Agglomerated cork is made from small cork granules bonded together, offering greater durability and cost-effectiveness compared to solid cork, which is harvested as a single piece from the cork oak bark. Solid cork provides superior natural insulation and elasticity, making it ideal for premium applications, whereas agglomerated cork is favored for its uniformity and versatility in flooring and wall coverings. Choosing between agglomerated and solid cork depends on the balance of budget, performance, and aesthetic preferences.

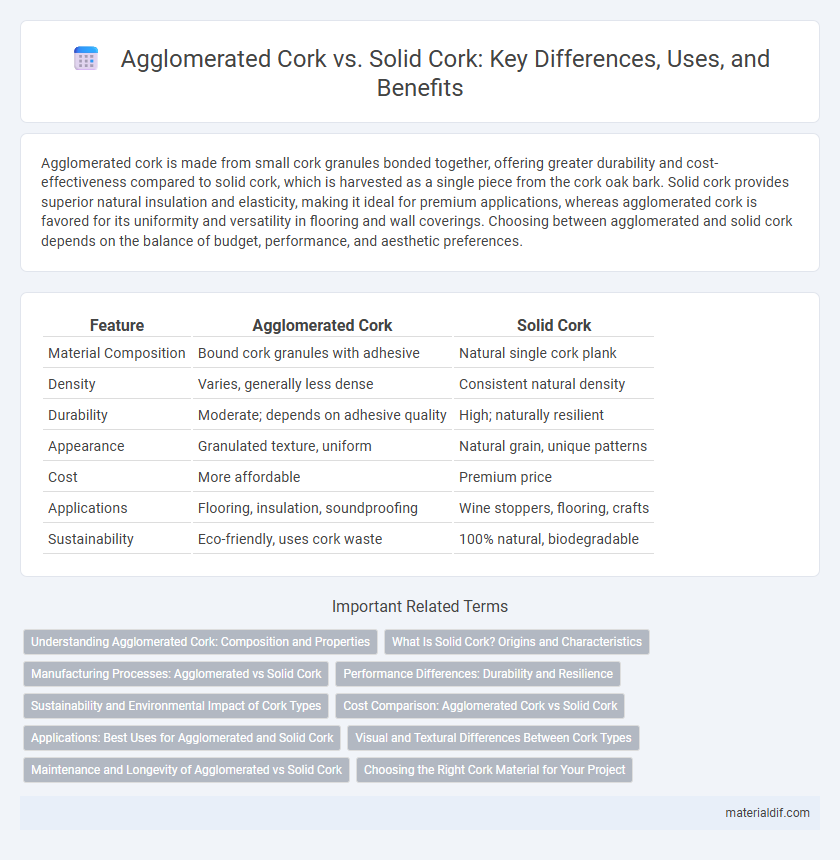

Table of Comparison

| Feature | Agglomerated Cork | Solid Cork |

|---|---|---|

| Material Composition | Bound cork granules with adhesive | Natural single cork plank |

| Density | Varies, generally less dense | Consistent natural density |

| Durability | Moderate; depends on adhesive quality | High; naturally resilient |

| Appearance | Granulated texture, uniform | Natural grain, unique patterns |

| Cost | More affordable | Premium price |

| Applications | Flooring, insulation, soundproofing | Wine stoppers, flooring, crafts |

| Sustainability | Eco-friendly, uses cork waste | 100% natural, biodegradable |

Understanding Agglomerated Cork: Composition and Properties

Agglomerated cork consists of cork granules bonded together with resin or adhesives, creating a dense and uniform material ideal for insulation and flooring applications. Its composition offers enhanced durability and dimensional stability compared to solid cork, which is harvested in large, natural sheets from cork oak bark. The properties of agglomerated cork, including improved resistance to moisture and wear, make it a versatile alternative for sustainable building materials and acoustic solutions.

What Is Solid Cork? Origins and Characteristics

Solid cork is harvested directly from the bark of Quercus suber, the cork oak tree native to the Mediterranean region, particularly abundant in Portugal and Spain. This natural material is valued for its elasticity, impermeability, and lightweight properties, making it ideal for wine stoppers, flooring, and insulation. Unlike agglomerated cork, which is made by binding cork granules with adhesives, solid cork retains its continuous cellular structure, providing superior durability and moisture resistance.

Manufacturing Processes: Agglomerated vs Solid Cork

Agglomerated cork is produced by binding small cork granules with resin or natural adhesives, resulting in a versatile, cost-effective material suitable for various industrial uses. Solid cork, on the other hand, is harvested directly from the bark of the cork oak tree and processed into large, uniform sheets or blocks through a natural curing and drying method that preserves its cellular structure and elasticity. Manufacturing solid cork requires more time and precision to maintain quality and natural properties, while agglomerated cork allows for greater customization and efficient utilization of cork by-products.

Performance Differences: Durability and Resilience

Agglomerated cork consists of cork granules bonded with adhesive, offering consistent density but slightly reduced durability compared to solid cork, which is harvested in whole pieces and retains natural cellular structure. Solid cork demonstrates superior resilience and longevity due to its intact cellular makeup, providing enhanced resistance to wear, compression, and moisture. While agglomerated cork is cost-effective and versatile, solid cork outperforms in applications demanding maximum durability and long-term performance.

Sustainability and Environmental Impact of Cork Types

Agglomerated cork, made from recycled cork granules, offers a sustainable alternative by utilizing cork waste and reducing environmental impact compared to solid cork. Solid cork, harvested directly from cork oak trees without killing them, supports biodiversity and carbon sequestration, but its production can be limited by slower regeneration rates. Both types promote eco-friendly practices, yet agglomerated cork further enhances sustainability through efficient resource use and lower carbon footprint in manufacturing.

Cost Comparison: Agglomerated Cork vs Solid Cork

Agglomerated cork is generally more cost-effective than solid cork due to its manufacturing process that utilizes cork granules bonded with adhesive, reducing material waste and production expenses. Solid cork, made from a single piece of natural cork, commands a higher price because of its durability, aesthetic appeal, and limited availability. For flooring or insulation projects, agglomerated cork provides an economical alternative while solid cork delivers premium quality and longer lifespan, influencing budget decisions based on performance requirements.

Applications: Best Uses for Agglomerated and Solid Cork

Agglomerated cork, made from granulated cork bonded together, excels in flooring, underlayment, and insulation due to its cost-effectiveness and consistent density, making it ideal for large surface applications requiring durability and soundproofing. Solid cork, harvested from the bark of cork oak trees without granulation, is preferred for premium products like wine stoppers, bulletin boards, and high-end flooring because of its natural elasticity, moisture resistance, and aesthetic appeal. Both types serve complementary roles in construction and design, with agglomerated cork optimized for performance-focused uses and solid cork chosen for applications demanding superior texture and resilience.

Visual and Textural Differences Between Cork Types

Agglomerated cork features a visibly speckled pattern due to its composite of ground cork pieces bonded with adhesive, offering a uniform texture that is slightly rougher and denser. Solid cork, made from a single cork bark layer, displays a natural, continuous grain with smoother, softer texture and more pronounced elasticity. Visual distinction is clear as solid cork preserves organic patterns and natural color variations, whereas agglomerated cork presents a more homogenized and engineered appearance.

Maintenance and Longevity of Agglomerated vs Solid Cork

Agglomerated cork requires more frequent sealing and cleaning to maintain its durability, as the granulated structure is more susceptible to moisture penetration and wear compared to solid cork. Solid cork, being a natural, continuous piece, offers superior longevity and resists damage better with minimal maintenance due to its inherent density and natural elasticity. Proper care of agglomerated cork involves regular application of protective finishes, while solid cork typically endures longer with simple, routine upkeep.

Choosing the Right Cork Material for Your Project

Agglomerated cork consists of granulated cork particles bonded with resin, making it more affordable and versatile for insulation, flooring, and craft projects, while solid cork offers superior durability, elasticity, and natural water resistance ideal for premium applications like wine stoppers and high-end flooring. Selecting the right material depends on the project's demands for strength, sustainability, and appearance; agglomerated cork suits budget-conscious, large-scale use, whereas solid cork provides enhanced performance and aesthetics. Consider factors such as density, compressibility, and intended lifespan to optimize the functionality and cost-efficiency of your cork-based project.

Agglomerated Cork vs Solid Cork Infographic

materialdif.com

materialdif.com