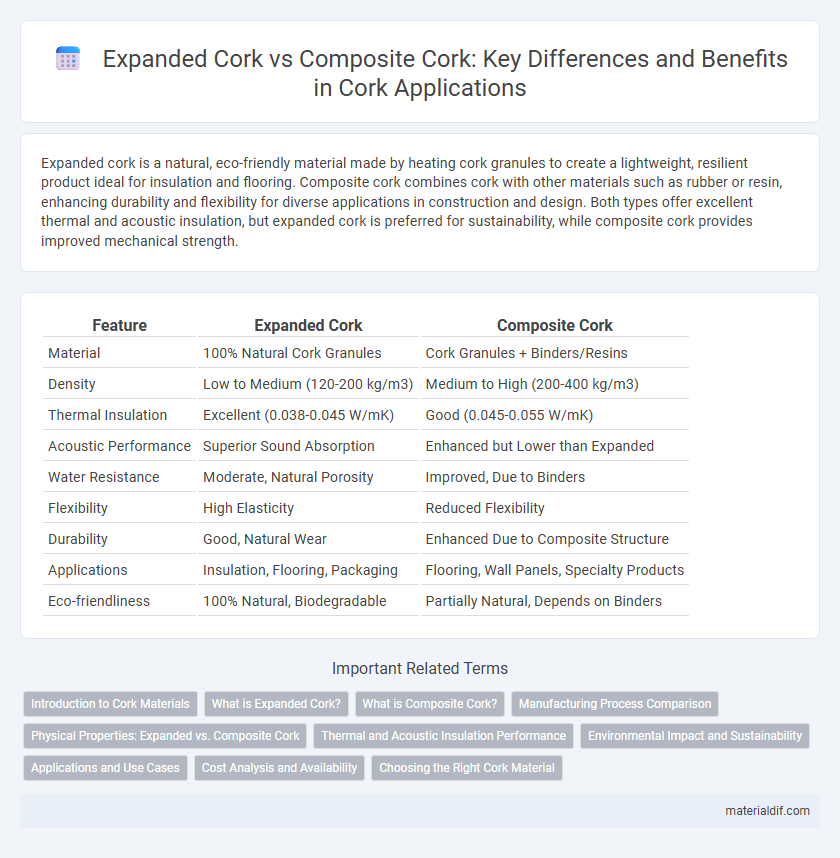

Expanded cork is a natural, eco-friendly material made by heating cork granules to create a lightweight, resilient product ideal for insulation and flooring. Composite cork combines cork with other materials such as rubber or resin, enhancing durability and flexibility for diverse applications in construction and design. Both types offer excellent thermal and acoustic insulation, but expanded cork is preferred for sustainability, while composite cork provides improved mechanical strength.

Table of Comparison

| Feature | Expanded Cork | Composite Cork |

|---|---|---|

| Material | 100% Natural Cork Granules | Cork Granules + Binders/Resins |

| Density | Low to Medium (120-200 kg/m3) | Medium to High (200-400 kg/m3) |

| Thermal Insulation | Excellent (0.038-0.045 W/mK) | Good (0.045-0.055 W/mK) |

| Acoustic Performance | Superior Sound Absorption | Enhanced but Lower than Expanded |

| Water Resistance | Moderate, Natural Porosity | Improved, Due to Binders |

| Flexibility | High Elasticity | Reduced Flexibility |

| Durability | Good, Natural Wear | Enhanced Due to Composite Structure |

| Applications | Insulation, Flooring, Packaging | Flooring, Wall Panels, Specialty Products |

| Eco-friendliness | 100% Natural, Biodegradable | Partially Natural, Depends on Binders |

Introduction to Cork Materials

Expanded cork is a natural, sustainable material obtained by heating cork granules, which causes them to expand and bind together without adhesives, resulting in a lightweight, resilient product ideal for insulation and acoustic panels. Composite cork combines cork with other materials like rubber or polymers, enhancing durability and flexibility for applications in flooring, gaskets, and sports equipment. Both materials leverage cork's inherent properties, such as thermal insulation, water resistance, and compressibility, but differ in structure and versatility based on processing methods.

What is Expanded Cork?

Expanded cork is a natural, lightweight material produced by heating cork granules until they expand and bind together without using adhesives, resulting in a resilient and sustainable product. It offers superior insulation properties, sound absorption, and durability compared to composite cork, which combines cork with synthetic binders or other materials. Expanded cork is widely used in construction, flooring, and sports equipment due to its eco-friendly characteristics and excellent performance.

What is Composite Cork?

Composite cork is a versatile material made by combining natural cork granules with binders such as polyurethane or resin, resulting in enhanced durability and flexibility compared to expanded cork. It offers improved resistance to moisture, wear, and impact, making it ideal for flooring, insulation, and soundproofing applications. Unlike expanded cork, which is processed into larger blocks or sheets, composite cork provides customizable properties tailored to specific industrial and architectural uses.

Manufacturing Process Comparison

Expanded cork involves heating raw cork granules until they expand and bind naturally, producing a lightweight, flexible material without added adhesives. Composite cork combines cork granules with synthetic binders, which are mixed and pressed under heat and pressure to form a denser, more rigid product. The manufacturing process of expanded cork emphasizes eco-friendly techniques and natural cohesion, while composite cork relies on chemical bonding to enhance mechanical strength.

Physical Properties: Expanded vs. Composite Cork

Expanded cork exhibits superior thermal insulation and resilience due to its natural cell structure, providing excellent compressive strength and durability. Composite cork combines cork granules with synthetic binders, resulting in enhanced flexibility and moisture resistance but typically lower insulation performance. The choice between expanded and composite cork depends on specific physical property requirements such as insulation efficiency, flexibility, and environmental exposure.

Thermal and Acoustic Insulation Performance

Expanded cork offers superior thermal insulation due to its natural cellular structure, which effectively reduces heat transfer and energy loss. Composite cork combines cork granules with synthetic binders, providing enhanced acoustic insulation by absorbing sound waves and minimizing noise pollution. Both materials excel in eco-friendly applications, but expanded cork is preferred for thermal efficiency, while composite cork is favored for soundproofing performance.

Environmental Impact and Sustainability

Expanded cork offers a highly sustainable option as it is produced by heating granulated cork without additional binders, preserving its natural properties and biodegradability. Composite cork, which combines cork granules with synthetic binders, may compromise environmental benefits due to the presence of non-biodegradable materials and potential chemical emissions. The use of expanded cork significantly reduces carbon footprint and promotes circular economy principles, making it a more environmentally friendly choice compared to composite cork alternatives.

Applications and Use Cases

Expanded cork offers superior insulation and soundproofing properties, making it ideal for construction, flooring, and thermal insulation in eco-friendly buildings. Composite cork combines cork granules with binders, enhancing durability and flexibility for use in footwear soles, sports equipment, and fashion accessories. Both materials excel in sustainable solutions, with expanded cork prioritizing natural resilience and composite cork allowing customization for diverse industrial applications.

Cost Analysis and Availability

Expanded cork offers a higher cost due to its more complex manufacturing process but provides superior insulation and durability, making it a premium choice for specialized applications. Composite cork, made by blending cork granules with binders or other materials, is generally more affordable and widely available, supporting large-scale construction projects with budget constraints. Availability of composite cork is more consistent worldwide, while expanded cork may face supply limitations depending on production capacity and regional demand.

Choosing the Right Cork Material

Expanded cork offers superior thermal insulation and water resistance, making it ideal for construction and insulation applications. Composite cork combines cork granules with binders, enhancing flexibility and durability for use in flooring and fashion accessories. Selecting the right cork material depends on evaluating performance requirements such as insulation, moisture resistance, and mechanical strength.

expanded cork vs composite cork Infographic

materialdif.com

materialdif.com