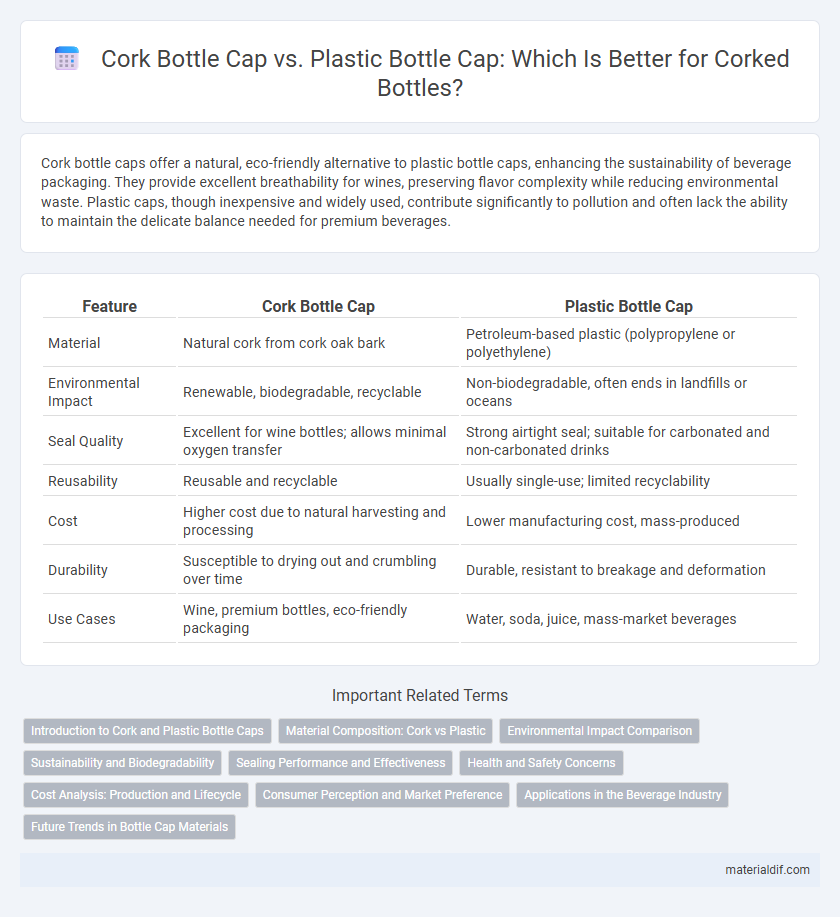

Cork bottle caps offer a natural, eco-friendly alternative to plastic bottle caps, enhancing the sustainability of beverage packaging. They provide excellent breathability for wines, preserving flavor complexity while reducing environmental waste. Plastic caps, though inexpensive and widely used, contribute significantly to pollution and often lack the ability to maintain the delicate balance needed for premium beverages.

Table of Comparison

| Feature | Cork Bottle Cap | Plastic Bottle Cap |

|---|---|---|

| Material | Natural cork from cork oak bark | Petroleum-based plastic (polypropylene or polyethylene) |

| Environmental Impact | Renewable, biodegradable, recyclable | Non-biodegradable, often ends in landfills or oceans |

| Seal Quality | Excellent for wine bottles; allows minimal oxygen transfer | Strong airtight seal; suitable for carbonated and non-carbonated drinks |

| Reusability | Reusable and recyclable | Usually single-use; limited recyclability |

| Cost | Higher cost due to natural harvesting and processing | Lower manufacturing cost, mass-produced |

| Durability | Susceptible to drying out and crumbling over time | Durable, resistant to breakage and deformation |

| Use Cases | Wine, premium bottles, eco-friendly packaging | Water, soda, juice, mass-market beverages |

Introduction to Cork and Plastic Bottle Caps

Cork bottle caps, derived from the bark of the cork oak tree mainly found in the Mediterranean region, offer natural breathability and sustainability benefits compared to plastic bottle caps made from petroleum-based polymers. Cork provides excellent sealing properties ideal for wine bottles, allowing micro-oxygenation which enhances aging, while plastic caps are commonly used for mass-produced beverages due to their low cost and ease of manufacturing. The environmental impact of cork is generally lower since it is biodegradable and renewable, contrasting with the ecological concerns linked to plastic waste and recycling challenges.

Material Composition: Cork vs Plastic

Cork bottle caps are made from the bark of the cork oak tree, a renewable and biodegradable material known for its natural elasticity and impermeability, which effectively preserves the quality of beverages. Plastic bottle caps are typically composed of polyethylene or polypropylene, synthetic polymers derived from fossil fuels, offering durability and a tight seal but posing environmental challenges due to their non-biodegradability. The choice between cork and plastic bottle caps significantly impacts sustainability, with cork promoting eco-friendly practices while plastic contributes to long-term pollution.

Environmental Impact Comparison

Cork bottle caps offer a sustainable alternative to plastic caps, as cork is a natural, biodegradable material harvested from the bark of cork oak trees without harming the tree itself. Plastic bottle caps contribute significantly to environmental pollution due to their petroleum-based composition, slow decomposition rate, and prevalence in marine litter. The renewable nature of cork and its carbon sequestration properties reduce landfill waste and lower the ecological footprint compared to the synthetic, non-renewable plastics used in conventional bottle caps.

Sustainability and Biodegradability

Cork bottle caps offer superior sustainability due to their renewable natural cork material, which is harvested without harming trees, promoting forest health and carbon sequestration. Unlike plastic bottle caps, which are derived from fossil fuels and contribute to long-lasting pollution, cork caps are fully biodegradable and compostable, breaking down naturally in the environment within months. This eco-friendly profile makes cork caps a preferable choice for reducing landfill waste and minimizing environmental impact in packaging.

Sealing Performance and Effectiveness

Cork bottle caps provide superior sealing performance due to their natural elasticity, which allows them to expand and contract with temperature changes, maintaining an airtight seal that protects the contents from oxidation. In contrast, plastic bottle caps rely on threaded designs and gaskets, which can degrade over time and may not provide consistent effectiveness under varying pressure conditions. Studies show cork caps reduce gas exchange rates by up to 70%, enhancing product shelf life compared to plastic caps that are prone to micro-leakage.

Health and Safety Concerns

Cork bottle caps are made from natural, biodegradable materials that reduce the risk of chemical leaching and are less likely to harbor harmful bacteria compared to plastic caps. Plastic bottle caps often contain BPA and other toxins that can contaminate beverages, posing long-term health risks, especially when exposed to heat. Choosing cork caps enhances safety by minimizing exposure to synthetic chemicals and supporting a toxin-free consumption experience.

Cost Analysis: Production and Lifecycle

Cork bottle caps generally have higher upfront production costs due to the natural harvesting and processing of cork material, whereas plastic bottle caps benefit from lower manufacturing expenses and mass production efficiency. Over the lifecycle, cork caps offer superior environmental benefits with biodegradability and reduced carbon footprint, potentially lowering long-term waste management costs compared to plastic caps that contribute to persistent pollution. Cost analysis reveals cork caps favor sustainability investments, while plastic caps dominate in immediate cost savings and scalability.

Consumer Perception and Market Preference

Consumers in Cork increasingly favor cork bottle caps for their sustainability and premium image, associating them with natural, eco-friendly products. Market preference in Cork shows higher demand for cork caps in artisanal and organic beverages, reflecting a growing trend towards environmental responsibility and product authenticity. Plastic bottle caps remain prevalent in mass-produced beverages due to cost efficiency and convenience but face rising criticism from Cork consumers concerned about plastic waste.

Applications in the Beverage Industry

Cork bottle caps, known for their natural elasticity and breathability, are predominantly used in wine bottles, enhancing aging by allowing micro-oxygenation. Plastic bottle caps, favored in soft drinks and water bottles, provide airtight sealing and are cost-effective for mass production and quick consumption products. The beverage industry relies on cork caps for premium wines and craft brews, while plastic caps dominate in soda, juice, and mineral water packaging due to their durability and ease of use.

Future Trends in Bottle Cap Materials

Cork bottle caps continue to gain traction as eco-friendly alternatives due to their biodegradability and renewable sourcing, aligning with global sustainability targets. Innovations in composite materials and biodegradable polymers are pushing plastic bottle caps toward enhanced recyclability and reduced environmental footprints. Future trends indicate a growing consumer preference and regulatory support for materials that balance performance with ecological impact, making cork and advanced bioplastics key players in bottle cap evolution.

Cork Bottle Cap vs Plastic Bottle Cap Infographic

materialdif.com

materialdif.com