Cork tapping involves carefully removing the bark from cork oak trees by hand, preserving the tree's health and ensuring sustainable harvesting every 9 to 12 years. Mechanical extraction uses machinery to expedite the process but can risk damaging the tree and reducing future cork quality. Traditional tapping remains the preferred method for premium cork production due to its balance of efficiency and environmental stewardship.

Table of Comparison

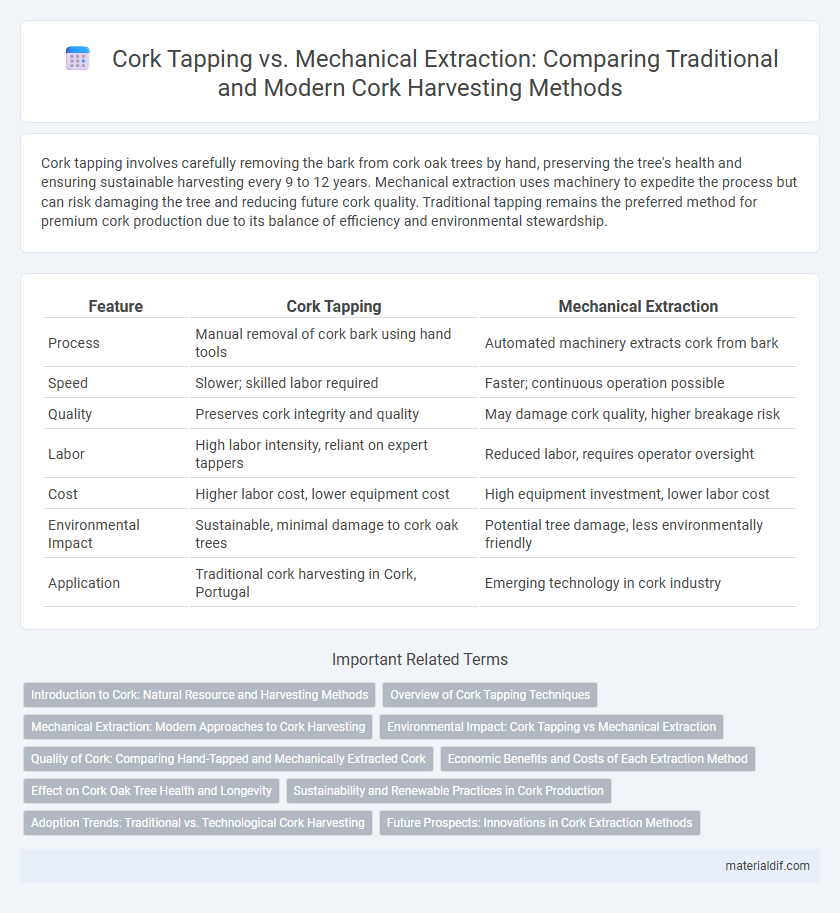

| Feature | Cork Tapping | Mechanical Extraction |

|---|---|---|

| Process | Manual removal of cork bark using hand tools | Automated machinery extracts cork from bark |

| Speed | Slower; skilled labor required | Faster; continuous operation possible |

| Quality | Preserves cork integrity and quality | May damage cork quality, higher breakage risk |

| Labor | High labor intensity, reliant on expert tappers | Reduced labor, requires operator oversight |

| Cost | Higher labor cost, lower equipment cost | High equipment investment, lower labor cost |

| Environmental Impact | Sustainable, minimal damage to cork oak trees | Potential tree damage, less environmentally friendly |

| Application | Traditional cork harvesting in Cork, Portugal | Emerging technology in cork industry |

Introduction to Cork: Natural Resource and Harvesting Methods

Cork, harvested primarily from the Quercus suber tree native to the Mediterranean region, is a sustainable natural resource prized for its elasticity and impermeability. Traditional cork tapping involves carefully stripping the outer bark by hand every 9 to 12 years, preserving the tree's health and ensuring continuous growth. Mechanical extraction methods, while faster, risk damaging the tree, potentially reducing cork quality and lifespan compared to manual harvesting techniques.

Overview of Cork Tapping Techniques

Traditional cork tapping involves manually scoring and extracting cork bark from Quercus suber trees using specialized hand tools, preserving tree health and ensuring high-quality cork planks. Mechanical extraction employs hydraulic or pneumatic devices to increase efficiency, but requires careful calibration to prevent damage to the bark. Both techniques focus on sustainable harvesting practices to balance productivity with the longevity of cork oak forests.

Mechanical Extraction: Modern Approaches to Cork Harvesting

Mechanical extraction technologies in cork harvesting have revolutionized the traditional tapping process by enhancing efficiency and reducing labor intensity. Advanced machinery precisely removes cork with minimal damage to the oak trees (Quercus suber), preserving their health and ensuring sustainable production cycles. Innovations like automated cork peelers and hydraulic systems optimize yield quality and speed, supporting the growing global demand for cork products.

Environmental Impact: Cork Tapping vs Mechanical Extraction

Cork tapping involves carefully harvesting the bark from cork oak trees without harming them, allowing the trees to regenerate over several years, which promotes carbon sequestration and biodiversity conservation. Mechanical extraction, often used in synthetic cork production, relies on petroleum-based materials and energy-intensive manufacturing processes that contribute to higher carbon emissions and environmental degradation. Sustainable cork harvesting supports circular economy principles by utilizing a renewable natural resource with minimal ecological footprint.

Quality of Cork: Comparing Hand-Tapped and Mechanically Extracted Cork

Hand-tapped cork preserves the cellular structure, resulting in higher quality cork that offers superior elasticity and fewer defects, essential for premium wine stoppers. Mechanical extraction often damages the cork's integrity, causing lower density and increased permeability, which can compromise the seal and affect wine preservation. Studies indicate that hand-tapped cork maintains better physical and chemical properties, making it the preferred choice for top-tier cork producers.

Economic Benefits and Costs of Each Extraction Method

Cork tapping preserves the economic value of cork forests by enabling sustainable harvests every 9-12 years, supporting local employment and high market prices due to natural, premium-quality cork products. Mechanical extraction, while increasing yield and reducing labor costs, risks damaging cork trees, leading to long-term declines in cork quality and forest productivity, which can undermine regional economies reliant on cork harvesting. Investment in sustainable tapping methods balances immediate economic benefits with the preservation of cork ecosystems critical for ongoing revenue.

Effect on Cork Oak Tree Health and Longevity

Traditional cork tapping preserves the health and longevity of cork oak trees by carefully removing the bark without damaging the tree's vital tissues, allowing it to regenerate over time. Mechanical extraction methods can cause deeper wounds and structural harm, increasing vulnerability to diseases and reducing the tree's lifespan. Sustainable tapping practices promote ecosystem balance and ensure the long-term productivity of cork oak forests.

Sustainability and Renewable Practices in Cork Production

Cork tapping remains a highly sustainable practice, as it involves harvesting bark without harming cork oak trees, allowing regrowth and carbon sequestration over time. Mechanical extraction methods, while increasing efficiency, often risk damaging the trees and reducing long-term cork yield sustainability. Emphasizing traditional cork tapping supports renewable cork production, biodiversity preservation, and the ecological balance of cork oak forests.

Adoption Trends: Traditional vs. Technological Cork Harvesting

Cork tapping remains the predominant method in regions like Portugal and Spain, where skilled labor and traditional practices sustain its widespread adoption, representing over 80% of cork harvesting techniques. Mechanical extraction technologies are gradually gaining traction, with vineyards utilizing automated cork removal systems to increase efficiency and reduce labor costs, especially in new cork oak plantations. Market data shows a steady rise in mechanized cork harvesting, with adoption rates expected to grow at an annual rate of 5-7% over the next decade due to advancements in extraction machinery and sustainable forestry management practices.

Future Prospects: Innovations in Cork Extraction Methods

Innovations in cork extraction methods are leading to more sustainable and efficient harvesting processes that preserve the integrity of the Cork oak trees in regions like southern Europe. Advanced mechanical extraction technologies, integrated with precise sensor data, reduce damage to bark and improve yield quality while minimizing environmental impact. The future of cork tapping combines traditional expertise with cutting-edge automation, promising enhanced productivity and long-term ecosystem health in cork-producing areas.

cork tapping vs mechanical extraction Infographic

materialdif.com

materialdif.com