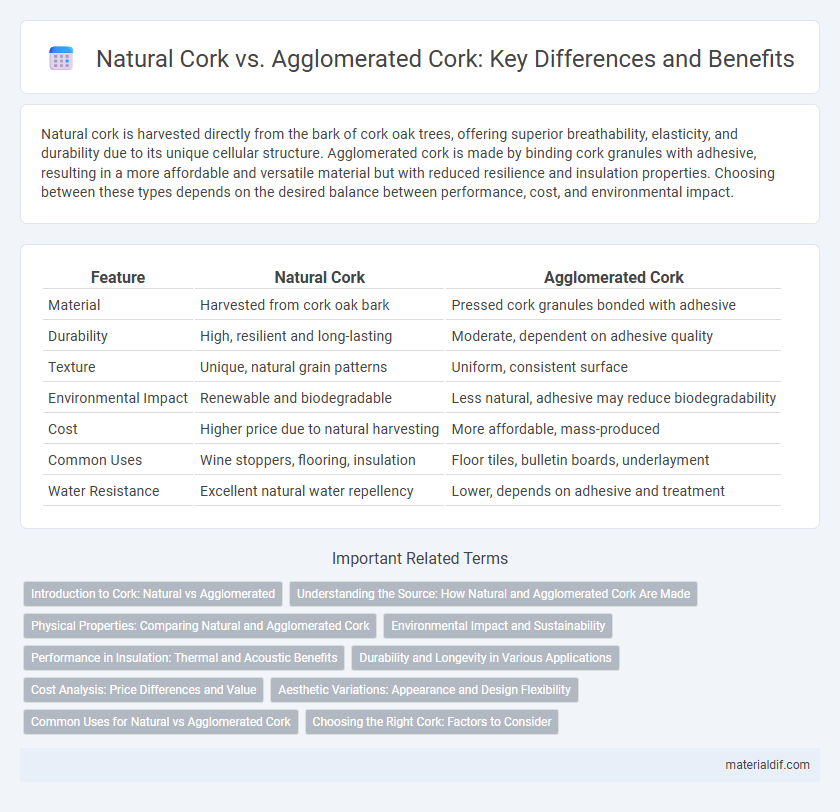

Natural cork is harvested directly from the bark of cork oak trees, offering superior breathability, elasticity, and durability due to its unique cellular structure. Agglomerated cork is made by binding cork granules with adhesive, resulting in a more affordable and versatile material but with reduced resilience and insulation properties. Choosing between these types depends on the desired balance between performance, cost, and environmental impact.

Table of Comparison

| Feature | Natural Cork | Agglomerated Cork |

|---|---|---|

| Material | Harvested from cork oak bark | Pressed cork granules bonded with adhesive |

| Durability | High, resilient and long-lasting | Moderate, dependent on adhesive quality |

| Texture | Unique, natural grain patterns | Uniform, consistent surface |

| Environmental Impact | Renewable and biodegradable | Less natural, adhesive may reduce biodegradability |

| Cost | Higher price due to natural harvesting | More affordable, mass-produced |

| Common Uses | Wine stoppers, flooring, insulation | Floor tiles, bulletin boards, underlayment |

| Water Resistance | Excellent natural water repellency | Lower, depends on adhesive and treatment |

Introduction to Cork: Natural vs Agglomerated

Natural cork is harvested directly from the bark of the cork oak tree, offering superior elasticity, impermeability, and durability ideal for wine stoppers and insulation. Agglomerated cork consists of granulated cork pieces bonded with adhesives, providing a cost-effective, versatile option commonly used in flooring and bulletin boards. Understanding their distinct properties highlights natural cork's premium quality and agglomerated cork's practicality in various industrial applications.

Understanding the Source: How Natural and Agglomerated Cork Are Made

Natural cork is harvested directly from the bark of the cork oak tree (Quercus suber), involving a careful stripping process that preserves the tree's health and allows for sustainable regeneration approximately every nine years. Agglomerated cork is manufactured by binding granules of natural cork with adhesives under heat and pressure, creating a composite material with customizable density and texture for varied industrial applications. Understanding these production methods clarifies the distinctions in durability, flexibility, and environmental impact between natural and agglomerated cork products.

Physical Properties: Comparing Natural and Agglomerated Cork

Natural cork exhibits superior elasticity, compressibility, and resilience due to its cellular structure composed of suberin and lignin, enabling it to recover shape after deformation. Agglomerated cork, made from granulated cork bonded with synthetic adhesives, has lower flexibility and uniform density but offers enhanced dimensional stability and resistance to wear in engineered applications. The porous nature of natural cork provides better thermal and acoustic insulation compared to the more rigid and less porous agglomerated variant.

Environmental Impact and Sustainability

Natural cork, harvested from the bark of cork oak trees without harming the tree, offers a highly sustainable material due to its renewable nature and carbon sequestration properties. In contrast, agglomerated cork, produced by binding cork granules with synthetic adhesives, may involve lower raw material usage but often includes non-biodegradable components, impacting its environmental footprint. The sustainable harvesting cycle of natural cork forests supports biodiversity and reduces deforestation, making it a superior eco-friendly choice compared to agglomerated cork products.

Performance in Insulation: Thermal and Acoustic Benefits

Natural cork offers superior thermal insulation due to its cellular structure, which traps air and reduces heat transfer, maintaining consistent indoor temperatures. Agglomerated cork, while still providing good acoustic insulation by dampening sound vibrations, may exhibit slightly lower thermal performance because of its composite nature and glue content. Both types effectively reduce noise pollution, but natural cork's inherent density typically enhances overall soundproofing capabilities in residential and commercial applications.

Durability and Longevity in Various Applications

Natural cork offers superior durability and longevity due to its cellular structure, which provides resilience and resistance to wear in diverse applications such as flooring and insulation. Agglomerated cork, composed of cork granules bonded with adhesives, typically exhibits reduced durability and may degrade faster under heavy use or exposure to moisture. Choosing natural cork ensures extended lifespan and sustained performance, especially in environments subject to frequent mechanical stress or fluctuating conditions.

Cost Analysis: Price Differences and Value

Natural cork, harvested directly from cork oak trees, typically commands a higher price due to its superior durability, elasticity, and environmental benefits. Agglomerated cork, made from ground cork particles bonded with adhesives, offers a more affordable alternative but often lacks the resilience and aesthetic appeal of natural cork. While natural cork delivers long-term value through enhanced performance and sustainability, agglomerated cork suits budget-conscious projects requiring cost-effective solutions.

Aesthetic Variations: Appearance and Design Flexibility

Natural cork exhibits unique, irregular patterns and color variations that enhance the aesthetic appeal of flooring and wall panels, making each piece distinct. Agglomerated cork offers uniformity and consistency in appearance, allowing for greater design flexibility and easier customization in large-scale projects. This consistency in agglomerated cork enables precise color matching and seamless installation, ideal for modern, minimalist interior designs.

Common Uses for Natural vs Agglomerated Cork

Natural cork is commonly used in wine bottle stoppers, flooring, and insulation due to its superior elasticity, water resistance, and durability. Agglomerated cork, made from cork granules bonded with adhesives, is primarily utilized in bulletin boards, underlayment, and craft materials where cost-effectiveness and uniformity are prioritized. Both types leverage cork's lightweight and thermal properties, but natural cork remains the preferred choice for applications requiring higher performance and aesthetic quality.

Choosing the Right Cork: Factors to Consider

Natural cork offers unmatched durability, breathability, and a unique cellular structure that enhances insulation and resilience, making it ideal for high-end flooring and wine stoppers. Agglomerated cork, composed of compressed cork granules bound with adhesives, provides cost-effective versatility and uniformity but may compromise on elasticity and longevity. When choosing the right cork, factors such as application demands, environmental impact, budget constraints, and performance requirements should guide the decision toward either premium natural cork or economical agglomerated cork.

natural cork vs agglomerated cork Infographic

materialdif.com

materialdif.com