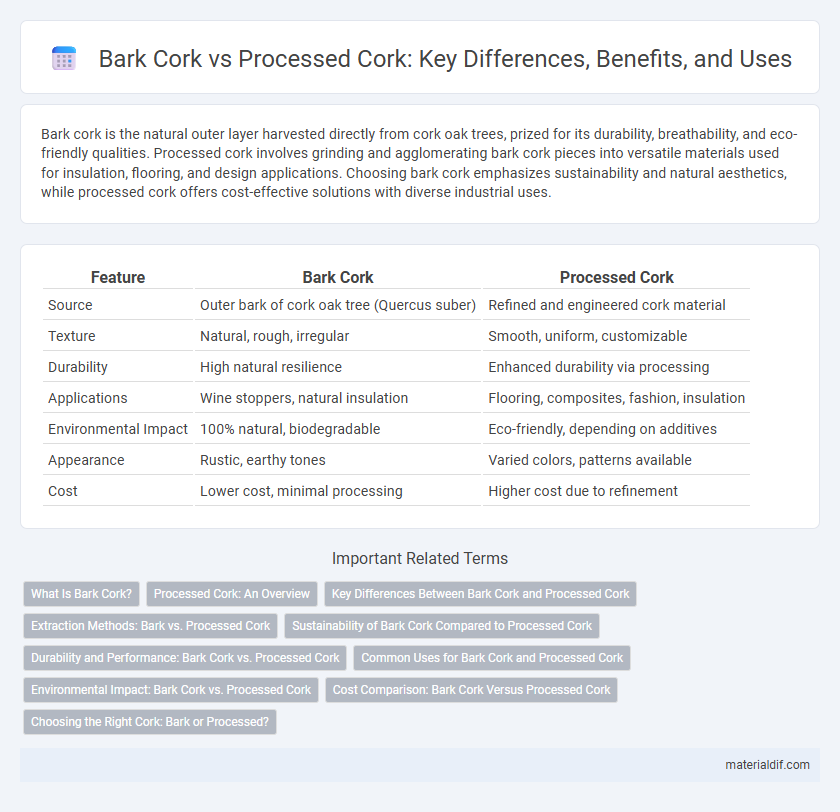

Bark cork is the natural outer layer harvested directly from cork oak trees, prized for its durability, breathability, and eco-friendly qualities. Processed cork involves grinding and agglomerating bark cork pieces into versatile materials used for insulation, flooring, and design applications. Choosing bark cork emphasizes sustainability and natural aesthetics, while processed cork offers cost-effective solutions with diverse industrial uses.

Table of Comparison

| Feature | Bark Cork | Processed Cork |

|---|---|---|

| Source | Outer bark of cork oak tree (Quercus suber) | Refined and engineered cork material |

| Texture | Natural, rough, irregular | Smooth, uniform, customizable |

| Durability | High natural resilience | Enhanced durability via processing |

| Applications | Wine stoppers, natural insulation | Flooring, composites, fashion, insulation |

| Environmental Impact | 100% natural, biodegradable | Eco-friendly, depending on additives |

| Appearance | Rustic, earthy tones | Varied colors, patterns available |

| Cost | Lower cost, minimal processing | Higher cost due to refinement |

What Is Bark Cork?

Bark cork refers to the natural outer bark harvested from cork oak trees, primarily found in the Mediterranean region, especially Portugal and Spain. It is prized for its lightweight, buoyant, and elastic properties, making it an ideal raw material for sustainable products like wine stoppers, flooring, and insulation. Unlike processed cork, which undergoes grinding, binding, and reshaping, bark cork maintains its natural cellular structure, providing superior durability and thermal insulation.

Processed Cork: An Overview

Processed cork is derived from natural cork bark through a series of industrial treatments that enhance its durability and versatility. This material undergoes grinding, heating, and binding to create products such as cork flooring, insulation panels, and composite cork items. Its engineered properties allow for improved resilience, moisture resistance, and consistent quality compared to raw bark cork.

Key Differences Between Bark Cork and Processed Cork

Bark cork is harvested directly from the cork oak tree's outer bark, maintaining its natural cellular structure and providing superior elasticity, breathability, and environmental sustainability. Processed cork undergoes industrial treatments such as grinding, heating, and binding, resulting in a composite material with varied density and reduced natural resilience. Key differences include the origin of material, preservation of natural properties, and versatility in applications, with bark cork preferred for premium products and processed cork used in mass production and insulation.

Extraction Methods: Bark vs. Processed Cork

Extraction methods for bark cork involve carefully stripping the outer bark from mature cork oak trees without damaging the inner layers, allowing the tree to regenerate its bark sustainably over time. Processed cork, however, undergoes mechanical grinding, boiling, and molding after harvesting to create agglomerated cork products with varied densities and uses. The natural, intact bark cork retains its cellular structure, providing superior insulation and elasticity compared to mechanically processed cork materials.

Sustainability of Bark Cork Compared to Processed Cork

Bark cork, harvested from the outer layer of cork oak trees without cutting the tree down, offers a highly sustainable alternative to processed cork, which often involves energy-intensive treatments and adhesives. The natural harvesting cycle of bark cork supports biodiversity and carbon sequestration by preserving cork oak forests, a critical ecosystem in Mediterranean regions. In contrast, processed cork production can contribute to higher carbon emissions and resource consumption, making bark cork a greener choice for eco-conscious consumers and industries.

Durability and Performance: Bark Cork vs. Processed Cork

Bark cork, harvested directly from the outer layer of cork oak trees, retains its natural cellular structure, offering superior durability and resilience under pressure compared to processed cork. Processed cork, often ground and reconstituted with adhesives, may exhibit reduced elasticity and can degrade faster when exposed to moisture and heavy wear. The inherent density and intact grain of bark cork contribute to better performance in applications requiring long-lasting insulation, cushioning, and moisture resistance.

Common Uses for Bark Cork and Processed Cork

Bark cork, harvested directly from the cork oak tree, is commonly used for wine stoppers, flooring, and bulletin boards due to its natural elasticity and moisture resistance. Processed cork, created by agglomerating cork granules, finds widespread application in insulation panels, gaskets, and automotive components where customizable shapes and enhanced durability are required. Both forms contribute to sustainable material solutions, with bark cork favored in traditional crafts and processed cork suited for industrial uses.

Environmental Impact: Bark Cork vs. Processed Cork

Bark cork, harvested directly from the outer layer of cork oak trees, offers a sustainable and eco-friendly option due to its natural regeneration process that does not harm the tree, promoting forest health and carbon sequestration. Processed cork involves industrial treatments and chemical additives that increase its environmental footprint through higher energy consumption and potential pollutants during manufacturing. Choosing bark cork supports biodiversity, reduces waste, and minimizes carbon emissions compared to processed cork products.

Cost Comparison: Bark Cork Versus Processed Cork

Bark cork, harvested directly from cork oak trees, generally incurs higher upfront costs due to sustainable extraction methods and limited supply. Processed cork, produced through grinding and reconstituting bark cork, offers a more affordable alternative with consistent quality and versatile applications. Cost efficiency of processed cork makes it preferable for large-scale industrial use, while bark cork remains premium for luxury and ecological products.

Choosing the Right Cork: Bark or Processed?

Bark cork, harvested directly from the Quercus suber tree, offers natural durability and eco-friendly qualities, making it ideal for sustainable products. Processed cork, treated and refined for uniformity and enhanced physical properties, suits applications requiring precise dimensions and improved resistance to moisture. Selecting between bark cork and processed cork depends on the intended use, balancing natural texture and environmental impact against performance and consistency.

bark cork vs processed cork Infographic

materialdif.com

materialdif.com