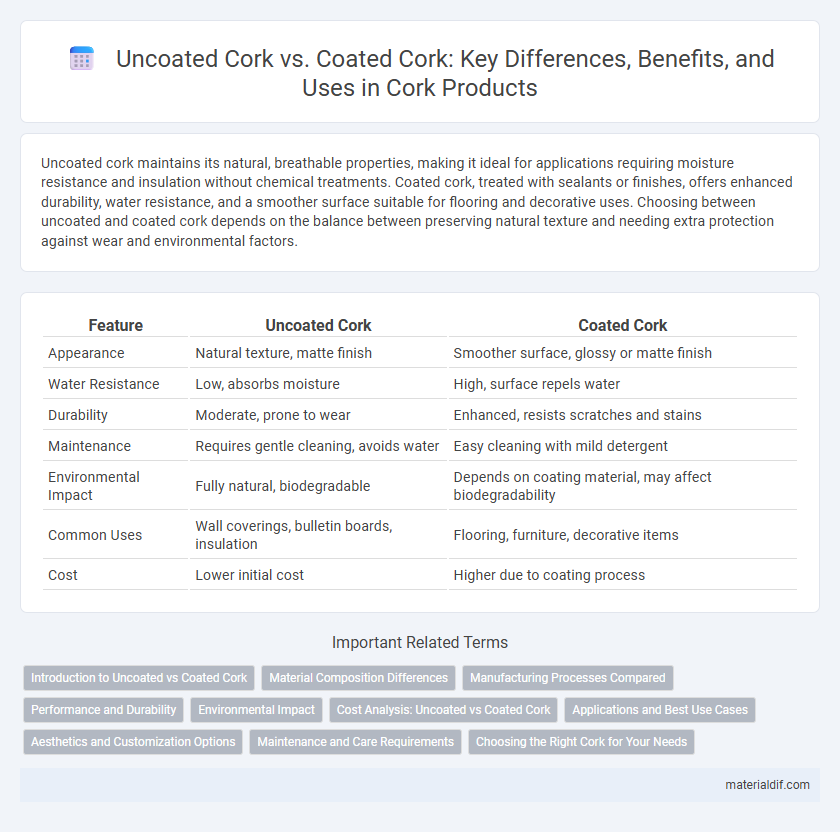

Uncoated cork maintains its natural, breathable properties, making it ideal for applications requiring moisture resistance and insulation without chemical treatments. Coated cork, treated with sealants or finishes, offers enhanced durability, water resistance, and a smoother surface suitable for flooring and decorative uses. Choosing between uncoated and coated cork depends on the balance between preserving natural texture and needing extra protection against wear and environmental factors.

Table of Comparison

| Feature | Uncoated Cork | Coated Cork |

|---|---|---|

| Appearance | Natural texture, matte finish | Smoother surface, glossy or matte finish |

| Water Resistance | Low, absorbs moisture | High, surface repels water |

| Durability | Moderate, prone to wear | Enhanced, resists scratches and stains |

| Maintenance | Requires gentle cleaning, avoids water | Easy cleaning with mild detergent |

| Environmental Impact | Fully natural, biodegradable | Depends on coating material, may affect biodegradability |

| Common Uses | Wall coverings, bulletin boards, insulation | Flooring, furniture, decorative items |

| Cost | Lower initial cost | Higher due to coating process |

Introduction to Uncoated vs Coated Cork

Uncoated cork retains its natural porous texture, providing enhanced breathability and a more authentic, tactile experience ideal for eco-friendly products and sustainable design. Coated cork features a protective layer, which increases durability, water resistance, and ease of cleaning, making it suitable for high-traffic applications and moisture-prone environments. Choosing between uncoated and coated cork depends on the specific performance requirements and aesthetic preferences for each project.

Material Composition Differences

Uncoated cork consists of natural cork material with a porous, breathable structure, preserving its original texture and cellular makeup. Coated cork features a protective layer such as polyurethane or resin, which alters the surface by sealing pores and enhancing durability against moisture and wear. The coating modifies the cork's natural breathability and flexibility, impacting its performance in applications requiring cushioning or insulation.

Manufacturing Processes Compared

Uncoated cork undergoes a minimal processing method involving scraping, boiling, and drying, preserving its natural texture and breathability without any added finishes. Coated cork includes additional steps such as applying polyurethane, acrylic, or varnish coatings to enhance durability, water resistance, and appearance. These coatings require curing processes that increase production time and cost but result in a product suited for high-traffic areas and moisture-prone environments.

Performance and Durability

Uncoated cork offers natural breathability and moisture resistance, making it ideal for applications requiring flexibility and eco-friendliness. Coated cork enhances durability by providing a protective layer against wear, water absorption, and UV damage, significantly extending the material's lifespan. Performance-wise, coated cork delivers superior resistance to abrasion and environmental stress, though it may sacrifice some of the natural texture and breathability found in uncoated variants.

Environmental Impact

Uncoated cork offers a lower environmental impact as it undergoes minimal processing, preserving its natural biodegradability and maintaining carbon sequestration properties. Coated cork products often involve chemical treatments or synthetic finishes that can reduce recyclability and introduce pollutants during manufacturing. Choosing uncoated cork supports sustainable forestry practices and reduces waste in cork product life cycles.

Cost Analysis: Uncoated vs Coated Cork

Uncoated cork generally incurs lower initial costs due to minimal processing, making it a cost-effective option for budget-conscious projects. Coated cork, while more expensive upfront, offers enhanced durability and resistance to moisture and wear, potentially reducing long-term maintenance expenses. Evaluating the total cost of ownership reveals that coated cork may provide better value in applications requiring extended longevity and protection.

Applications and Best Use Cases

Uncoated cork offers superior breathability and natural texture, making it ideal for applications such as wine bottle stoppers, bulletin boards, and acoustic panels where moisture regulation and tactile feel are essential. Coated cork, enhanced with polyurethane or other sealants, provides increased durability and water resistance, suited for flooring, countertops, and outdoor furniture exposed to wear and environmental factors. Selecting uncoated cork benefits industries prioritizing eco-friendly and natural aesthetics, while coated cork best serves areas requiring prolonged surface protection and ease of maintenance.

Aesthetics and Customization Options

Uncoated cork offers a natural, rustic appearance showcasing the material's unique texture and grain, ideal for projects emphasizing organic aesthetics. Coated cork provides a smooth, polished finish with enhanced color vibrancy and protection, allowing for a wider range of customizable designs, including printed patterns or vibrant hues. Customization options expand with coated cork due to its ability to accept various finishes, making it suitable for both modern and traditional design preferences.

Maintenance and Care Requirements

Uncoated cork requires regular sealing with a water-based finish to prevent moisture absorption and staining, making maintenance more frequent but preserving its natural texture. Coated cork offers enhanced protection against spills and scratches, reducing the need for sealing and simplifying cleaning routines with just a damp cloth. Both types benefit from avoiding harsh chemicals and direct sunlight to extend durability and appearance.

Choosing the Right Cork for Your Needs

Uncoated cork offers natural breathability and a softer texture, making it ideal for applications where grip and environmental sustainability are priorities. Coated cork features a protective layer that enhances durability, water resistance, and ease of cleaning, suited for high-traffic or moisture-prone environments. Selecting the right cork depends on balancing factors like wear resistance, aesthetics, and maintenance requirements specific to your project.

uncoated cork vs coated cork Infographic

materialdif.com

materialdif.com