Lightweight cork offers superior flexibility and comfort, making it ideal for pet products that require cushioning and breathability, such as collars and bedding. Heavyweight cork provides enhanced durability and resistance to wear, perfect for pet accessories exposed to rough use or outdoor conditions. Choosing between lightweight and heavyweight cork depends on balancing comfort with longevity in your pet's everyday items.

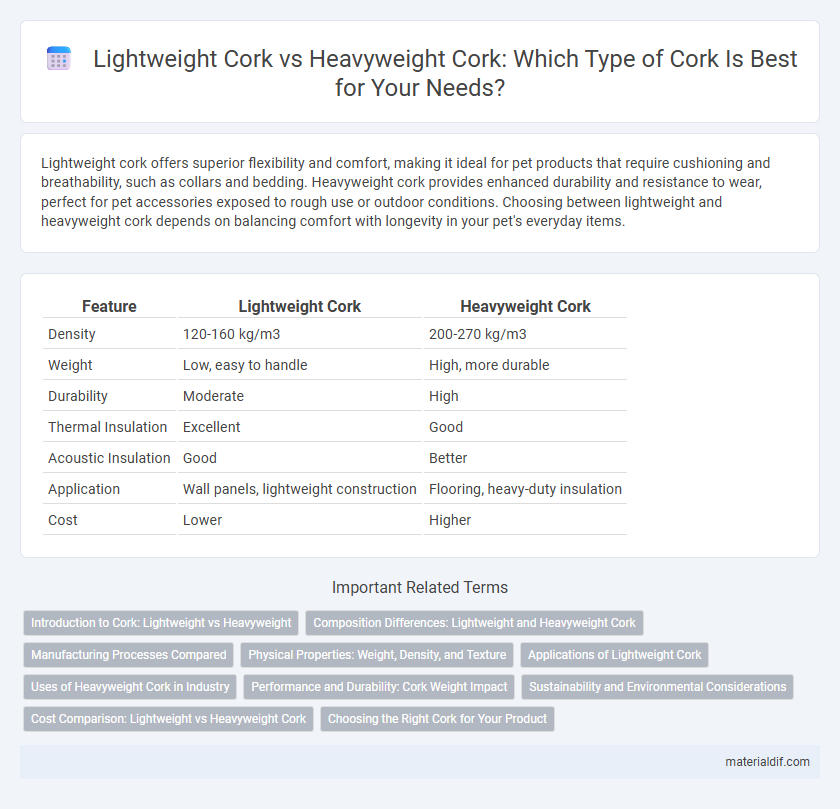

Table of Comparison

| Feature | Lightweight Cork | Heavyweight Cork |

|---|---|---|

| Density | 120-160 kg/m3 | 200-270 kg/m3 |

| Weight | Low, easy to handle | High, more durable |

| Durability | Moderate | High |

| Thermal Insulation | Excellent | Good |

| Acoustic Insulation | Good | Better |

| Application | Wall panels, lightweight construction | Flooring, heavy-duty insulation |

| Cost | Lower | Higher |

Introduction to Cork: Lightweight vs Heavyweight

Lightweight cork, characterized by its lower density and softer texture, is ideal for applications requiring flexibility and cushioning, such as footwear insoles and insulation panels. Heavyweight cork, with a higher density and greater durability, is preferred for structural purposes like flooring and wall coverings where impact resistance and longevity are essential. Both types of cork come from the cork oak tree (Quercus suber) native to the Mediterranean region, harvested sustainably every 9 to 12 years to preserve tree health.

Composition Differences: Lightweight and Heavyweight Cork

Lightweight cork typically contains a higher concentration of suberin and air-filled cells, giving it greater buoyancy and flexibility, while heavyweight cork has denser cellular structures with increased lignin content, enhancing its durability and compressive strength. The compositional variations influence their applications, where lightweight cork is favored for insulation and cushioning, and heavyweight cork excels in flooring and structural uses. These differences in cellulose, hemicellulose, and extractives contribute to their distinct physical properties and performance characteristics.

Manufacturing Processes Compared

Lightweight cork is produced by harvesting bark from younger cork oak trees, followed by a specific boiling process that softens the material, making it more flexible and easier to compress. Heavyweight cork, in contrast, is derived from older, denser bark and undergoes minimal boiling, preserving its natural firmness and durability. The distinct manufacturing processes impact the final product's density, resilience, and suitability for various applications like flooring or wine stoppers.

Physical Properties: Weight, Density, and Texture

Lightweight cork features a lower density, typically around 120-160 kg/m3, making it easier to handle and ideal for applications requiring flexibility and insulation. Heavyweight cork, with a density nearing 200-250 kg/m3, offers greater durability and mechanical strength, suitable for flooring and heavy-duty industrial uses. Texture in lightweight cork tends to be softer and more porous, while heavyweight cork exhibits a tighter, denser grain structure enhancing its resistance to compression and wear.

Applications of Lightweight Cork

Lightweight cork, known for its low density typically ranging between 100 to 200 kg/m3, is widely applied in thermal and acoustic insulation due to its superior compressibility and resilience. Its use extends to footwear, such as insoles and mid-soles, where lightweight comfort and shock absorption are essential. Compared to heavyweight cork, lightweight variants are favored in packaging and sports equipment for impact protection and cushioning without adding significant weight.

Uses of Heavyweight Cork in Industry

Heavyweight cork, characterized by its dense cellular structure that typically weighs over 240 kg/m3, is widely used in industrial applications requiring durability and exceptional insulation properties. Industries utilize heavyweight cork for vibration damping in machinery, thermal insulation in refrigeration units, and as gaskets or seals due to its compressibility and resistance to moisture. Its robust nature makes it ideal for heavy-duty flooring and impact protection in manufacturing plants, offering energy efficiency and operational safety.

Performance and Durability: Cork Weight Impact

Lightweight cork offers enhanced flexibility and cushioning, making it ideal for applications requiring shock absorption and comfort, such as footwear insoles or sports equipment. Heavyweight cork provides superior durability and structural support, benefiting uses in flooring and insulation where long-term resilience is crucial. The cork weight directly impacts performance by balancing resilience and flexibility, with heavier cork delivering greater strength and lightweight variants prioritizing comfort and adaptability.

Sustainability and Environmental Considerations

Lightweight cork production uses less raw material, reducing environmental impact and promoting resource efficiency compared to heavyweight cork, which requires thicker bark harvested less frequently. Both types are renewable and biodegradable, but lightweight cork supports sustainability by minimizing waste and energy consumption during processing. Choosing lightweight cork aligns with eco-friendly practices and reduces carbon footprint in various applications.

Cost Comparison: Lightweight vs Heavyweight Cork

Lightweight cork generally costs less due to lower material density and easier processing, making it a budget-friendly option for insulation and crafting. Heavyweight cork, though more expensive, offers superior durability, noise reduction, and thermal insulation, justifying its higher price in commercial and industrial applications. Comparing costs involves balancing initial investment with long-term performance benefits of each cork type.

Choosing the Right Cork for Your Product

Lightweight cork offers superior flexibility and cushioning, making it ideal for products requiring shock absorption and insulation, such as footwear and packaging materials. Heavyweight cork provides greater density and durability, suitable for flooring, wall coverings, and high-wear applications where strength and resilience are critical. Selecting the right cork depends on balancing factors like product function, desired durability, and cost efficiency to optimize performance and longevity.

Lightweight Cork vs Heavyweight Cork Infographic

materialdif.com

materialdif.com