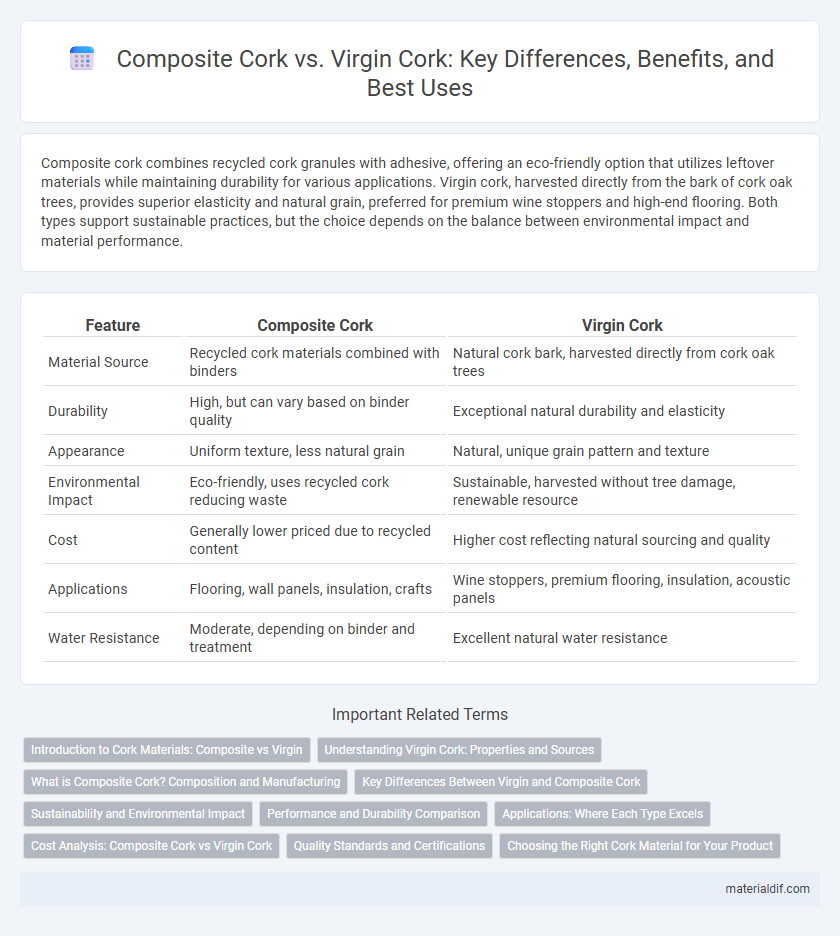

Composite cork combines recycled cork granules with adhesive, offering an eco-friendly option that utilizes leftover materials while maintaining durability for various applications. Virgin cork, harvested directly from the bark of cork oak trees, provides superior elasticity and natural grain, preferred for premium wine stoppers and high-end flooring. Both types support sustainable practices, but the choice depends on the balance between environmental impact and material performance.

Table of Comparison

| Feature | Composite Cork | Virgin Cork |

|---|---|---|

| Material Source | Recycled cork materials combined with binders | Natural cork bark, harvested directly from cork oak trees |

| Durability | High, but can vary based on binder quality | Exceptional natural durability and elasticity |

| Appearance | Uniform texture, less natural grain | Natural, unique grain pattern and texture |

| Environmental Impact | Eco-friendly, uses recycled cork reducing waste | Sustainable, harvested without tree damage, renewable resource |

| Cost | Generally lower priced due to recycled content | Higher cost reflecting natural sourcing and quality |

| Applications | Flooring, wall panels, insulation, crafts | Wine stoppers, premium flooring, insulation, acoustic panels |

| Water Resistance | Moderate, depending on binder and treatment | Excellent natural water resistance |

Introduction to Cork Materials: Composite vs Virgin

Composite cork consists of reclaimed cork granules bonded with adhesives, offering a sustainable and cost-effective alternative to virgin cork, which is harvested directly from cork oak trees. Virgin cork retains the natural cellular structure, providing superior elasticity, durability, and water resistance compared to composite cork. Both materials are widely used in flooring, insulation, and wine stoppers, with selection depending on the balance between performance requirements and environmental considerations.

Understanding Virgin Cork: Properties and Sources

Virgin cork is harvested directly from the bark of the cork oak tree, ensuring natural resilience, elasticity, and superior sealing properties essential for premium wine stoppers. This cork type offers uniform cellular structure and higher durability compared to composite cork, which is made from ground cork particles bonded with adhesives. Primary sources of virgin cork include the Mediterranean regions of Portugal, Spain, and Morocco, where sustainable debarking practices allow for repeated harvests every 9 to 12 years.

What is Composite Cork? Composition and Manufacturing

Composite cork is an engineered material made by binding granulated cork particles with resins or adhesives, creating a versatile alternative to virgin cork. Its composition typically includes recycled cork fragments mixed with synthetic binders, enhancing durability and cost-effectiveness while maintaining key cork properties such as elasticity and impermeability. The manufacturing process involves shredding cork bark, granulating it into small particles, mixing with binding agents, molding under heat and pressure, and curing to form uniform sheets or blocks suitable for flooring, insulation, or bulletin boards.

Key Differences Between Virgin and Composite Cork

Virgin cork is harvested directly from the cork oak tree, maintaining its natural cellular structure, which provides superior elasticity, durability, and breathability, essential for high-quality wine stoppers and flooring. Composite cork, made from recycled cork granules bonded with adhesives, offers a more sustainable and cost-effective option but lacks the same resilience, texture, and sealing properties as virgin cork. Key differences include virgin cork's natural, intact fibers versus composite cork's processed granules, impacting performance in insulation, cushioning, and longevity applications.

Sustainability and Environmental Impact

Composite cork, made from granulated cork particles bonded with adhesives, utilizes cork waste effectively, reducing material waste and promoting circular sustainability. Virgin cork is harvested directly from cork oak trees without damaging them, supporting ecological balance and carbon sequestration through tree preservation. Both materials contribute to environmental conservation, but composite cork maximizes resource efficiency by repurposing leftover cork, while virgin cork ensures natural bark regeneration and biodiversity maintenance.

Performance and Durability Comparison

Composite cork, made from agglomerated cork granules bonded with natural or synthetic adhesives, offers enhanced durability and consistent performance under varying environmental conditions compared to virgin cork. Virgin cork, harvested directly from cork oak bark, provides superior elasticity and breathability but tends to be less resistant to wear and moisture over time. Performance tests reveal composite cork maintains structural integrity longer in high-traffic applications, while virgin cork excels in applications where natural resilience and sensory qualities are prioritized.

Applications: Where Each Type Excels

Composite cork excels in applications requiring cost-effective, sustainable solutions such as flooring underlayment, wall panels, and insulation due to its use of recycled cork granules. Virgin cork, harvested directly from cork oak bark, is preferred for premium uses like high-quality wine stoppers, luxury flooring, and acoustic panels because of its superior elasticity and durability. Industries prioritize composite cork for environmental benefits and versatility, while virgin cork dominates in sectors demanding top-grade material performance.

Cost Analysis: Composite Cork vs Virgin Cork

Composite cork offers a cost-effective alternative to virgin cork, as it is manufactured from reclaimed cork granules, significantly reducing production expenses. Virgin cork, harvested directly from cork oak trees, incurs higher costs due to sustainable harvesting methods and labor-intensive processes. While virgin cork tends to provide superior durability and natural aesthetics, composite cork is preferred for budget-conscious projects demanding functional performance.

Quality Standards and Certifications

Composite cork, often produced from leftover cork granules bonded with synthetic resins, generally meets standard quality certifications such as ISO 9001 but may not always achieve the higher natural purity standards of virgin cork. Virgin cork, harvested directly from cork oak trees without processing or mixing, complies with stringent certifications like FSC (Forest Stewardship Council) and PEFC (Programme for the Endorsement of Forest Certification), ensuring superior sustainability and purity. Quality standards for virgin cork emphasize durability, elasticity, and environmental responsibility, making it the preferred choice for applications demanding premium performance and ecological compliance.

Choosing the Right Cork Material for Your Product

Composite cork, made from agglomerated cork granules bonded with resin, offers cost-effectiveness and consistent performance, making it ideal for industrial applications and products requiring uniform density. Virgin cork, harvested directly from cork oak trees, provides superior elasticity, natural breathability, and premium quality, preferred for luxury products such as wine stoppers and high-end flooring. Selecting the right cork material depends on balancing budget constraints, desired durability, and product application requirements to ensure optimal functionality and customer satisfaction.

Composite Cork vs Virgin Cork Infographic

materialdif.com

materialdif.com