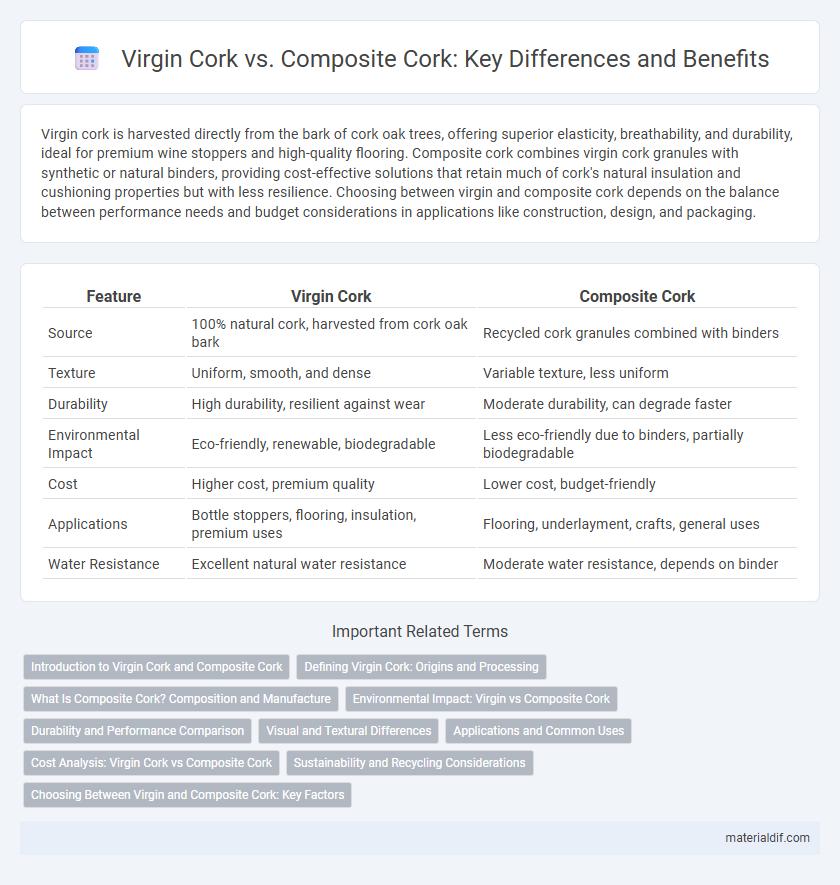

Virgin cork is harvested directly from the bark of cork oak trees, offering superior elasticity, breathability, and durability, ideal for premium wine stoppers and high-quality flooring. Composite cork combines virgin cork granules with synthetic or natural binders, providing cost-effective solutions that retain much of cork's natural insulation and cushioning properties but with less resilience. Choosing between virgin and composite cork depends on the balance between performance needs and budget considerations in applications like construction, design, and packaging.

Table of Comparison

| Feature | Virgin Cork | Composite Cork |

|---|---|---|

| Source | 100% natural cork, harvested from cork oak bark | Recycled cork granules combined with binders |

| Texture | Uniform, smooth, and dense | Variable texture, less uniform |

| Durability | High durability, resilient against wear | Moderate durability, can degrade faster |

| Environmental Impact | Eco-friendly, renewable, biodegradable | Less eco-friendly due to binders, partially biodegradable |

| Cost | Higher cost, premium quality | Lower cost, budget-friendly |

| Applications | Bottle stoppers, flooring, insulation, premium uses | Flooring, underlayment, crafts, general uses |

| Water Resistance | Excellent natural water resistance | Moderate water resistance, depends on binder |

Introduction to Virgin Cork and Composite Cork

Virgin cork is harvested directly from the bark of cork oak trees without any prior processing, ensuring a natural, pure material prized for its elasticity, durability, and sustainability in applications like wine stoppers and insulation. Composite cork, on the other hand, is manufactured by recycling cork materials and binding them with adhesives, offering a cost-effective and eco-friendly alternative while maintaining similar functional properties. The choice between virgin and composite cork depends on the desired balance of natural quality, environmental impact, and application requirements.

Defining Virgin Cork: Origins and Processing

Virgin cork is harvested directly from the bark of cork oak trees, primarily found in Mediterranean regions such as Portugal and Spain, ensuring its natural origin and sustainability. The processing involves careful stripping of the cork without harming the tree, followed by drying, boiling, and flattening to create premium, durable cork products. Its natural cellular structure provides superior elasticity and impermeability compared to composite cork, which is made from agglomerated cork particles combined with binders.

What Is Composite Cork? Composition and Manufacture

Composite cork consists of natural cork granules combined with synthetic binders, creating a material that maintains cork's elasticity and lightweight properties while enhancing durability and flexibility. Manufactured by compressing and curing the mixture under heat and pressure, composite cork is engineered to provide consistent density and improved resistance to moisture and wear. This hybrid structure makes it ideal for applications requiring both the natural benefits of cork and the strength of engineered materials.

Environmental Impact: Virgin vs Composite Cork

Virgin cork is harvested directly from the bark of cork oak trees, promoting sustainable forestry and biodiversity by allowing trees to regenerate naturally without harm. Composite cork, made from recycled cork granules bound with adhesives, reduces raw material usage and minimizes waste but may involve energy-intensive processing and potential off-gassing from binders. Assessing environmental impact, virgin cork supports carbon sequestration and ecosystem health, while composite cork emphasizes waste reduction and circular economy principles, making both options viable depending on specific sustainability priorities.

Durability and Performance Comparison

Virgin cork, harvested directly from natural cork oak trees, offers superior durability and elasticity, making it highly resistant to wear and maintaining its structural integrity over time. Composite cork combines natural cork granules with synthetic binders, which can enhance moisture resistance but often sacrifices some elasticity and long-term resilience. Virgin cork typically outperforms composite cork in applications requiring sustained compressive strength and repeated flexibility, ensuring longer-lasting performance in flooring and insulation.

Visual and Textural Differences

Virgin cork boasts a natural, uniform grain pattern with a smooth texture that highlights its pure cork composition, creating a visually consistent and tactilely soft surface. Composite cork, made from recycled cork pieces bonded together, exhibits a varied, speckled appearance with a rougher, more irregular texture due to its mixed cork fragments. These visual and textural differences impact the overall aesthetic and feel, making virgin cork preferred for premium applications demanding natural beauty and consistent touch.

Applications and Common Uses

Virgin cork, harvested directly from the cork oak tree, is commonly used in wine stoppers, insulation panels, and flooring due to its natural elasticity, moisture resistance, and durability. Composite cork, made from agglomerated cork granules bound with adhesives, is favored for applications in bulletin boards, underlayment in construction, and craft materials because of its cost-effectiveness and versatility. Both materials are widely utilized in industries ranging from beverage sealing to interior design, with virgin cork preferred for premium and natural uses, while composite cork suits budget-conscious and decorative purposes.

Cost Analysis: Virgin Cork vs Composite Cork

Virgin cork typically commands a higher price due to its natural harvesting process and superior quality, which translates to increased durability and performance in applications such as wine stoppers. Composite cork, made from cork granules mixed with binders, offers a cost-effective alternative by utilizing cork waste and reducing raw material expenses, though it may compromise on elasticity and longevity. Businesses must weigh initial savings from composite cork against potential replacement costs and consumer perception when selecting the optimal cork type for their products.

Sustainability and Recycling Considerations

Virgin cork, harvested from the bark of living cork oak trees without harming them, is highly sustainable due to its renewable nature and carbon sequestration benefits. Composite cork, made from byproducts and cork dust combined with binders, supports recycling efforts by utilizing waste materials but may have a reduced environmental footprint depending on the binder composition. Both types contribute to sustainable cork use, yet virgin cork remains superior in natural renewability and ecosystem preservation.

Choosing Between Virgin and Composite Cork: Key Factors

Virgin cork is sourced from the bark of cork oak trees and offers superior elasticity, durability, and natural insulation properties compared to composite cork, which combines cork granules with synthetic binders. Key factors in choosing between virgin and composite cork include application requirements such as impact resistance, moisture resistance, and thermal performance, where virgin cork typically excels in eco-friendliness and long-term resilience. Budget constraints also influence the decision, as composite cork is generally more cost-effective but may sacrifice some natural benefits inherent to virgin cork.

Virgin cork vs Composite cork Infographic

materialdif.com

materialdif.com