Cork sheets offer precise thickness and uniformity, making them ideal for detailed craft projects and flooring applications requiring consistent surface properties. Cork rolls provide greater flexibility and cover larger areas more efficiently, perfect for insulation and soundproofing in walls or underlayment. Choosing between cork sheet and cork roll depends on the specific needs of your project, balancing ease of installation with durability and application type.

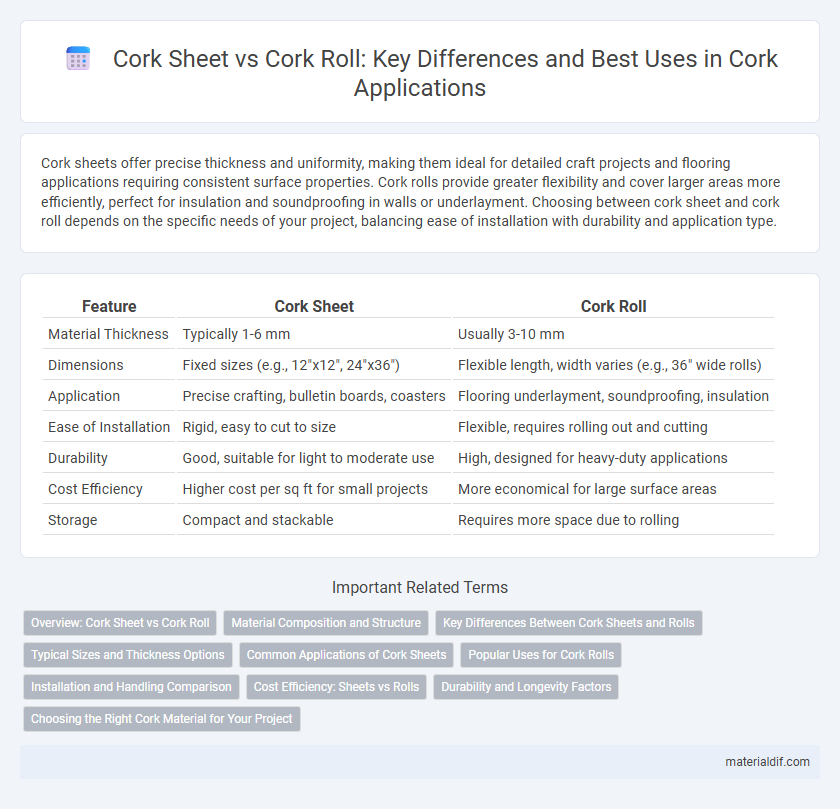

Table of Comparison

| Feature | Cork Sheet | Cork Roll |

|---|---|---|

| Material Thickness | Typically 1-6 mm | Usually 3-10 mm |

| Dimensions | Fixed sizes (e.g., 12"x12", 24"x36") | Flexible length, width varies (e.g., 36" wide rolls) |

| Application | Precise crafting, bulletin boards, coasters | Flooring underlayment, soundproofing, insulation |

| Ease of Installation | Rigid, easy to cut to size | Flexible, requires rolling out and cutting |

| Durability | Good, suitable for light to moderate use | High, designed for heavy-duty applications |

| Cost Efficiency | Higher cost per sq ft for small projects | More economical for large surface areas |

| Storage | Compact and stackable | Requires more space due to rolling |

Overview: Cork Sheet vs Cork Roll

Cork sheets offer uniform thickness and precise dimensions, making them ideal for detailed craft projects and specific insulation needs. Cork rolls provide flexibility and continuous length, suitable for larger surface applications like flooring and wall coverings. The choice between cork sheet and cork roll depends on the project's scale, precision requirements, and installation method.

Material Composition and Structure

Cork sheets consist of compressed and bonded cork granules nearly free of voids, providing a uniform thickness ideal for insulation and craft applications. Cork rolls are made by laminating thin cork layers with adhesive, offering flexibility and continuous length suitable for flooring and wall coverings. Both forms utilize natural cork bark harvested sustainably, but sheets emphasize rigidity while rolls prioritize adaptability due to their laminar structure.

Key Differences Between Cork Sheets and Rolls

Cork sheets offer uniform thickness and are ideal for precise applications like craft projects and insulation panels, while cork rolls provide flexibility and continuous length suited for large surface coverage such as flooring and wall coverings. Sheets are generally easier to handle for small-scale uses, whereas rolls accommodate extensive installations with fewer seams. The choice between cork sheets and rolls depends on project scale, application specificity, and required material adaptability.

Typical Sizes and Thickness Options

Cork sheets typically come in sizes ranging from 12x12 inches to 24x36 inches with thickness options between 1mm and 6mm, making them ideal for precise cutting and crafting projects. Cork rolls are available in widths of 12 to 48 inches and lengths up to 10 feet, offering thickness variations from 1.5mm to 10mm to accommodate larger surface applications. Both formats provide versatile solutions for insulation, flooring, and soundproofing needs, with cork rolls favored for extensive coverage and sheets preferred for detailed work.

Common Applications of Cork Sheets

Cork sheets are widely used in applications requiring precision and uniform thickness, such as gaskets, insulation panels, and bulletin boards. Their rigid structure makes them ideal for craft projects, table mats, and underlayment in flooring systems. Cork sheets also provide excellent soundproofing and vibration damping in automotive and industrial contexts.

Popular Uses for Cork Rolls

Cork rolls are popular for applications requiring large, continuous surfaces such as flooring underlayment, wall covering, and soundproofing due to their flexibility and ease of installation. Unlike cork sheets, cork rolls can cover extensive areas seamlessly, making them ideal for insulation in construction and as protective padding in sports facilities. Their versatility extends to crafts and packaging, where the roll format allows for customizable sizes and shapes.

Installation and Handling Comparison

Cork sheets offer precise dimensions and thickness consistency, making installation straightforward with minimal cutting and fitting effort, ideal for projects requiring uniformity. Cork rolls provide greater flexibility and coverage for larger areas but demand careful handling to avoid stretching or tearing during installation. Both materials are lightweight and easy to handle, yet cork sheets typically allow faster setup due to their rigidity and stable shape.

Cost Efficiency: Sheets vs Rolls

Cork sheets generally provide higher cost efficiency for small projects due to precise, waste-minimized cuts, while cork rolls offer better value for large-scale applications by covering extensive areas at a lower price per square foot. The manufacturing process of cork rolls reduces labor and material costs, making them more economical for continuous surfaces such as flooring and insulation. Evaluating project size and installation complexity is essential to determine whether sheets or rolls deliver optimal cost savings.

Durability and Longevity Factors

Cork sheets offer higher durability due to their dense composition, making them ideal for applications requiring long-term wear resistance and stability. Cork rolls provide flexibility and ease of installation, but their thinner structure can lead to faster wear and reduced longevity compared to sheets. Selecting cork sheets over rolls ensures enhanced lifespan and durability in environments subjected to heavy use or pressure.

Choosing the Right Cork Material for Your Project

Cork sheets offer uniform thickness and smooth surfaces ideal for precise applications such as bulletin boards or coasters, while cork rolls provide flexibility and larger coverage suited for flooring or insulation projects. Selecting the right cork material depends on project requirements like size, shape, and durability; sheets are easier to cut and customize, whereas rolls enable seamless installation over expansive areas. Understanding the project's functional demands ensures optimal performance and aesthetic appeal by matching specific cork formats to their intended use.

Cork Sheet vs Cork Roll Infographic

materialdif.com

materialdif.com