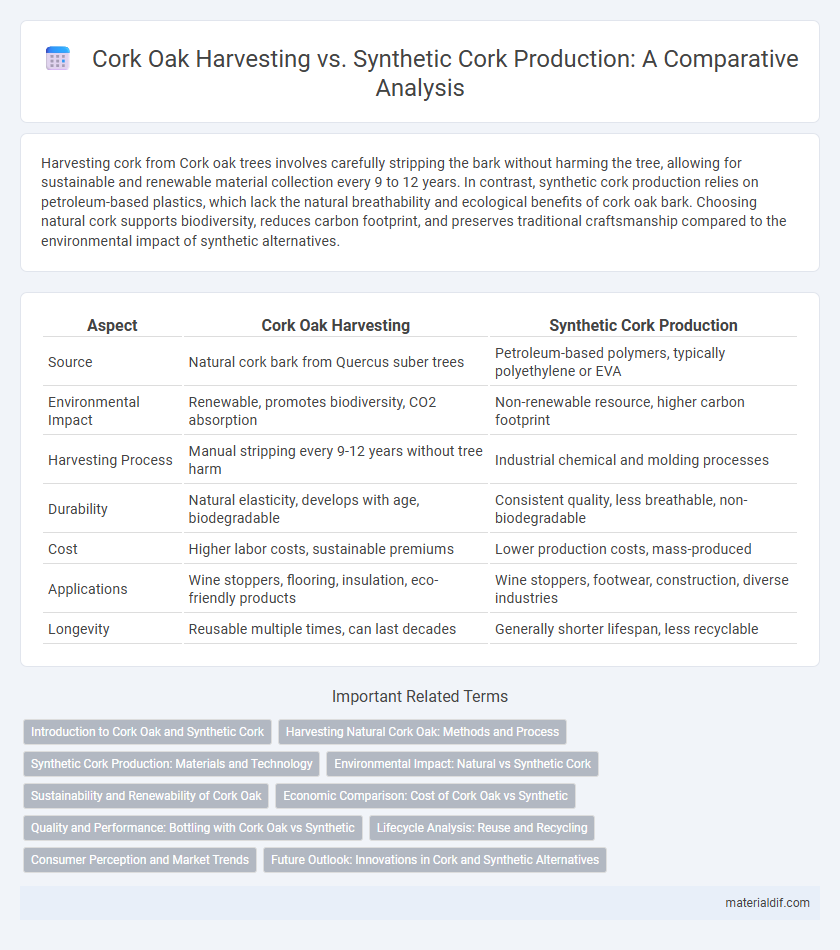

Harvesting cork from Cork oak trees involves carefully stripping the bark without harming the tree, allowing for sustainable and renewable material collection every 9 to 12 years. In contrast, synthetic cork production relies on petroleum-based plastics, which lack the natural breathability and ecological benefits of cork oak bark. Choosing natural cork supports biodiversity, reduces carbon footprint, and preserves traditional craftsmanship compared to the environmental impact of synthetic alternatives.

Table of Comparison

| Aspect | Cork Oak Harvesting | Synthetic Cork Production |

|---|---|---|

| Source | Natural cork bark from Quercus suber trees | Petroleum-based polymers, typically polyethylene or EVA |

| Environmental Impact | Renewable, promotes biodiversity, CO2 absorption | Non-renewable resource, higher carbon footprint |

| Harvesting Process | Manual stripping every 9-12 years without tree harm | Industrial chemical and molding processes |

| Durability | Natural elasticity, develops with age, biodegradable | Consistent quality, less breathable, non-biodegradable |

| Cost | Higher labor costs, sustainable premiums | Lower production costs, mass-produced |

| Applications | Wine stoppers, flooring, insulation, eco-friendly products | Wine stoppers, footwear, construction, diverse industries |

| Longevity | Reusable multiple times, can last decades | Generally shorter lifespan, less recyclable |

Introduction to Cork Oak and Synthetic Cork

Cork oak (Quercus suber) is a Mediterranean tree species primarily harvested for its bark, which regenerates every 9 to 12 years, making cork production highly sustainable and eco-friendly. Synthetic corks are manufactured using plastics or elastomers, providing consistent quality and eliminating natural variability but lacking the environmental benefits of cork oak harvesting. The natural cellular structure of cork oak delivers superior elasticity, breathability, and biodegradability compared to synthetic alternatives, influencing the wine industry's preference for traditional cork.

Harvesting Natural Cork Oak: Methods and Process

Harvesting natural cork oak involves carefully stripping the bark from mature Quercus suber trees every 9 to 12 years, ensuring the tree remains unharmed and can regenerate. Skilled workers use specialized hand axes to remove the outer bark layers without damaging the inner layer, a process that preserves the tree's health for sustainable cork production. This traditional, eco-friendly method supports biodiversity and carbon sequestration, differentiating natural cork from synthetic alternatives produced through petrochemical processes.

Synthetic Cork Production: Materials and Technology

Synthetic cork production primarily utilizes advanced polymers such as polyethylene and ethylene-vinyl acetate, engineered to mimic the compression and elasticity of natural cork. Cutting-edge injection molding and extrusion technologies enable precise control over density, texture, and permeability, ensuring consistent performance in wine sealing applications. Innovations in biocompatible and recyclable materials are driving sustainable alternatives to traditional cork, reducing reliance on cork oak harvesting while maintaining product efficacy.

Environmental Impact: Natural vs Synthetic Cork

Cork oak harvesting is a sustainable process that supports biodiversity, as trees can be stripped every 9-12 years without harm and absorb significant amounts of CO2, helping mitigate climate change. In contrast, synthetic cork production relies on petrochemicals and generates higher carbon emissions, contributing to environmental pollution and resource depletion. The renewable nature and biodegradability of natural cork make it a far more eco-friendly alternative to synthetic cork in terms of environmental impact.

Sustainability and Renewability of Cork Oak

Cork oak harvesting offers a sustainable and renewable approach by allowing the tree's bark to be stripped every 9 to 12 years without harming the tree, enabling continuous cork production for up to 200 years. This natural process supports biodiversity and carbon sequestration in cork oak forests, contrasting with synthetic cork production that relies heavily on fossil fuels and generates more waste. Cork oak landscapes thus promote ecological balance and reduce carbon footprints, highlighting the environmental advantages of natural cork over synthetic alternatives.

Economic Comparison: Cost of Cork Oak vs Synthetic

Cork oak harvesting involves higher initial labor costs due to manual stripping and sustainable forest management but benefits from long-term economic gains through renewable resource cycles and premium pricing. Synthetic cork production requires substantial capital investment in petrochemical materials and manufacturing processes, leading to consistent but potentially higher per-unit costs without environmental renewability. Overall, cork oak presents a more economically sustainable option with cost advantages linked to biodegradability and market demand for natural products.

Quality and Performance: Bottling with Cork Oak vs Synthetic

Cork oak harvesting provides natural cork stoppers renowned for their superior elasticity, breathability, and ability to age wine gracefully by allowing micro-oxygenation, which enhances flavor complexity over time. Synthetic corks, typically made from plastic polymers, offer consistent performance and eliminate risks of cork taint but generally lack the nuanced interaction with wine that natural cork provides, potentially impacting long-term aging quality. Quality-focused wineries often prefer natural cork for premium bottling to preserve authenticity and enhance the sensory profile, while synthetic corks are favored for cost efficiency and consistency in mass production.

Lifecycle Analysis: Reuse and Recycling

Cork oak harvesting promotes a sustainable lifecycle by enabling the bark to regrow every 9-12 years, supporting continuous harvest without tree felling and enhancing carbon sequestration. Reuse and recycling of natural cork stoppers contribute to significant waste reduction and energy savings, as cork can be repurposed into products like flooring and insulation. In contrast, synthetic cork production relies on petrochemical raw materials, generating higher carbon emissions and limited recycling opportunities, which negatively impact its overall environmental footprint.

Consumer Perception and Market Trends

Consumers increasingly value Cork oak harvesting for its sustainability, biodegradability, and connection to traditional craftsmanship, driving demand in premium wine closures. Synthetic cork production offers consistency and cost-effectiveness but faces skepticism regarding environmental impact and authenticity. Market trends reveal a growing preference for natural corks, fueled by eco-conscious consumers and wineries emphasizing quality and heritage.

Future Outlook: Innovations in Cork and Synthetic Alternatives

Innovations in cork harvesting emphasize sustainable practices that enhance bark regeneration and support biodiversity in Cork oak forests, ensuring long-term supply and ecological balance. Advances in synthetic cork production focus on bio-based polymers and improved sealing performance, aiming to match the environmental benefits and sensory qualities of natural cork. Future outlooks highlight hybrid solutions combining natural cork with synthetic enhancements to optimize durability, sustainability, and consumer appeal in wine closures.

Cork oak harvesting vs Synthetic cork production Infographic

materialdif.com

materialdif.com