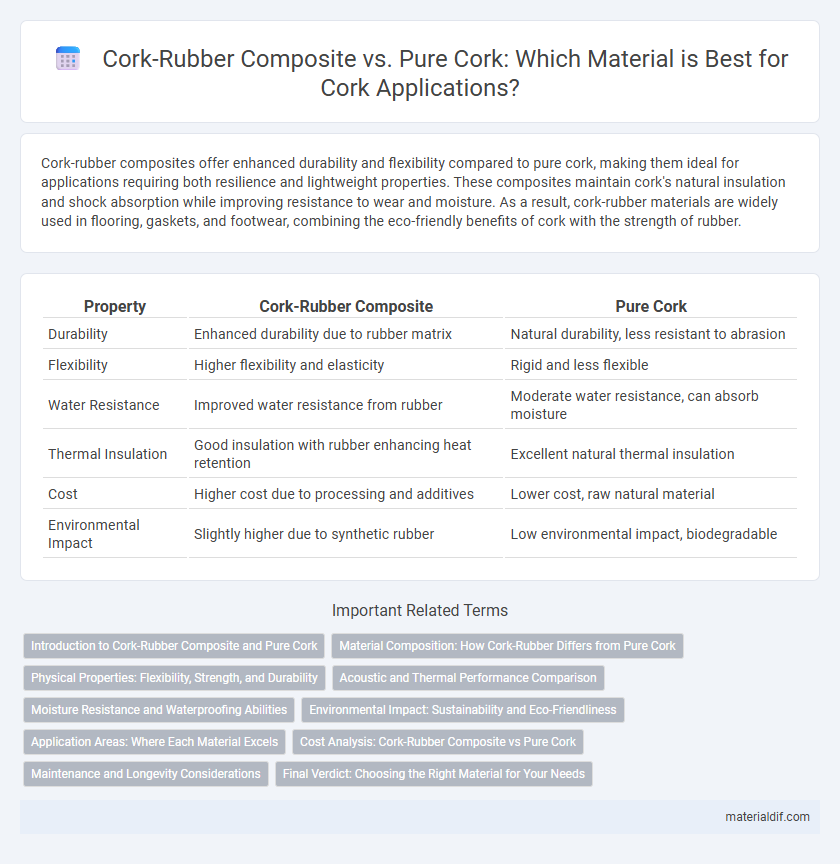

| Property | Cork-Rubber Composite | Pure Cork |

|---|---|---|

| Durability | Enhanced durability due to rubber matrix | Natural durability, less resistant to abrasion |

| Flexibility | Higher flexibility and elasticity | Rigid and less flexible |

| Water Resistance | Improved water resistance from rubber | Moderate water resistance, can absorb moisture |

| Thermal Insulation | Good insulation with rubber enhancing heat retention | Excellent natural thermal insulation |

| Cost | Higher cost due to processing and additives | Lower cost, raw natural material |

| Environmental Impact | Slightly higher due to synthetic rubber | Low environmental impact, biodegradable |

Introduction to Cork-Rubber Composite and Pure Cork

Cork-rubber composites combine natural cork granules with synthetic rubber, enhancing flexibility, durability, and impact resistance compared to pure cork, which consists solely of natural cork material harvested from cork oak trees. Pure cork offers excellent thermal and acoustic insulation due to its cellular structure but lacks the mechanical strength and elasticity that cork-rubber composites provide. These composites are widely used in industries requiring lightweight, resilient materials, such as automotive and footwear, while pure cork remains popular for sustainable packaging and eco-friendly flooring solutions.

Material Composition: How Cork-Rubber Differs from Pure Cork

Cork-rubber composites combine natural cork granules with synthetic rubber binders, enhancing flexibility and durability compared to pure cork, which is composed solely of cellular plant material from cork oak bark. The inclusion of rubber improves impact resistance and elasticity, making cork-rubber composites suitable for applications requiring cushioning and resilience, unlike pure cork's lightweight, compressible, and insulating properties. This hybrid material benefits industries such as footwear, automotive, and sports equipment by offering a balance between natural sustainability and engineered performance.

Physical Properties: Flexibility, Strength, and Durability

Cork-rubber composites exhibit enhanced flexibility compared to pure cork, making them suitable for applications requiring repeated bending and compression. The incorporation of rubber significantly increases tensile strength and impact resistance, improving overall durability against mechanical stress. Pure cork maintains excellent natural compressibility and resilience but tends to be less resistant to wear and tear over extended use than cork-rubber blends.

Acoustic and Thermal Performance Comparison

Cork-rubber composites exhibit enhanced acoustic insulation compared to pure cork, significantly reducing airborne noise transmission due to rubber's superior damping properties. Thermal performance in cork-rubber composites also improves, offering better heat resistance and stability through the synergistic effect of rubber's elasticity and cork's natural insulating capabilities. These composites combine cork's low thermal conductivity with rubber's flexibility, making them ideal for applications requiring both soundproofing and thermal regulation.

Moisture Resistance and Waterproofing Abilities

Cork-rubber composites exhibit superior moisture resistance compared to pure cork due to the rubber matrix's natural water-repellent properties, reducing water absorption significantly. Pure cork, though inherently water-resistant thanks to its cellular structure, tends to absorb more moisture over time when exposed to continuous wet conditions. The enhanced waterproofing abilities of cork-rubber composites make them ideal for applications where prolonged water exposure is expected, such as in flooring and insulation materials.

Environmental Impact: Sustainability and Eco-Friendliness

Cork-rubber composites blend natural cork with synthetic rubber, enhancing durability while maintaining significant eco-friendly properties, as cork is renewable and biodegradable. Pure cork, harvested from the bark of cork oak trees without harming them, offers superior sustainability due to its carbon sequestration and low environmental footprint. Using cork-rubber composites reduces reliance on fully synthetic materials, thus lowering overall environmental impact through increased recyclability and reduced resource depletion.

Application Areas: Where Each Material Excels

Cork-rubber composites excel in applications requiring enhanced durability and elasticity, such as automotive gaskets, flooring underlays, and vibration dampening pads, where flexibility and resilience are critical. Pure cork is ideal for insulation, wine stoppers, and acoustic panels due to its natural compressibility, thermal resistance, and sound absorption properties. Both materials serve distinct roles, with composites favored in mechanical and industrial contexts, while pure cork remains preferred in eco-friendly construction and packaging industries.

Cost Analysis: Cork-Rubber Composite vs Pure Cork

Cork-rubber composites offer a cost-effective alternative to pure cork due to lower raw material expenses and enhanced durability, reducing maintenance and replacement costs. Pure cork typically incurs higher production costs, attributed to the harvesting process and limited supply, which affects market pricing. The composite's blend optimizes performance while enabling scalable manufacturing, making it a more economical choice for large-scale applications.

Maintenance and Longevity Considerations

Cork-rubber composite offers enhanced durability and resistance to wear compared to pure cork, making it a low-maintenance option suitable for high-traffic areas. While pure cork requires regular sealing to prevent moisture damage and maintain its appearance, cork-rubber composites inherently resist water and reduce the frequency of upkeep. The longevity of cork-rubber composite flooring surpasses pure cork by minimizing cracking and abrasion, resulting in extended service life with minimal maintenance efforts.

Final Verdict: Choosing the Right Material for Your Needs

Cork-rubber composite offers enhanced durability and flexibility compared to pure cork, making it ideal for applications requiring resilience and long-term wear. Pure cork provides natural insulation, lightweight properties, and eco-friendliness, suitable for sustainable projects and design aesthetics. Your choice depends on balancing performance needs with environmental considerations, ensuring optimal functionality and sustainability in Cork-based materials.

Cork-rubber composite vs pure cork Infographic

materialdif.com

materialdif.com