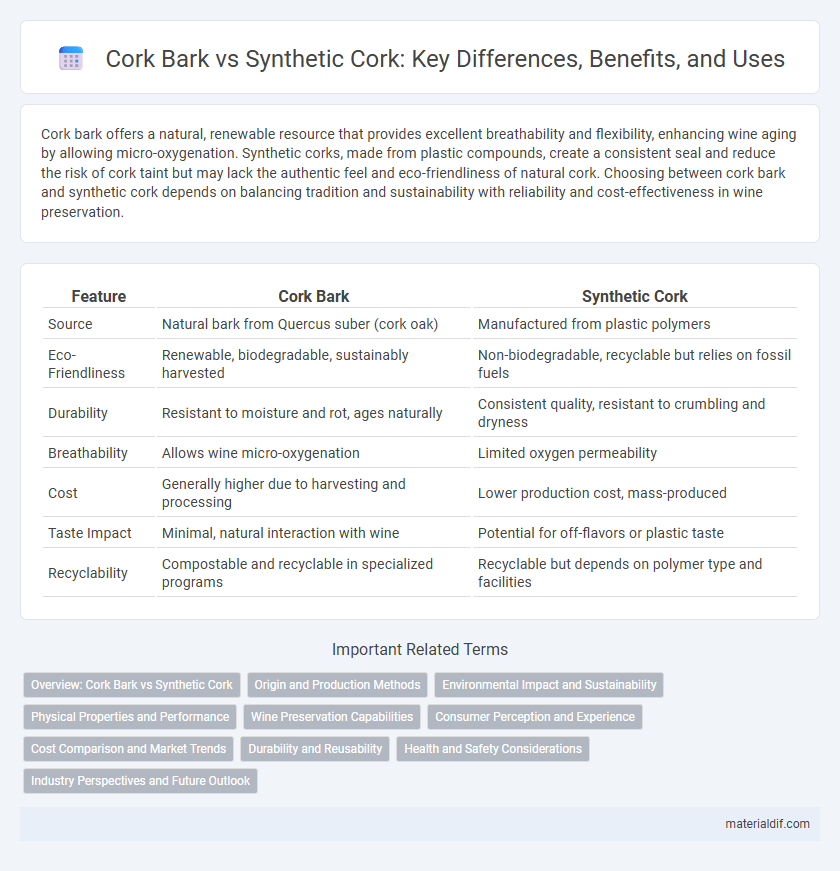

Cork bark offers a natural, renewable resource that provides excellent breathability and flexibility, enhancing wine aging by allowing micro-oxygenation. Synthetic corks, made from plastic compounds, create a consistent seal and reduce the risk of cork taint but may lack the authentic feel and eco-friendliness of natural cork. Choosing between cork bark and synthetic cork depends on balancing tradition and sustainability with reliability and cost-effectiveness in wine preservation.

Table of Comparison

| Feature | Cork Bark | Synthetic Cork |

|---|---|---|

| Source | Natural bark from Quercus suber (cork oak) | Manufactured from plastic polymers |

| Eco-Friendliness | Renewable, biodegradable, sustainably harvested | Non-biodegradable, recyclable but relies on fossil fuels |

| Durability | Resistant to moisture and rot, ages naturally | Consistent quality, resistant to crumbling and dryness |

| Breathability | Allows wine micro-oxygenation | Limited oxygen permeability |

| Cost | Generally higher due to harvesting and processing | Lower production cost, mass-produced |

| Taste Impact | Minimal, natural interaction with wine | Potential for off-flavors or plastic taste |

| Recyclability | Compostable and recyclable in specialized programs | Recyclable but depends on polymer type and facilities |

Overview: Cork Bark vs Synthetic Cork

Cork bark, harvested from the Quercus suber tree, provides a natural, renewable material renowned for its elasticity, breathability, and biodegradability, making it a preferred choice for wine stoppers and insulation. Synthetic cork, made from plastic compounds such as polyethylene or elastomers, offers consistent quality, resistance to cork taint, and cost-effectiveness, but lacks the ecological benefits and aging properties of natural cork. In Cork, Ireland, the debate between cork bark and synthetic cork centers on balancing environmental sustainability, product performance, and economic factors within the wine industry.

Origin and Production Methods

Cork bark, harvested from the Quercus suber tree primarily found in the Mediterranean region, is sustainably stripped by hand every 9 to 12 years without harming the tree, ensuring natural regeneration. Synthetic cork is produced using plastic compounds or foam materials through molding or injection processes, relying on petrochemical resources rather than natural growth. The traditional harvesting of cork bark emphasizes environmental sustainability, while synthetic cork production focuses on industrial manufacturing efficiency.

Environmental Impact and Sustainability

Cork bark, harvested from cork oak trees primarily in Portugal and Spain, offers a renewable and biodegradable alternative to synthetic corks, which are typically made from petroleum-based plastics. The harvesting process of cork bark promotes forest conservation and supports biodiversity, as it does not harm the trees and allows them to continue absorbing CO2. In contrast, synthetic corks contribute to plastic pollution and have a higher carbon footprint, making cork bark a more environmentally sustainable choice for wine stoppers.

Physical Properties and Performance

Natural cork from Cork trees exhibits excellent elasticity, compressibility, and resilience, making it ideal for bottle stoppers due to its ability to expand and create a tight seal. Synthetic corks, crafted from plastic resins, offer more uniform density and resistance to moisture but lack the natural cell structure that provides the breathability and flexibility of genuine cork bark. The physical properties of natural cork, including its lightweight and thermal insulation, outperform synthetic alternatives in preserving wine quality and preventing oxidation during storage.

Wine Preservation Capabilities

Natural cork from Cork oak trees offers superior oxygen permeability control, creating an ideal micro-oxygenation that preserves wine's complexity and longevity. Synthetic corks, typically made from plastic polymers, lack this nuanced breathability, often resulting in faster oxidation and flavor degradation. Studies show wines sealed with natural cork maintain fresher aroma profiles and develop more balanced aging characteristics compared to those sealed with synthetic alternatives.

Consumer Perception and Experience

Consumers often perceive natural cork as more authentic and environmentally friendly compared to synthetic cork, associating it with tradition and premium quality in wine preservation. Sensory experiences also lean towards natural cork, as it allows gradual oxygen exchange that enhances wine aging, whereas synthetic corks may alter taste due to different sealing properties. Despite synthetic cork's durability and consistency, many wine enthusiasts favor natural cork for its role in maintaining wine integrity and its biodegradable nature.

Cost Comparison and Market Trends

Natural cork, harvested from the bark of cork oak trees primarily in Portugal and Spain, typically commands a higher price point due to its sustainable harvesting process and superior aging properties. Synthetic corks, made from plastic polymers, offer a cost-effective alternative favored by wine producers aiming to reduce expenses and prevent cork taint, impacting approximately 5% of natural cork production. Market trends indicate a steady demand for natural cork driven by eco-conscious consumers, while synthetic corks gain traction in lower-priced wines and sparkling beverages, reflecting a dynamic balance between quality perception and cost efficiency.

Durability and Reusability

Cork bark offers superior durability due to its natural elasticity and resistance to degradation, making it highly reusable in wine stoppers and craft products. Synthetic corks, while consistent in shape and less prone to contamination, often lack the long-term resilience and eco-friendly qualities of genuine cork bark. Cork bark's renewable nature and ability to maintain performance through multiple uses position it as a sustainable choice compared to synthetic alternatives.

Health and Safety Considerations

Natural cork bark offers superior breathability and is free from harmful chemicals, reducing risks of allergic reactions and ensuring safer contact with food and beverages. Synthetic corks, often made from plastics, may release microplastics or contain substances that pose potential health concerns over prolonged exposure. Proper selection between cork bark and synthetic cork is essential to minimize health risks and maintain safety standards in packaging.

Industry Perspectives and Future Outlook

The Cork industry emphasizes the natural bark's sustainability, biodegradability, and superior oxygen permeability essential for premium wine quality, maintaining its market dominance despite rising synthetic alternatives. Synthetic corks are valued for consistency, cost efficiency, and resistance to cork taint but face challenges in consumer perception and environmental impact. Industry trends show innovation in cork harvesting technology and hybrid closures, suggesting a future where natural cork remains relevant through enhanced sustainability and performance.

Cork bark vs Synthetic cork Infographic

materialdif.com

materialdif.com