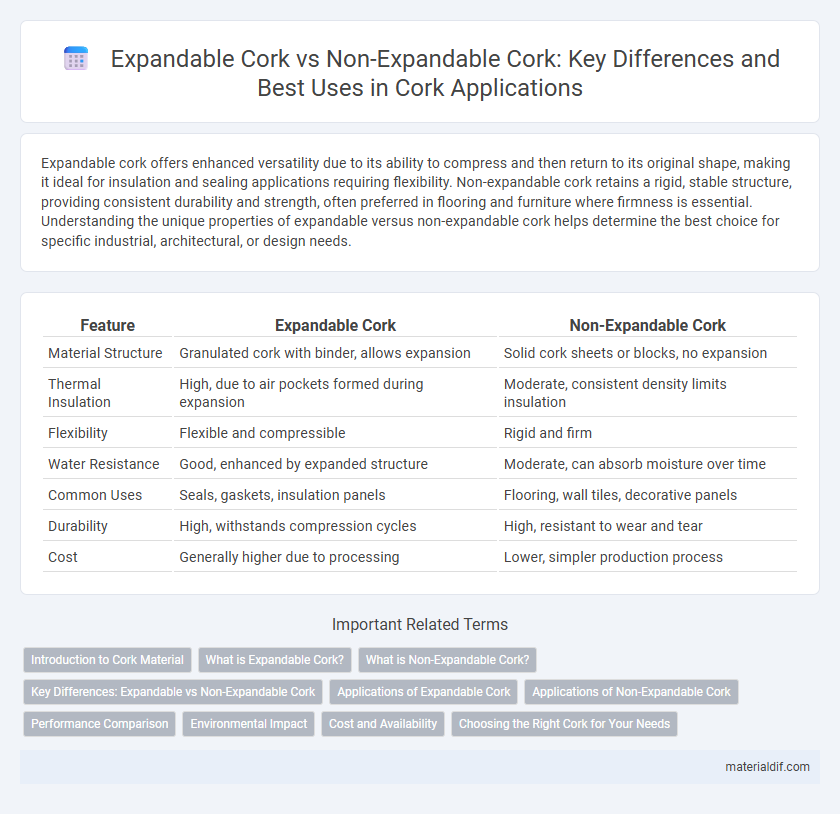

Expandable cork offers enhanced versatility due to its ability to compress and then return to its original shape, making it ideal for insulation and sealing applications requiring flexibility. Non-expandable cork retains a rigid, stable structure, providing consistent durability and strength, often preferred in flooring and furniture where firmness is essential. Understanding the unique properties of expandable versus non-expandable cork helps determine the best choice for specific industrial, architectural, or design needs.

Table of Comparison

| Feature | Expandable Cork | Non-Expandable Cork |

|---|---|---|

| Material Structure | Granulated cork with binder, allows expansion | Solid cork sheets or blocks, no expansion |

| Thermal Insulation | High, due to air pockets formed during expansion | Moderate, consistent density limits insulation |

| Flexibility | Flexible and compressible | Rigid and firm |

| Water Resistance | Good, enhanced by expanded structure | Moderate, can absorb moisture over time |

| Common Uses | Seals, gaskets, insulation panels | Flooring, wall tiles, decorative panels |

| Durability | High, withstands compression cycles | High, resistant to wear and tear |

| Cost | Generally higher due to processing | Lower, simpler production process |

Introduction to Cork Material

Cork material is derived from the bark of the Cork oak tree, primarily found in the Mediterranean region, with Portugal leading global production. Expandable cork undergoes a heating process to become flexible, allowing it to expand and form various shapes, making it ideal for insulation and sealing applications. Non-expandable cork retains its natural rigid structure, commonly used in flooring, bulletin boards, and decorative items due to its durability and natural texture.

What is Expandable Cork?

Expandable cork, also known as agglomerated cork, is produced by heating granulated cork, causing it to expand and bind naturally without synthetic adhesives, resulting in a lightweight and flexible material. Its cellular structure enhances thermal insulation, soundproofing, and elasticity, making it ideal for applications such as flooring, insulation, and sealing. Unlike non-expandable cork, which is harvested directly in solid sheets, expandable cork can be molded into various shapes and densities for versatile industrial and architectural uses.

What is Non-Expandable Cork?

Non-expandable cork, also known as raw cork, is harvested directly from the bark without undergoing any processing to increase its volume or flexibility. It retains its natural density and rigidity, making it ideal for applications requiring firm, durable material such as flooring and insulation. Compared to expandable cork, non-expandable cork offers less elasticity but provides superior strength and resistance to wear.

Key Differences: Expandable vs Non-Expandable Cork

Expandable cork features a cellular structure that allows it to expand multiple times its original size when heated, making it ideal for sealing bottles and insulation. Non-expandable cork, derived from the outer bark of cork oak trees, retains its natural shape and density, providing consistent durability and moisture resistance without expansion. The key differences lie in their applications and physical properties: expandable cork is preferred for caps and plugs due to its compressibility, while non-expandable cork is well-suited for flooring, wall coverings, and craft materials requiring stability.

Applications of Expandable Cork

Expandable cork's unique ability to be molded under heat and pressure makes it ideal for insulation in construction, automotive components, and soundproofing solutions. Its renewable, lightweight, and fire-resistant properties enhance energy efficiency in buildings and provide durable cushioning in sports equipment and footwear. Non-expandable cork, lacking these expandable properties, is primarily used in flooring, wine stoppers, and decorative items.

Applications of Non-Expandable Cork

Non-expandable cork is widely used in applications requiring stability and precise dimensions, such as flooring, insulation panels, and bulletin boards. Its natural cellular structure provides excellent thermal and acoustic insulation, making it ideal for construction and interior design. Unlike expandable cork, it resists deformation and maintains consistent density, ensuring durability in industrial and household products.

Performance Comparison

Expandable cork exhibits superior insulation and sound absorption due to its cellular structure that expands during processing, resulting in a denser and more resilient material. Non-expandable cork, while still durable and water-resistant, lacks the enhanced elasticity and thermal regulation properties found in expandable cork. Performance tests highlight that expandable cork outperforms non-expandable types in energy efficiency and longevity, making it ideal for eco-friendly construction and design applications.

Environmental Impact

Expandable cork, harvested from the bark of Quercus suber trees without cutting them down, supports sustainable forestry and reduces carbon emissions by promoting forest regeneration. Non-expandable cork, obtained through more invasive extraction methods, can lead to habitat disruption and slower ecological recovery, increasing the environmental footprint. Using expandable cork in products enhances biodiversity conservation and decreases waste, reinforcing its eco-friendly advantage over non-expandable alternatives.

Cost and Availability

Expandable cork, derived from heating natural cork granules, typically incurs higher production costs, translating to a more expensive price point compared to non-expandable cork. Non-expandable cork, often sourced directly from traditional cork oak harvesting, tends to be more readily available and cost-effective due to simpler processing methods. Market availability of expandable cork remains limited, while non-expandable cork enjoys broader distribution in construction and insulation applications.

Choosing the Right Cork for Your Needs

Expandable cork offers superior insulation and flexibility, making it ideal for thermal and acoustic applications, while non-expandable cork provides consistent density and durability suitable for flooring and decorative uses. Selecting the right cork depends on your project's specific requirements for compression, expansion, and environmental resistance. Understanding these material properties ensures optimal performance and longevity in your cork-based solutions in Cork and beyond.

Expandable Cork vs Non-Expandable Cork Infographic

materialdif.com

materialdif.com