Cork veneer offers a natural, thin layer of genuine cork that highlights its unique texture and eco-friendly benefits, making it ideal for decorative surfaces and furniture. Cork laminate combines a cork layer with a durable backing to enhance strength and wear resistance, suitable for flooring and high-traffic areas. Choosing between cork veneer and cork laminate depends on the desired balance between natural appearance and durability requirements.

Table of Comparison

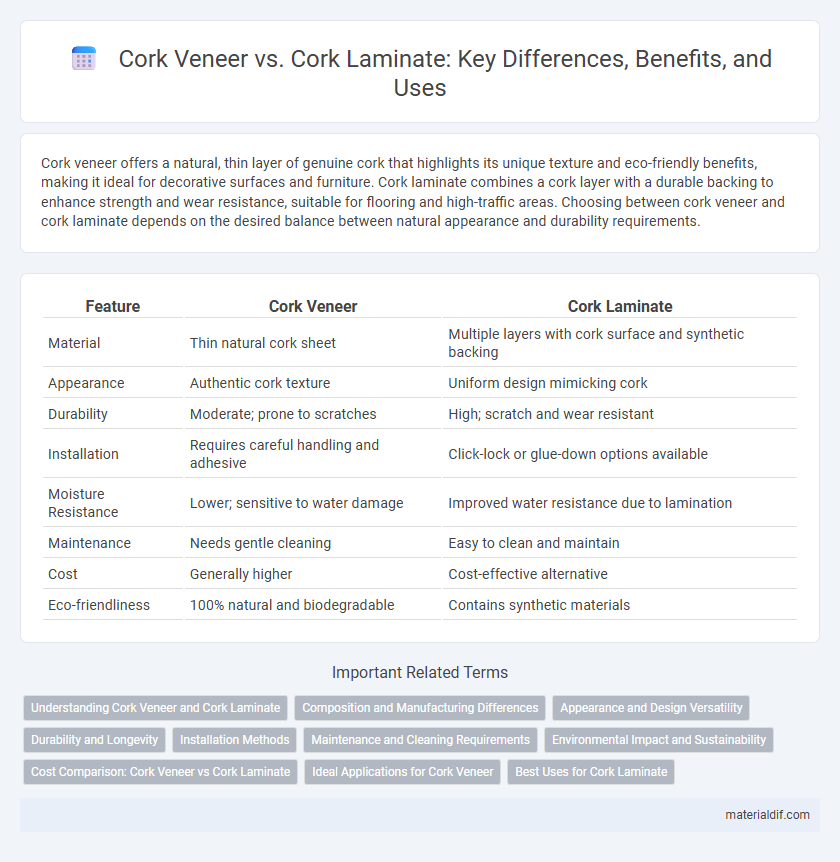

| Feature | Cork Veneer | Cork Laminate |

|---|---|---|

| Material | Thin natural cork sheet | Multiple layers with cork surface and synthetic backing |

| Appearance | Authentic cork texture | Uniform design mimicking cork |

| Durability | Moderate; prone to scratches | High; scratch and wear resistant |

| Installation | Requires careful handling and adhesive | Click-lock or glue-down options available |

| Moisture Resistance | Lower; sensitive to water damage | Improved water resistance due to lamination |

| Maintenance | Needs gentle cleaning | Easy to clean and maintain |

| Cost | Generally higher | Cost-effective alternative |

| Eco-friendliness | 100% natural and biodegradable | Contains synthetic materials |

Understanding Cork Veneer and Cork Laminate

Cork veneer consists of thin slices of natural cork adhered to a substrate, providing an authentic cork texture and appearance ideal for decorative surfaces and furniture. Cork laminate, on the other hand, is made by combining cork granules with adhesives and a protective top layer, offering enhanced durability and water resistance for flooring and wall coverings. Understanding the differences between cork veneer and cork laminate helps in choosing the right product based on aesthetic appeal, wear resistance, and maintenance requirements.

Composition and Manufacturing Differences

Cork veneer consists of thin slices of natural cork adhered to a backing material, preserving the organic texture and breathability of cork. Cork laminate combines a cork layer with multiple resin or melamine layers, enhancing durability and resistance to moisture and wear. The manufacturing process for cork veneer emphasizes gentle slicing and minimal processing, while cork laminate involves heat-pressing and layering to create a robust, engineered surface.

Appearance and Design Versatility

Cork veneer offers a natural, textured appearance with unique grain patterns that enhance design authenticity, while cork laminate provides a smoother, more uniform finish suited for modern aesthetics. The veneer's flexibility allows it to conform to curved surfaces and intricate designs, making it ideal for custom furniture and decorative projects. In contrast, cork laminate excels in durability and ease of maintenance, supporting a wide range of colors and patterns for versatile design applications.

Durability and Longevity

Cork veneer offers natural resilience and can last up to 10-15 years with proper care, but its thin layer makes it more susceptible to dents and scratches compared to cork laminate. Cork laminate combines a thicker cork layer with protective sealing, enhancing its durability and extending its longevity to 20 years or more under regular use. This makes cork laminate a more robust option for high-traffic areas where lasting performance is essential.

Installation Methods

Cork veneer installation involves adhering thin sheets of natural cork directly onto surfaces using specialized adhesives, requiring careful handling to maintain the material's delicate texture. Cork laminate, composed of a cork layer bonded to a durable backing, typically features click-lock or tongue-and-groove systems that enable straightforward floating floor installations without the need for glue. The choice between cork veneer and cork laminate installation methods impacts project duration and skill level, with cork laminate offering quicker installation suited for DIY projects.

Maintenance and Cleaning Requirements

Cork veneer requires gentle cleaning with a soft cloth and mild soap to protect its natural texture, while cork laminate is more resistant to stains and can be cleaned using standard household cleaners without damage. Regular maintenance for cork veneer includes avoiding excessive moisture and direct sunlight to prevent warping, whereas cork laminate offers enhanced durability and easier upkeep in high-traffic areas. Both materials benefit from periodic sealing, but cork laminate typically demands less frequent resealing due to its added protective layer.

Environmental Impact and Sustainability

Cork veneer is made from thin slices of natural cork bark, offering high sustainability due to its renewable harvesting process that doesn't harm the tree, supporting biodiversity and carbon sequestration in Cork's forests. Cork laminate, typically composed of cork particles bonded with synthetic resins, has a higher environmental impact because of the adhesives used, which may release volatile organic compounds (VOCs) and complicate recycling efforts. Choosing cork veneer over laminate enhances environmental benefits by reducing chemical emissions and promoting the sustainable management of Cork's cork oak ecosystems.

Cost Comparison: Cork Veneer vs Cork Laminate

Cork veneer typically costs more than cork laminate due to its natural material quality and craftsmanship involved in its production. Cork laminate offers a more budget-friendly option with a composite backing that reduces expenses while maintaining the aesthetic appeal of cork. Homeowners and designers often choose cork laminate for cost-effective flooring solutions, whereas cork veneer is preferred for premium finishes and durability.

Ideal Applications for Cork Veneer

Cork veneer is ideal for decorative applications where natural texture and flexibility are essential, such as furniture facades, wall panels, and custom cabinetry. Its thin, pliable sheets allow for easy bending and wrapping around curved surfaces, making it perfect for intricate design details and lightweight solutions. Cork veneer's rich, organic appearance enhances interior aesthetics while providing sustainable and eco-friendly qualities.

Best Uses for Cork Laminate

Cork laminate offers superior durability and moisture resistance, making it ideal for high-traffic areas like kitchens, bathrooms, and commercial spaces where wear and tear are common. Its layered construction provides enhanced stability and ease of maintenance compared to natural cork veneer, which is better suited for low-traffic decorative applications such as wall coverings and furniture accents. Cork laminate's versatility and resilience make it the best choice for flooring solutions requiring long-lasting performance with the natural warmth and aesthetic of cork.

Cork Veneer vs Cork Laminate Infographic

materialdif.com

materialdif.com