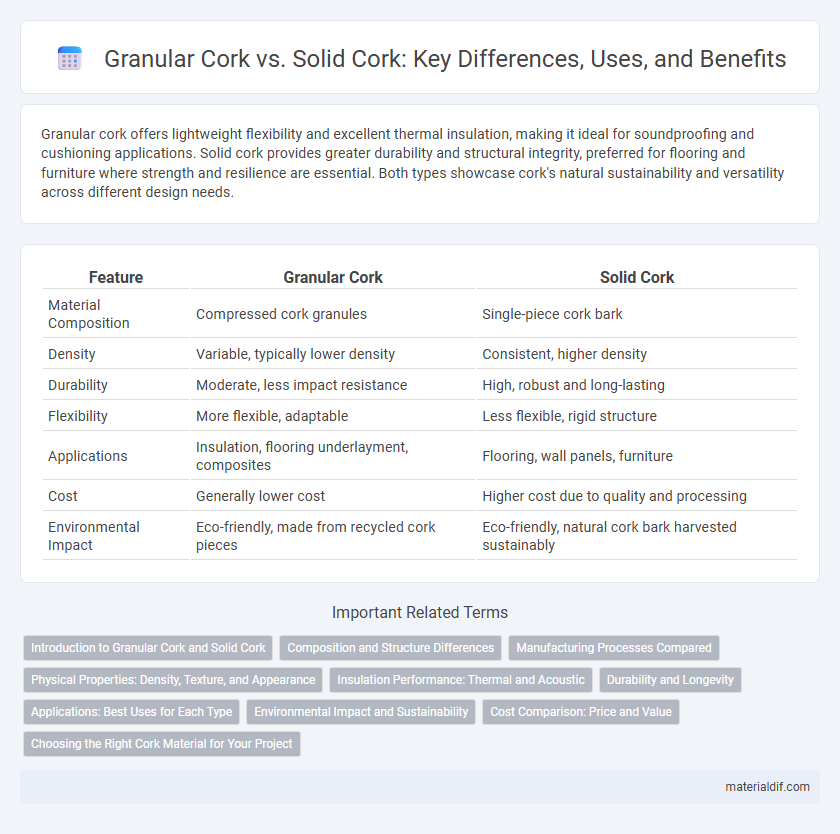

Granular cork offers lightweight flexibility and excellent thermal insulation, making it ideal for soundproofing and cushioning applications. Solid cork provides greater durability and structural integrity, preferred for flooring and furniture where strength and resilience are essential. Both types showcase cork's natural sustainability and versatility across different design needs.

Table of Comparison

| Feature | Granular Cork | Solid Cork |

|---|---|---|

| Material Composition | Compressed cork granules | Single-piece cork bark |

| Density | Variable, typically lower density | Consistent, higher density |

| Durability | Moderate, less impact resistance | High, robust and long-lasting |

| Flexibility | More flexible, adaptable | Less flexible, rigid structure |

| Applications | Insulation, flooring underlayment, composites | Flooring, wall panels, furniture |

| Cost | Generally lower cost | Higher cost due to quality and processing |

| Environmental Impact | Eco-friendly, made from recycled cork pieces | Eco-friendly, natural cork bark harvested sustainably |

Introduction to Granular Cork and Solid Cork

Granular cork consists of small, processed cork particles bonded together, offering flexibility and lightweight properties ideal for insulation and acoustic applications. Solid cork is harvested in large, uniform sheets directly from the cork oak bark, known for its natural durability and elasticity, commonly used in flooring and wine stoppers. Both types leverage cork's renewable, hypoallergenic, and moisture-resistant characteristics, but granular cork provides enhanced adaptability in composite materials.

Composition and Structure Differences

Granular cork consists of small, irregularly shaped cork particles bonded together with adhesives, resulting in a composite material with a more flexible and less uniform structure. Solid cork, by contrast, is derived from a single piece of the cork bark, offering a denser, more homogenous cellular structure that provides superior durability and natural elasticity. The composition and structural differences impact their applications, with granular cork often used for insulation and cushioning, while solid cork is preferred for flooring, stoppers, and acoustic panels.

Manufacturing Processes Compared

Granular cork is manufactured by agglomerating cork granules with binders under high pressure and heat, enabling the recycling of cork waste into uniform sheets or blocks. Solid cork is obtained by directly harvesting thick bark slabs from cork oak trees, which are then carefully shaped and sanded without adhesives or fillers, preserving the material's natural cellular structure. The manufacturing process of granular cork allows for greater material customization and cost efficiency, while solid cork offers superior durability and elasticity due to its intact natural composition.

Physical Properties: Density, Texture, and Appearance

Granular cork features a denser composition with a coarse texture, resulting from compressed cork particles that create a rugged appearance suitable for insulation and cushioning applications. Solid cork exhibits a lighter density, a smooth, uniform texture, and a natural, continuous grain pattern prized for aesthetic uses in flooring and decorative items. The physical differences between granular and solid cork directly affect their durability, flexibility, and visual appeal in various industrial and design contexts.

Insulation Performance: Thermal and Acoustic

Granular cork offers superior thermal insulation due to its ability to trap air within its irregular structure, providing excellent resistance to heat transfer. Solid cork, while denser, provides effective acoustic insulation by dampening vibrations and reducing sound transmission through its uniform cellular composition. Both materials excel in insulation, but granular cork is preferred for thermal efficiency, whereas solid cork is often chosen for enhanced acoustic performance.

Durability and Longevity

Granular cork, composed of compressed cork particles, offers enhanced flexibility but is generally less durable than solid cork, which is harvested in whole planks from the bark. Solid cork provides superior longevity due to its natural cellular structure, resisting wear, moisture, and compression more effectively over time. For applications demanding extended durability, such as flooring or insulation, solid cork remains the preferred choice because of its robust performance and natural resilience.

Applications: Best Uses for Each Type

Granular cork is ideal for applications requiring flexibility and cushioning, such as underlayment for flooring, insulation, and gaskets, due to its compressible and lightweight nature. Solid cork, with its dense and durable structure, is best suited for products like wine stoppers, flooring tiles, and bulletin boards where strength and longevity are essential. Choosing between granular and solid cork depends on the specific performance and aesthetic requirements of the project.

Environmental Impact and Sustainability

Granular cork, derived from reclaimed cork waste, promotes sustainability by minimizing resource consumption and reducing landfill waste, whereas solid cork is harvested directly from cork oak bark, requiring careful management to prevent deforestation. Both materials offer renewable and biodegradable options, but granular cork's use of recycled byproducts significantly lowers its environmental footprint. Sustainable harvesting practices and cork oak conservation remain crucial for maintaining the ecosystem benefits associated with solid cork production.

Cost Comparison: Price and Value

Granular cork typically costs less than solid cork due to its manufacturing process, which involves binding small cork particles together, offering a more economical option for insulation and flooring. Solid cork, made from a single piece of cork bark, delivers superior durability and aesthetic appeal, justifying its higher price point in premium applications. Evaluating price against long-term value, granular cork suits budget-conscious projects, while solid cork provides enhanced longevity and performance, resulting in better ROI over time.

Choosing the Right Cork Material for Your Project

Granular cork offers superior flexibility and cushioning, making it ideal for insulation, packaging, and expansion joints, whereas solid cork provides greater density and durability suited for flooring, wall coverings, and decorative applications. The choice between granular and solid cork depends on project requirements like compressibility, moisture resistance, and aesthetic appeal. Understanding the specific performance characteristics of each cork type ensures optimal material selection to enhance project longevity and functionality.

Granular Cork vs Solid Cork Infographic

materialdif.com

materialdif.com