Boiled cork undergoes a steaming process that enhances its flexibility and makes it easier to shape, making it ideal for pet chew toys and accessories. Raw cork retains its natural texture and fragrance, providing a more natural and slightly rough surface that some pets prefer for gnawing. Choosing between boiled and raw cork depends on the desired durability and sensory experience for your pet's needs.

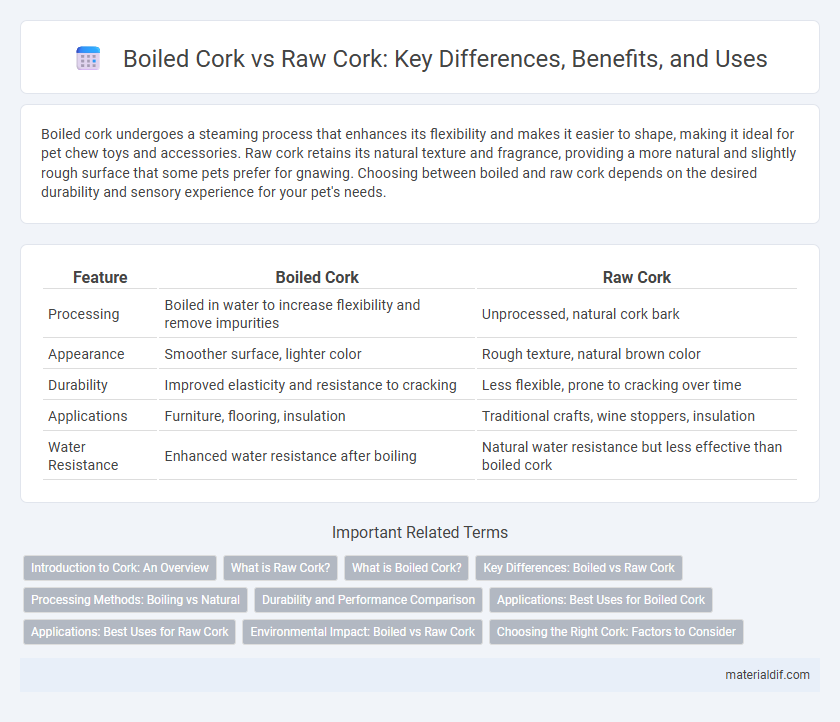

Table of Comparison

| Feature | Boiled Cork | Raw Cork |

|---|---|---|

| Processing | Boiled in water to increase flexibility and remove impurities | Unprocessed, natural cork bark |

| Appearance | Smoother surface, lighter color | Rough texture, natural brown color |

| Durability | Improved elasticity and resistance to cracking | Less flexible, prone to cracking over time |

| Applications | Furniture, flooring, insulation | Traditional crafts, wine stoppers, insulation |

| Water Resistance | Enhanced water resistance after boiling | Natural water resistance but less effective than boiled cork |

Introduction to Cork: An Overview

Boiled cork undergoes thermal treatment to improve flexibility, durability, and resistance to moisture, making it ideal for consumer products like wine stoppers and insulation. Raw cork is harvested directly from cork oak trees without processing, retaining its natural texture and color, commonly used in crafts and flooring. Both forms originate from sustainable cork oak forests primarily found in regions like Portugal, Spain, and Cork County, Ireland, supporting eco-friendly industries.

What is Raw Cork?

Raw cork is the natural, untreated bark harvested directly from the cork oak tree, characterized by its rough texture and irregular surface. Unlike boiled cork, raw cork retains its original moisture content and density, making it more rigid and less flexible. This form of cork is primarily used in traditional applications where natural aesthetics and structural integrity are essential, such as in artisan crafts and certain construction materials.

What is Boiled Cork?

Boiled cork is raw cork that has been immersed in hot water to soften its texture and remove impurities, enhancing its flexibility and making it easier to work with in various applications. This treatment process also helps to improve the cork's insulation properties and durability, making boiled cork ideal for flooring, insulation, and crafts in Cork production. Unlike raw cork, boiled cork exhibits a smoother surface and a more uniform appearance, which contributes to its popularity in both functional and decorative uses.

Key Differences: Boiled vs Raw Cork

Boiled cork undergoes a steaming process that enhances flexibility, making it more pliable and suitable for crafts and insulation, whereas raw cork retains its natural rigidity and rough texture, ideal for structural uses and cork stoppers. The boiling also removes impurities and increases durability in boiled cork, whereas raw cork maintains higher density and natural resistance to moisture due to its untouched state. These differences influence applications significantly, with boiled cork preferred for intricate designs and raw cork favored in traditional wine bottle sealing and flooring.

Processing Methods: Boiling vs Natural

Boiled cork undergoes a heating process where raw cork is submerged in boiling water to remove impurities and increase flexibility, enhancing its durability and compressibility for products like wine stoppers and flooring. Raw cork is harvested directly from the cork oak tree without any boiling treatment, maintaining its natural texture and moisture, which makes it ideal for insulation and certain craft applications. The boiling process also darkens cork's color and reduces tannins, while raw cork preserves its original light tone and organic properties.

Durability and Performance Comparison

Boiled cork exhibits enhanced durability compared to raw cork due to the heat treatment process, which increases its resistance to moisture, mold, and wear. Raw cork maintains a more natural texture but is more prone to cracking and deterioration over time, especially in humid or high-traffic environments. Performance-wise, boiled cork offers improved elasticity and longevity, making it suitable for flooring, insulation, and industrial applications where sustained resilience is critical.

Applications: Best Uses for Boiled Cork

Boiled cork is highly valued in applications requiring flexibility and durability, such as in footwear insoles, gaskets, and fishing rod handles due to its softer texture and improved elasticity compared to raw cork. Its enhanced water resistance makes boiled cork ideal for marine equipment and sports accessories where moisture exposure is frequent. Raw cork, while stiffer and more brittle, is better suited for structural uses like wine stoppers and insulation panels where rigidity is crucial.

Applications: Best Uses for Raw Cork

Raw cork's natural porosity and flexibility make it ideal for acoustic insulation in architectural designs and soundproofing solutions. Its untreated surface retains excellent thermal insulation properties, suitable for sustainable building materials and eco-friendly packaging. In contrast, boiled cork is often preferred for decorative and buoyancy applications due to its smooth texture and enhanced durability.

Environmental Impact: Boiled vs Raw Cork

Boiled cork undergoes a steaming process that reduces waste by making the material more pliable and reusable, lowering environmental impact compared to raw cork, which is less processed and often discarded. The energy consumption in boiling cork is offset by its longer lifespan and lower need for chemical treatments than raw cork. Raw cork harvesting minimally affects the cork oak trees, supporting biodiversity, but boiled cork's enhanced durability promotes sustainable usage and reduces landfill waste.

Choosing the Right Cork: Factors to Consider

Boiled cork offers enhanced flexibility and durability compared to raw cork, making it ideal for applications requiring resilience and moisture resistance. Raw cork maintains its natural texture and is preferred for artisanal crafts and insulation due to its greater porosity and thermal properties. Selecting the right cork depends on the intended use, balancing factors such as flexibility, moisture tolerance, insulation needs, and aesthetic considerations.

Boiled cork vs Raw cork Infographic

materialdif.com

materialdif.com