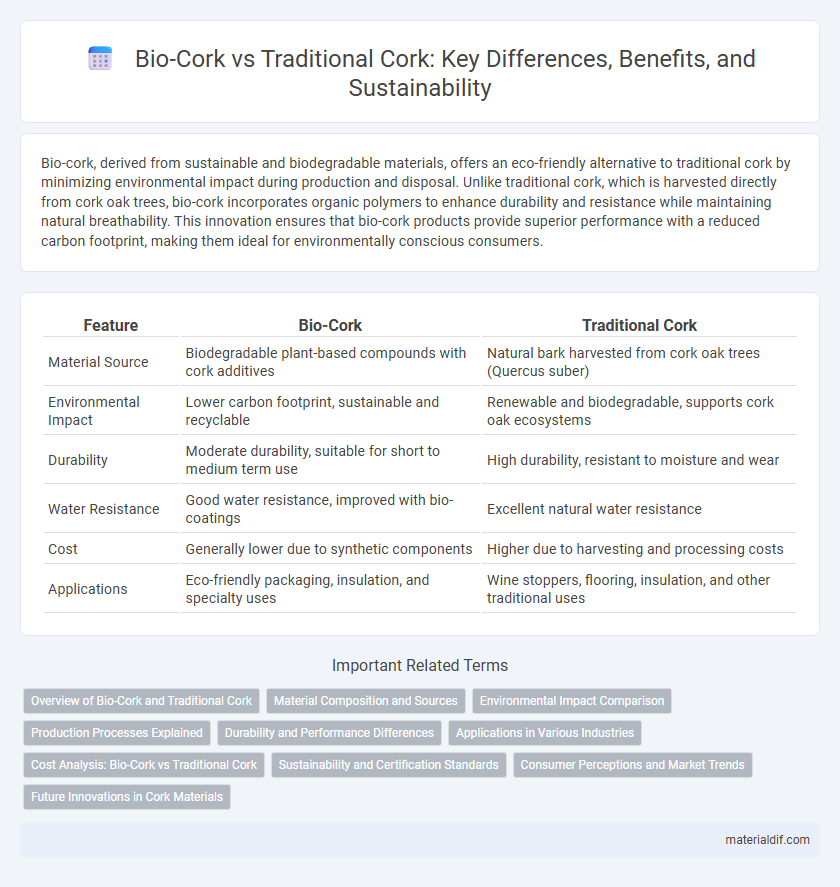

Bio-cork, derived from sustainable and biodegradable materials, offers an eco-friendly alternative to traditional cork by minimizing environmental impact during production and disposal. Unlike traditional cork, which is harvested directly from cork oak trees, bio-cork incorporates organic polymers to enhance durability and resistance while maintaining natural breathability. This innovation ensures that bio-cork products provide superior performance with a reduced carbon footprint, making them ideal for environmentally conscious consumers.

Table of Comparison

| Feature | Bio-Cork | Traditional Cork |

|---|---|---|

| Material Source | Biodegradable plant-based compounds with cork additives | Natural bark harvested from cork oak trees (Quercus suber) |

| Environmental Impact | Lower carbon footprint, sustainable and recyclable | Renewable and biodegradable, supports cork oak ecosystems |

| Durability | Moderate durability, suitable for short to medium term use | High durability, resistant to moisture and wear |

| Water Resistance | Good water resistance, improved with bio-coatings | Excellent natural water resistance |

| Cost | Generally lower due to synthetic components | Higher due to harvesting and processing costs |

| Applications | Eco-friendly packaging, insulation, and specialty uses | Wine stoppers, flooring, insulation, and other traditional uses |

Overview of Bio-Cork and Traditional Cork

Bio-cork refers to a sustainable cork material derived from natural cork oak bark, enhanced with bio-based binders to improve flexibility and durability while maintaining its eco-friendly properties. Traditional cork is harvested directly from cork oak trees, prized for its natural elasticity, insulation, and lightweight characteristics, commonly used in bottle stoppers, flooring, and insulation. Both materials emphasize renewable sourcing, but bio-cork integrates modern bio-polymers to expand application versatility and reduce environmental impact.

Material Composition and Sources

Bio-cork is made from renewable cork waste combined with natural resins, enhancing sustainability by reducing reliance on virgin cork harvested from cork oak trees primarily found in Portugal and Spain. Traditional cork consists solely of natural cork bark, harvested without damaging the tree, maintaining a unique cellular structure that provides elasticity and waterproofing. The composite material in bio-cork offers improved durability and consistent quality while lowering environmental impact compared to the pure natural composition of traditional cork.

Environmental Impact Comparison

Bio-cork, produced using sustainable, organic processes, significantly reduces carbon emissions compared to traditional cork, which relies on conventional harvesting methods. Traditional cork harvesting can disrupt local ecosystems and generate more industrial waste, whereas bio-cork promotes biodiversity by preserving cork oak forests and minimizing chemical use. Life cycle assessments reveal bio-cork's lower environmental footprint, making it a greener choice in cork production.

Production Processes Explained

Bio-cork production involves using natural cork granules bonded with sustainable, food-grade adhesives, reducing chemical usage compared to traditional cork processing, which relies on manual harvesting and minimal treatment of bark sheets. Unlike traditional cork, which undergoes a prolonged seasoning and boiling phase to enhance elasticity, bio-cork utilizes a binding process that allows faster production with less energy consumption. The eco-friendly bio-cork manufacturing reduces waste by utilizing cork residues, promoting circular economy principles within cork industries in Portugal and Spain.

Durability and Performance Differences

Bio-cork offers enhanced durability compared to traditional cork due to its renewable resin binders that improve resistance to moisture and wear. Traditional cork, while naturally resilient and flexible, tends to degrade faster under frequent use and exposure to humidity. Performance tests reveal bio-cork maintains structural integrity longer in flooring and insulation applications, making it a superior choice for longevity and sustainable building solutions in Cork.

Applications in Various Industries

Bio-cork, derived from sustainable and eco-friendly processes, offers enhanced durability and water resistance compared to traditional cork, making it ideal for applications in construction, automotive, and fashion industries. Its lightweight yet robust properties allow for innovative usage in sound insulation, flooring, and footwear, promoting environmental responsibility without compromising performance. Industries seeking sustainable material alternatives increasingly favor bio-cork for its renewable sourcing and versatility across diverse manufacturing processes.

Cost Analysis: Bio-Cork vs Traditional Cork

Bio-cork production costs typically exceed those of traditional cork due to advanced processing technologies and sustainable raw material sourcing. Traditional cork benefits from centuries of established harvesting methods and supply chains, resulting in lower manufacturing expenses. However, the rising demand for eco-friendly products may drive economies of scale that could decrease bio-cork costs in the near future.

Sustainability and Certification Standards

Bio-cork stands out for its enhanced sustainability, as it is produced using 100% natural waste materials without synthetic additives, reducing environmental impact compared to traditional cork harvesting. Both bio-cork and traditional cork comply with stringent certification standards such as FSC (Forest Stewardship Council) and PEFC (Programme for the Endorsement of Forest Certification), ensuring responsible forest management. The eco-friendly manufacturing process of bio-cork supports carbon neutrality initiatives and promotes circular economy principles within the cork industry.

Consumer Perceptions and Market Trends

Bio-cork, derived from sustainable and biodegradable materials, is increasingly favored by eco-conscious consumers seeking environmentally friendly alternatives to traditional cork harvested from cork oak trees. Market trends indicate a rising demand for bio-cork products in sectors like footwear, packaging, and construction due to their reduced environmental impact and comparable durability. Consumer perception surveys reveal that transparency about sourcing and manufacturing processes significantly enhances trust and preference for bio-cork over conventional cork options.

Future Innovations in Cork Materials

Bio-cork, derived from sustainable and biodegradable plant-based polymers, offers a groundbreaking alternative to traditional cork harvested from the Quercus suber tree in the Mediterranean. Future innovations in cork materials emphasize enhanced durability, water resistance, and eco-friendly processing techniques, aiming to reduce environmental impact while maintaining cork's natural insulation and lightweight properties. Research into bio-cork composites and nanotechnology integration promises to revolutionize applications in construction, fashion, and packaging by combining sustainability with advanced performance characteristics.

bio-cork vs traditional cork Infographic

materialdif.com

materialdif.com