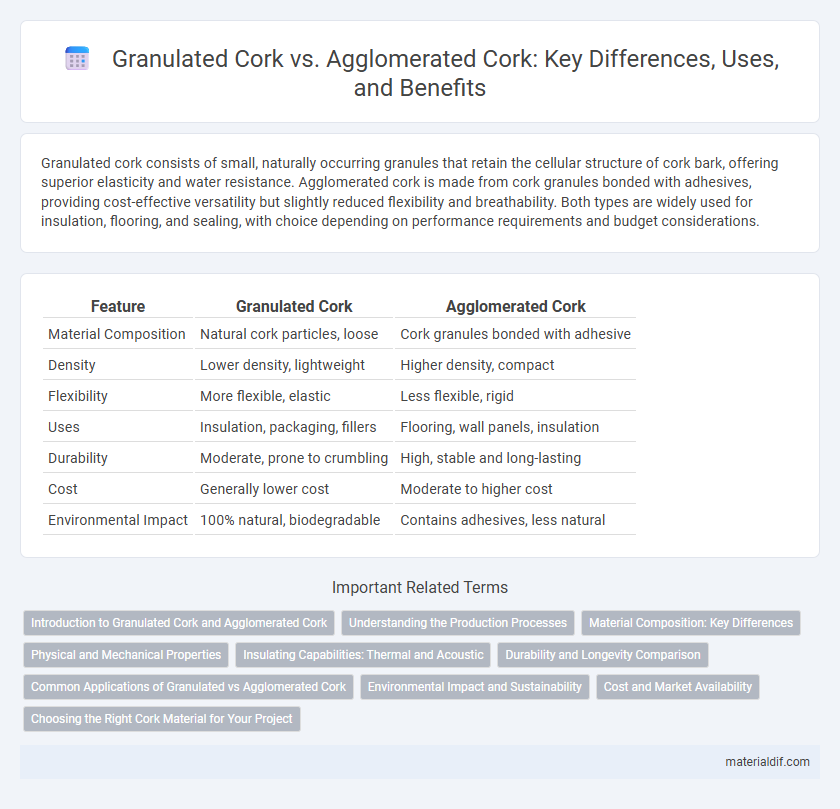

Granulated cork consists of small, naturally occurring granules that retain the cellular structure of cork bark, offering superior elasticity and water resistance. Agglomerated cork is made from cork granules bonded with adhesives, providing cost-effective versatility but slightly reduced flexibility and breathability. Both types are widely used for insulation, flooring, and sealing, with choice depending on performance requirements and budget considerations.

Table of Comparison

| Feature | Granulated Cork | Agglomerated Cork |

|---|---|---|

| Material Composition | Natural cork particles, loose | Cork granules bonded with adhesive |

| Density | Lower density, lightweight | Higher density, compact |

| Flexibility | More flexible, elastic | Less flexible, rigid |

| Uses | Insulation, packaging, fillers | Flooring, wall panels, insulation |

| Durability | Moderate, prone to crumbling | High, stable and long-lasting |

| Cost | Generally lower cost | Moderate to higher cost |

| Environmental Impact | 100% natural, biodegradable | Contains adhesives, less natural |

Introduction to Granulated Cork and Agglomerated Cork

Granulated cork consists of small, uniform particles derived from natural cork bark, offering consistent texture and superior insulation properties. Agglomerated cork is produced by binding granulated cork particles with natural or synthetic adhesives, creating a denser, versatile material used in construction and flooring. Both types maintain the renewable and lightweight qualities of cork while catering to different industrial applications based on particle size and binding methods.

Understanding the Production Processes

Granulated cork is produced by grinding natural cork bark into small granules, which are then sorted by size and quality before being used in insulation or sealing applications. Agglomerated cork is created by combining these granules with adhesives or resins and compressing them into blocks or sheets, resulting in a denser, more uniform product suitable for flooring and construction. The key difference lies in granulated cork retaining more natural texture, while agglomerated cork offers enhanced structural integrity due to its binding agents.

Material Composition: Key Differences

Granulated cork consists of small, loose pieces of cork harvested from bark, maintaining its natural cellular structure for flexibility and durability. Agglomerated cork is produced by binding cork granules with adhesives or resins, resulting in a denser material with more uniform texture and enhanced mechanical strength. The primary difference lies in granulated cork's purity and natural form versus agglomerated cork's composite structure aimed at specific industrial applications.

Physical and Mechanical Properties

Granulated cork exhibits higher elasticity and resilience due to its natural cellular structure, making it ideal for applications requiring compressibility and flexibility. Agglomerated cork, composed of cork granules bonded with adhesives, offers enhanced density and mechanical strength, providing better durability and resistance to wear. The choice between granulated and agglomerated cork depends on specific physical demands, such as impact absorption versus load-bearing capacity.

Insulating Capabilities: Thermal and Acoustic

Granulated cork offers superior thermal insulation due to its dense cellular structure that effectively reduces heat transfer, while agglomerated cork provides enhanced acoustic insulation by absorbing sound waves through its composite material made from cork granules bonded with resins. The thermal resistance (R-value) of granulated cork typically surpasses that of agglomerated cork, making it ideal for maintaining temperature stability in buildings. Agglomerated cork's porosity and varied granule sizes improve sound absorption coefficients, making it a preferred choice for noise reduction in flooring and wall applications.

Durability and Longevity Comparison

Granulated cork, derived from natural cork bark granules, offers superior durability due to its dense structure and resistance to wear and tear compared to agglomerated cork, which is bonded with adhesives and may degrade faster under stress. Agglomerated cork, while cost-effective and versatile, tends to have reduced longevity in moist or high-traffic environments because the binding agents can break down over time. For applications demanding long-term performance, granulated cork provides enhanced resilience and extended lifespan, making it ideal for flooring and insulation.

Common Applications of Granulated vs Agglomerated Cork

Granulated cork is primarily used in applications such as insulation, flooring underlayment, and sealing materials due to its fine texture and thermal properties. Agglomerated cork, consisting of compressed cork granules bonded with adhesives, is commonly applied in bulletin boards, wall tiles, and vibration dampening pads where durability and structural integrity are essential. Both types leverage cork's natural elasticity and moisture resistance but are selected based on the required density and form factor in industries like construction and interior design.

Environmental Impact and Sustainability

Granulated cork is produced by grinding the bark of cork oak trees that naturally shed their material, making it a fully renewable and biodegradable resource with minimal environmental impact. Agglomerated cork, made by bonding granulated cork particles with synthetic or natural adhesives, offers sustainable reuse of cork waste but may involve adhesives that affect recyclability. Both materials contribute to preserving cork forests, vital carbon sinks, by reducing the need to harvest new bark, supporting biodiversity and climate regulation.

Cost and Market Availability

Granulated cork typically costs more due to its finer processing and higher quality, making it less prevalent in mass-market applications compared to agglomerated cork. Agglomerated cork is widely available and more affordable, as it is made by binding cork granules with adhesive, making it suitable for insulation and flooring at a lower price point. Market demand favors agglomerated cork for cost-effective projects, while granulated cork finds niche markets requiring superior texture and durability.

Choosing the Right Cork Material for Your Project

Granulated cork offers superior density and durability, making it ideal for soundproofing and insulation in construction projects. Agglomerated cork, composed of bonded cork particles, provides cost-effective versatility and is commonly used in flooring and bulletin boards. Selecting the right cork material depends on project requirements for strength, flexibility, and budget constraints in Cork-related applications.

Granulated cork vs Agglomerated cork Infographic

materialdif.com

materialdif.com