Cork sheets offer natural durability, water resistance, and excellent insulating properties, making them ideal for flooring, bulletin boards, and soundproofing applications. Foam sheets provide superior cushioning, flexibility, and lightweight characteristics, often used in packaging, insulation, and craft projects. Choosing between cork and foam sheets depends on the specific need for resilience, environmental benefits, or softness in your project.

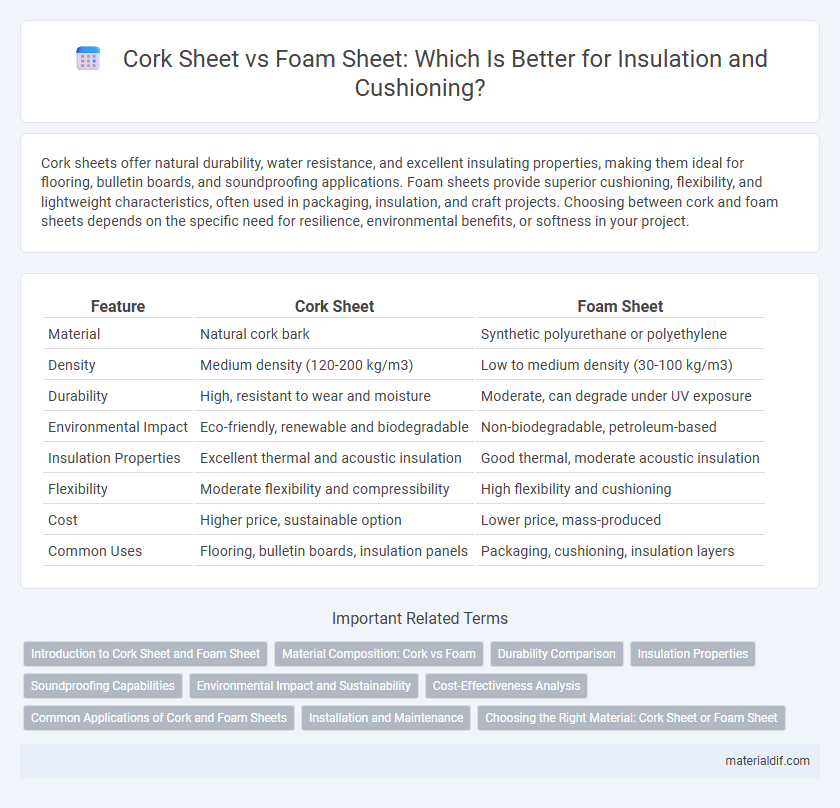

Table of Comparison

| Feature | Cork Sheet | Foam Sheet |

|---|---|---|

| Material | Natural cork bark | Synthetic polyurethane or polyethylene |

| Density | Medium density (120-200 kg/m3) | Low to medium density (30-100 kg/m3) |

| Durability | High, resistant to wear and moisture | Moderate, can degrade under UV exposure |

| Environmental Impact | Eco-friendly, renewable and biodegradable | Non-biodegradable, petroleum-based |

| Insulation Properties | Excellent thermal and acoustic insulation | Good thermal, moderate acoustic insulation |

| Flexibility | Moderate flexibility and compressibility | High flexibility and cushioning |

| Cost | Higher price, sustainable option | Lower price, mass-produced |

| Common Uses | Flooring, bulletin boards, insulation panels | Packaging, cushioning, insulation layers |

Introduction to Cork Sheet and Foam Sheet

Cork sheets, made from the bark of cork oak trees, provide a natural, renewable material prized for its lightweight, water-resistant, and insulating properties. Foam sheets, typically crafted from polyurethane, polyethylene, or EVA, offer versatile cushioning, thermal insulation, and shock absorption, widely used in packaging and construction. Both materials serve distinct purposes based on durability, flexibility, and environmental impact, influencing their application in various industries.

Material Composition: Cork vs Foam

Cork sheets are composed of natural bark harvested from cork oak trees, offering renewable and biodegradable properties with excellent moisture resistance and breathability. Foam sheets, typically made from synthetic materials such as polyurethane or polyethylene, provide lightweight cushioning and strong insulation but lack biodegradability and natural vapor permeability. The material composition of cork ensures eco-friendly durability, while foam's synthetic makeup prioritizes flexibility and impact absorption.

Durability Comparison

Cork sheets offer exceptional durability due to their natural resilience, resistance to moisture, and ability to maintain structural integrity over time, making them ideal for long-term applications. Foam sheets, while lightweight and flexible, tend to degrade faster under mechanical stress and exposure to environmental factors such as UV rays and humidity. The inherent toughness of cork ensures superior longevity compared to the relatively short lifespan of most foam sheet materials.

Insulation Properties

Cork sheets provide excellent thermal and acoustic insulation due to their natural cellular structure, which traps air and reduces heat transfer effectively. Foam sheets, such as polyurethane or polystyrene, offer high R-values per inch and are lightweight, making them suitable for insulation where space-saving and moisture resistance are crucial. Cork excels in sustainable insulation with breathability and natural fire resistance, while foam sheets deliver superior insulation performance and versatility in construction applications.

Soundproofing Capabilities

Cork sheets provide superior soundproofing due to their natural cellular structure that effectively absorbs and dampens sound vibrations, making them ideal for noise reduction in walls and floors. Foam sheets, often made from polyurethane or melamine, offer sound absorption but typically lack the density of cork, resulting in less effective soundproofing, especially against low-frequency noises. For optimal acoustic insulation, cork sheets outperform foam sheets by combining environmental friendliness with robust noise attenuation properties.

Environmental Impact and Sustainability

Cork sheets are highly sustainable due to their renewable harvesting from cork oak trees without tree felling, enabling continuous growth and carbon sequestration. Foam sheets, especially those made from petrochemicals, exhibit significant environmental drawbacks including non-biodegradability and high carbon footprints from production. Cork's biodegradability and recyclability make it an eco-friendlier choice over synthetic foam materials in sustainable design and insulation applications.

Cost-Effectiveness Analysis

Cork sheets typically offer greater cost-effectiveness than foam sheets due to their natural durability and insulation properties, reducing long-term replacement and energy costs. Foam sheets often have lower upfront prices but may degrade faster, leading to more frequent replacements and higher maintenance expenses. In projects prioritizing sustainability and lifespan, cork sheets provide better overall value despite a higher initial investment.

Common Applications of Cork and Foam Sheets

Cork sheets are commonly used in flooring, bulletin boards, insulation, and gaskets due to their natural resilience, water resistance, and thermal properties. Foam sheets find widespread application in packaging, cushioning, soundproofing, and crafting because of their lightweight, shock-absorbing, and flexible characteristics. Both materials serve versatile roles across construction, automotive, and creative industries, optimizing comfort, protection, and durability.

Installation and Maintenance

Cork sheets are easier to install due to their natural flexibility and self-adhesive backing options, making them ideal for DIY projects and uneven surfaces. Foam sheets require precise cutting and often need adhesives or mechanical fasteners, which can complicate installation on porous or irregular areas. Cork sheets demand minimal maintenance, primarily needing regular dusting and occasional sealing to protect against moisture, whereas foam sheets may degrade faster under UV exposure and typically require more frequent replacement or cleaning.

Choosing the Right Material: Cork Sheet or Foam Sheet

Cork sheets offer superior natural insulation, durability, and eco-friendliness, making them ideal for sustainable construction and soundproofing projects. Foam sheets provide excellent cushioning, flexibility, and moisture resistance, suited for packaging, crafts, and thermal insulation applications. Selecting the right material depends on specific needs such as environmental impact, insulation properties, and mechanical resilience.

Cork Sheet vs Foam Sheet Infographic

materialdif.com

materialdif.com