Cork tape offers natural durability and excellent moisture resistance, making it ideal for sealing and insulation in various applications, while foam tape provides superior cushioning and flexibility, perfect for impact absorption and sound dampening. Cork tape is typically heat-resistant and environmentally friendly, whereas foam tape excels in adhesive strength and conforms well to irregular surfaces. Choosing between cork tape and foam tape depends on the specific needs for durability, insulation, or cushioning in your project.

Table of Comparison

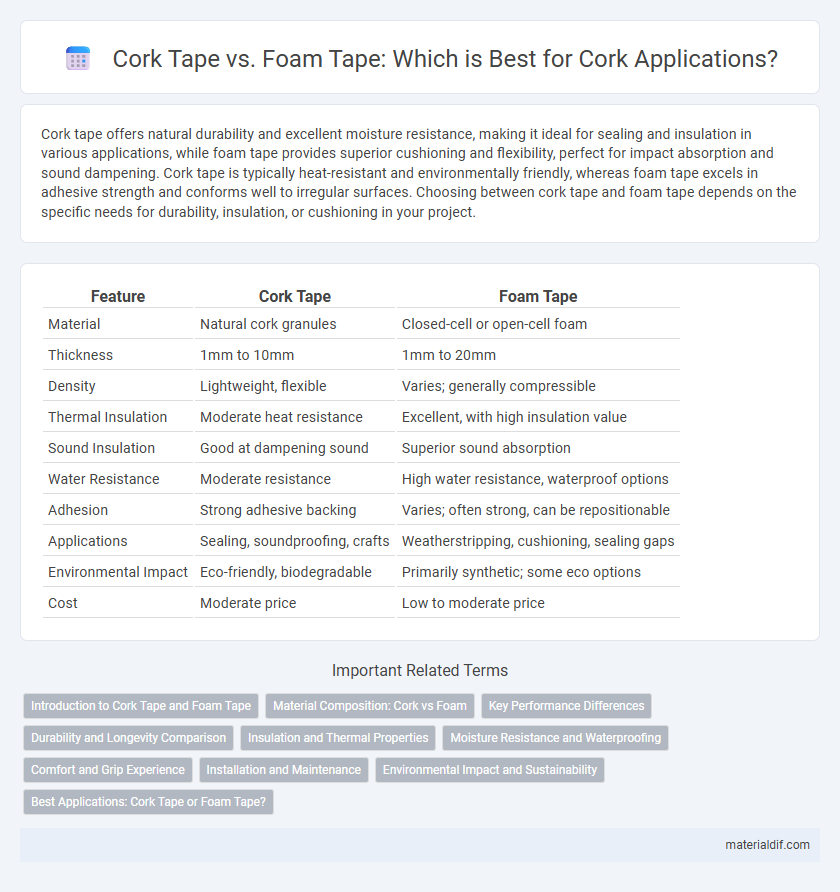

| Feature | Cork Tape | Foam Tape |

|---|---|---|

| Material | Natural cork granules | Closed-cell or open-cell foam |

| Thickness | 1mm to 10mm | 1mm to 20mm |

| Density | Lightweight, flexible | Varies; generally compressible |

| Thermal Insulation | Moderate heat resistance | Excellent, with high insulation value |

| Sound Insulation | Good at dampening sound | Superior sound absorption |

| Water Resistance | Moderate resistance | High water resistance, waterproof options |

| Adhesion | Strong adhesive backing | Varies; often strong, can be repositionable |

| Applications | Sealing, soundproofing, crafts | Weatherstripping, cushioning, sealing gaps |

| Environmental Impact | Eco-friendly, biodegradable | Primarily synthetic; some eco options |

| Cost | Moderate price | Low to moderate price |

Introduction to Cork Tape and Foam Tape

Cork tape is a natural, eco-friendly material known for its excellent thermal insulation, soundproofing, and cushioning properties, making it ideal for sealing gaps and protecting surfaces in construction and crafts. Foam tape, typically made from polyethylene or polyurethane, offers superior flexibility, moisture resistance, and adhesive performance, commonly used for weather stripping, mounting, and sealing applications. Choosing between cork tape and foam tape depends on the specific application needs regarding durability, environmental impact, and sealing efficiency.

Material Composition: Cork vs Foam

Cork tape is made from natural cork granules bound with adhesive resins, offering excellent durability, flexibility, and natural resistance to moisture and heat. Foam tape, typically composed of polyethylene, polyurethane, or PVC foam, provides superior cushioning, sealing, and insulation properties due to its lightweight and compressible structure. The choice between cork and foam tape depends on specific application needs, balancing cork's natural resilience with foam's enhanced thermal and acoustic insulation capabilities.

Key Performance Differences

Cork tape offers superior compressibility and excellent moisture resistance, making it ideal for sealing and cushioning applications where flexibility and water sealing are crucial. Foam tape provides higher thermal insulation and enhanced noise reduction due to its cellular structure, which traps air effectively for improved energy efficiency. Choosing between cork and foam tape depends on the priority of durability against environmental factors versus insulation properties in various industrial and construction uses.

Durability and Longevity Comparison

Cork tape offers exceptional durability with natural resistance to wear, moisture, and temperature fluctuations, making it ideal for long-term sealing applications in Cork's humid climate. Foam tape, while providing superior flexibility and cushioning, tends to degrade faster under UV exposure and heavy compression, reducing its lifespan compared to cork tape. In environments like Cork where durability and longevity are critical, cork tape outperforms foam tape by maintaining integrity and adhesion over extended periods.

Insulation and Thermal Properties

Cork tape offers superior natural insulation with high thermal resistance, making it ideal for reducing heat loss and preventing condensation in construction applications. Foam tape provides effective thermal insulation through its closed-cell structure, which traps air and minimizes heat transfer, but may degrade faster under UV exposure. Choosing between cork tape and foam tape depends on specific insulation needs, environmental durability, and thermal performance requirements.

Moisture Resistance and Waterproofing

Cork tape offers moderate moisture resistance due to its natural cellular structure, making it suitable for applications requiring breathability but limited waterproofing. Foam tape, particularly closed-cell variants, provides superior waterproofing and moisture barrier properties, ideal for sealing and insulation in damp or wet environments. Choosing between cork tape and foam tape depends on the level of moisture exposure and the need for water impermeability in Cork-specific construction or repair projects.

Comfort and Grip Experience

Cork tape offers a natural cushioning effect that enhances comfort by adapting to hand contours and reducing vibration, ideal for prolonged use in sports like cycling. Foam tape provides superior grip through its dense, spongy texture, which absorbs sweat and maintains tackiness even in humid conditions. Choosing between cork and foam tape depends on prioritizing cushioning comfort versus a consistently secure grip during intense activities.

Installation and Maintenance

Cork tape offers straightforward installation with its flexible material that easily conforms to uneven surfaces, requiring minimal adhesive for strong bonding. Foam tape, while also easy to install, demands careful surface preparation to ensure proper adhesion and prevent peeling over time. Maintenance for cork tape is low due to its natural resistance to moisture and mold, whereas foam tape may need periodic inspection for compression or deterioration in high-traffic or humid areas.

Environmental Impact and Sustainability

Cork tape, made from natural cork bark, offers a biodegradable and renewable alternative to foam tape, which typically consists of petroleum-based synthetic materials with limited recyclability. The production of cork tape involves minimal chemical processing, resulting in lower carbon emissions and a smaller ecological footprint compared to foam tape manufacturing. Cork tape's ability to decompose naturally without releasing harmful microplastics makes it a more environmentally sustainable choice for insulation and sealing applications.

Best Applications: Cork Tape or Foam Tape?

Cork tape excels in applications requiring natural cushioning and moisture resistance, making it ideal for sealing, insulation, and vibration damping in automotive and HVAC systems. Foam tape offers superior flexibility and strong adhesive properties, perfect for weatherstripping, mounting, and cushioning in electronics and construction. Choosing between cork tape and foam tape depends on factors like environmental exposure, required compression, and surface compatibility.

Cork Tape vs Foam Tape Infographic

materialdif.com

materialdif.com