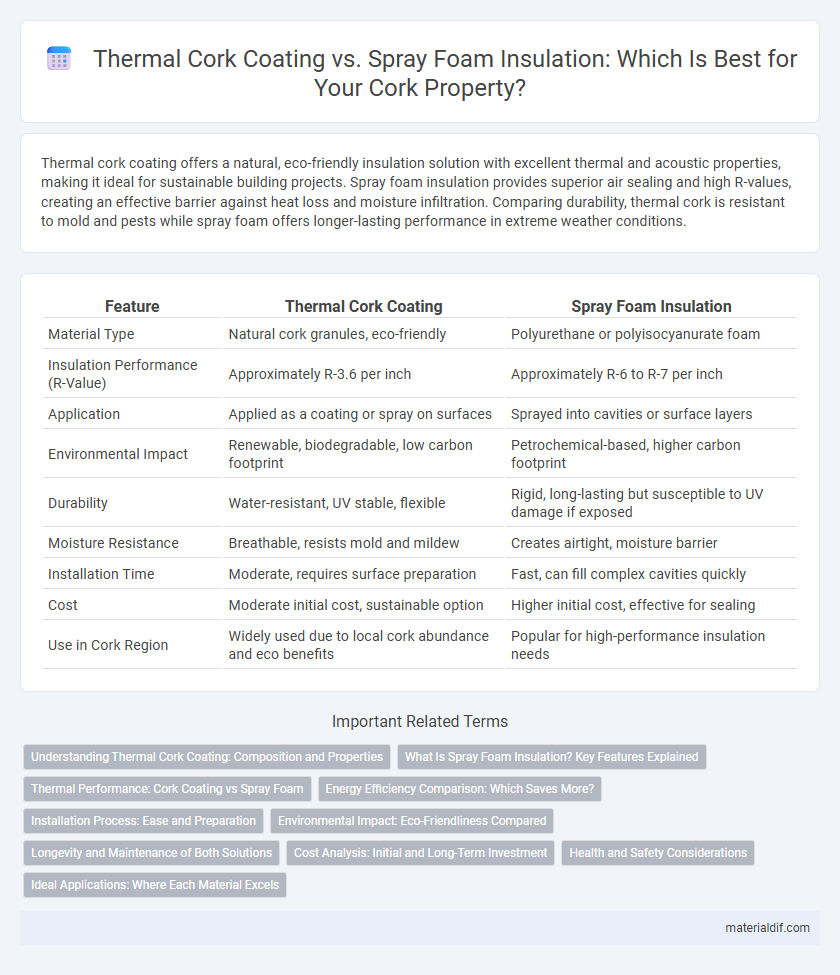

Thermal cork coating offers a natural, eco-friendly insulation solution with excellent thermal and acoustic properties, making it ideal for sustainable building projects. Spray foam insulation provides superior air sealing and high R-values, creating an effective barrier against heat loss and moisture infiltration. Comparing durability, thermal cork is resistant to mold and pests while spray foam offers longer-lasting performance in extreme weather conditions.

Table of Comparison

| Feature | Thermal Cork Coating | Spray Foam Insulation |

|---|---|---|

| Material Type | Natural cork granules, eco-friendly | Polyurethane or polyisocyanurate foam |

| Insulation Performance (R-Value) | Approximately R-3.6 per inch | Approximately R-6 to R-7 per inch |

| Application | Applied as a coating or spray on surfaces | Sprayed into cavities or surface layers |

| Environmental Impact | Renewable, biodegradable, low carbon footprint | Petrochemical-based, higher carbon footprint |

| Durability | Water-resistant, UV stable, flexible | Rigid, long-lasting but susceptible to UV damage if exposed |

| Moisture Resistance | Breathable, resists mold and mildew | Creates airtight, moisture barrier |

| Installation Time | Moderate, requires surface preparation | Fast, can fill complex cavities quickly |

| Cost | Moderate initial cost, sustainable option | Higher initial cost, effective for sealing |

| Use in Cork Region | Widely used due to local cork abundance and eco benefits | Popular for high-performance insulation needs |

Understanding Thermal Cork Coating: Composition and Properties

Thermal cork coating is made from natural cork granules bound with resins or adhesives, offering excellent thermal insulation and eco-friendly benefits. Its cellular structure provides high compressive strength, moisture resistance, and breathability, making it ideal for sustainable building applications. Unlike spray foam insulation, thermal cork coating maintains its insulating properties without off-gassing or chemical emissions, ensuring long-term durability and indoor air quality.

What Is Spray Foam Insulation? Key Features Explained

Spray foam insulation is a versatile material composed of polyurethane that expands upon application to fill gaps and create an airtight seal, enhancing energy efficiency in buildings. It offers superior thermal resistance with an R-value typically ranging from 6 to 7 per inch, significantly reducing heat transfer compared to traditional insulation methods like thermal cork coating. Spray foam also acts as a moisture barrier and sound insulator, providing long-term durability and preventing mold growth in varied climates such as those found in Cork.

Thermal Performance: Cork Coating vs Spray Foam

Thermal cork coating provides excellent insulation by creating a breathable barrier that regulates temperature and resists moisture, making it ideal for energy-efficient buildings. Spray foam insulation offers higher R-values per inch, sealing gaps and preventing air leaks effectively, which enhances overall thermal performance. While spray foam achieves superior thermal resistance, cork coating excels in sustainability and vapor permeability, contributing to long-term indoor comfort.

Energy Efficiency Comparison: Which Saves More?

Thermal cork coating offers excellent thermal insulation properties with an R-value typically around 3.6 per inch, enabling effective reduction of heat transfer and improved energy efficiency in buildings. Spray foam insulation, particularly closed-cell foam, boasts higher R-values of approximately 6 to 7 per inch, providing superior air sealing and moisture resistance that further enhances energy savings. While spray foam insulation generally delivers greater energy efficiency due to its higher R-value and airtightness, thermal cork coating remains a sustainable, eco-friendly option with natural breathability and resistance to mold and pests.

Installation Process: Ease and Preparation

Thermal cork coating requires minimal surface preparation and can be easily applied with rollers or sprayers, making it a user-friendly option for sealing walls and roofs. Spray foam insulation demands thorough surface cleaning and precise moisture control before application, involving specialized equipment and professional installation for effective air sealing. Cork's natural flexibility allows for quicker curing times compared to spray foam, which needs controlled conditions to expand and set properly.

Environmental Impact: Eco-Friendliness Compared

Thermal cork coating offers a sustainable insulation solution derived from renewable cork oak bark, which is biodegradable and recyclable, reducing landfill waste and lowering carbon footprint. Spray foam insulation, often petroleum-based and containing harmful blowing agents, can release volatile organic compounds (VOCs) and pose disposal challenges, impacting indoor air quality and the environment negatively. Cork's natural properties enhance thermal performance while maintaining eco-friendliness, positioning it as a greener choice compared to conventional spray foam materials.

Longevity and Maintenance of Both Solutions

Thermal cork coating offers exceptional longevity due to its natural resistance to moisture, UV rays, and microbial growth, requiring minimal maintenance over decades. Spray foam insulation, while effective for airtightness and thermal performance, tends to degrade faster under prolonged UV exposure and may necessitate periodic inspections and repairs. Cork's sustainable, durable properties make it a low-maintenance solution compared to the higher upkeep demands of spray foam insulation.

Cost Analysis: Initial and Long-Term Investment

Thermal cork coating offers a lower initial investment compared to spray foam insulation, with material and application costs that are typically 30-50% less expensive. Over the long term, cork's natural durability and resistance to moisture reduce maintenance expenses, potentially saving up to 20% in repair and replacement costs over 10 years. Spray foam insulation, while more expensive upfront, provides superior air sealing and energy efficiency, which can result in greater utility bill savings that may offset the higher initial cost within 5 to 8 years.

Health and Safety Considerations

Thermal cork coating offers a non-toxic, mold-resistant insulation option with natural antifungal properties, making it safer for indoor air quality compared to spray foam insulation, which can release volatile organic compounds (VOCs) during application and curing. Cork's natural breathability reduces the risk of moisture buildup and related health issues, whereas spray foam may trap moisture, promoting mold growth if not properly installed. Choosing thermal cork coating minimizes exposure to harmful chemicals and enhances long-term occupant health and safety.

Ideal Applications: Where Each Material Excels

Thermal cork coating excels in sustainable building projects, offering superior breathability and moisture resistance ideal for roofing and exterior walls. Spray foam insulation is best suited for airtight sealing in residential and commercial buildings, particularly in areas requiring high R-values and fast application. Cork's natural thermal properties perform well in eco-conscious renovations, while spray foam delivers unmatched insulation in tight spaces and irregular cavities.

Thermal Cork Coating vs Spray Foam Insulation Infographic

materialdif.com

materialdif.com