Cork veneer offers a lightweight, flexible option ideal for furniture and wall coverings, providing the natural texture and sustainability of cork with easier installation. Cork block, being denser and thicker, excels in insulation and soundproofing applications, delivering superior durability and impact resistance for flooring and construction projects. Choosing between cork veneer and cork block depends on the specific requirements for aesthetics, performance, and structural strength in your Cork-based design.

Table of Comparison

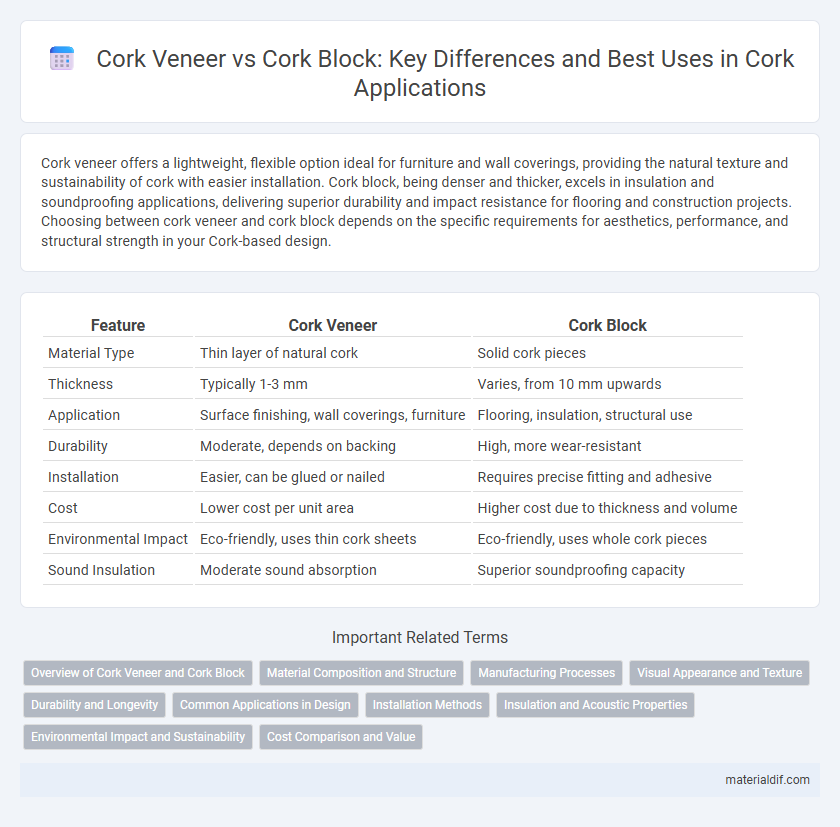

| Feature | Cork Veneer | Cork Block |

|---|---|---|

| Material Type | Thin layer of natural cork | Solid cork pieces |

| Thickness | Typically 1-3 mm | Varies, from 10 mm upwards |

| Application | Surface finishing, wall coverings, furniture | Flooring, insulation, structural use |

| Durability | Moderate, depends on backing | High, more wear-resistant |

| Installation | Easier, can be glued or nailed | Requires precise fitting and adhesive |

| Cost | Lower cost per unit area | Higher cost due to thickness and volume |

| Environmental Impact | Eco-friendly, uses thin cork sheets | Eco-friendly, uses whole cork pieces |

| Sound Insulation | Moderate sound absorption | Superior soundproofing capacity |

Overview of Cork Veneer and Cork Block

Cork veneer is a thin layer of cork material sliced from the outer bark, prized for its lightweight, flexibility, and ease of application on surfaces like furniture and wall panels. Cork block, by contrast, is a thicker, solid piece typically used for flooring and soundproofing due to its durability, compression resistance, and insulating properties. Both types provide the natural benefits of cork, including sustainability, moisture resistance, and thermal insulation, but their applications vary according to thickness and structural use.

Material Composition and Structure

Cork veneer consists of thin sheets of cork harvested from the bark of the cork oak tree, maintaining a flexible and lightweight structure ideal for surface applications. In contrast, cork blocks are composed of compressed granules of cork, forming a dense and solid material with greater durability and insulating properties. The natural cellular structure of both preserves cork's elasticity and thermal performance, but the block's compact composition offers enhanced mechanical strength compared to the veneer's layered format.

Manufacturing Processes

Cork veneer is produced by slicing thin sheets from the outer layer of cork bark, allowing for efficient use of raw material and minimal waste. Cork block manufacturing involves compressing granulated cork with adhesives under heat and pressure, creating dense, uniform panels suitable for insulation and flooring. The veneer process preserves the natural texture and pattern, whereas block manufacturing emphasizes structural integrity and versatility.

Visual Appearance and Texture

Cork veneer offers a thin, smooth surface with a consistent grain pattern that enhances visual appeal while maintaining flexibility for various design applications. Cork block, being thicker and denser, presents a more natural, textured look with pronounced variances in pattern and depth, providing a robust tactile experience. The choice between veneer and block cork depends on whether a refined, uniform appearance or a rugged, organic texture is desired for a project in Cork interiors.

Durability and Longevity

Cork veneer offers flexibility and aesthetic appeal but generally has lower durability compared to cork block, which is denser and more resistant to wear and impact. Cork block's solid composition ensures superior longevity, making it ideal for heavy-use applications like flooring and furniture. Choosing cork block enhances durability, maintaining structural integrity over time despite frequent use.

Common Applications in Design

Cork veneer is widely used in furniture design and interior surfaces due to its thin, flexible nature, making it ideal for decorative panels, wall coverings, and lightweight cabinetry. Cork blocks, being thicker and more durable, find common applications in flooring, soundproofing, and insulation where structural integrity and resilience are critical. Designers often choose veneer for aesthetic enhancements and blocks for functional purposes in sustainable architecture and eco-friendly product development.

Installation Methods

Cork veneer installation typically involves adhesive application directly to the substrate, allowing for a smooth, thin layer that enhances flexibility and reduces material costs. Cork block installation requires precise alignment and often the use of mechanical fasteners or specialized adhesives to secure thicker, heavier sections, offering superior durability and insulation. Proper surface preparation and moisture control are crucial for both methods to ensure long-lasting adhesion and performance.

Insulation and Acoustic Properties

Cork veneer offers excellent thermal insulation with a thin, flexible layer ideal for enhancing energy efficiency in walls and furniture, while cork block provides superior acoustic absorption due to its dense, solid structure, effectively reducing sound transmission in flooring and ceilings. The cellular composition of cork block improves impact noise insulation, making it a preferred choice for soundproofing applications, whereas cork veneer is more suited for subtle thermal insulation and surface finishes. Both materials retain natural moisture resistance and durability, but their distinct thickness and density directly influence their performance in insulating and acoustic roles.

Environmental Impact and Sustainability

Cork veneer offers a significantly lower environmental impact compared to cork blocks due to its efficient use of raw material, resulting in reduced harvesting of cork oak trees. The production of cork veneer requires less energy and generates minimal waste, promoting sustainability in both manufacturing and end-use. Cork blocks, while durable, involve larger quantities of cork and more intensive processing, which can increase carbon footprint and resource consumption.

Cost Comparison and Value

Cork veneer is generally more cost-effective than cork block due to its thinner profile and lower material usage, making it ideal for budget-friendly surface applications. Cork block, while more expensive, offers greater durability and insulation value, suitable for insulation or structural purposes where longevity is essential. Evaluating the balance between initial investment and long-term benefits is crucial when choosing between cork veneer and cork block for specific projects in Cork.

cork veneer vs cork block Infographic

materialdif.com

materialdif.com