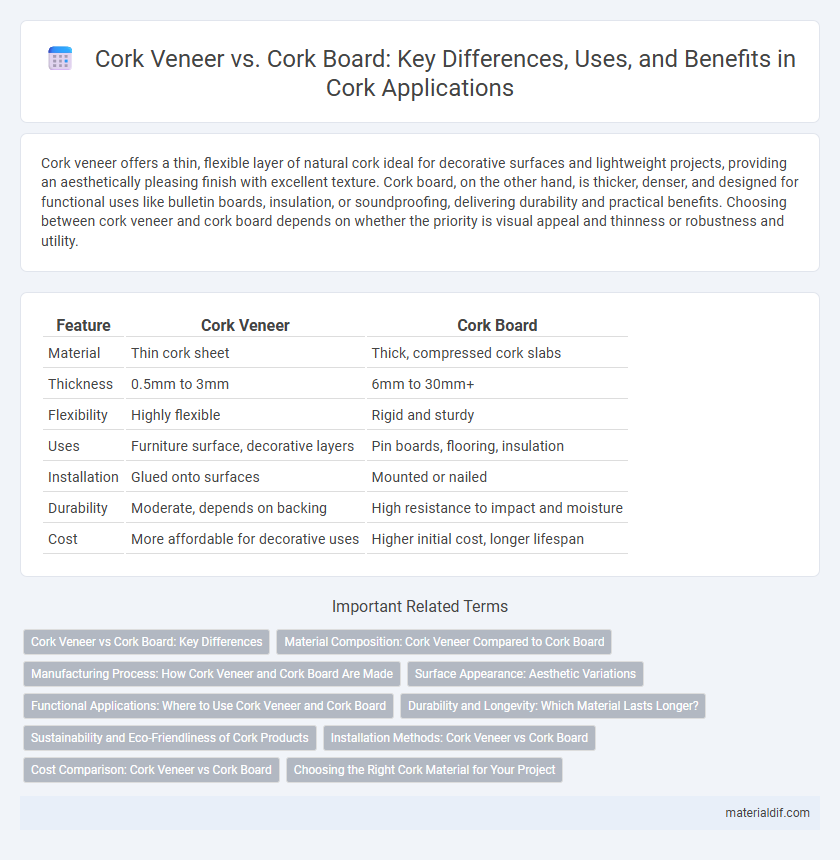

Cork veneer offers a thin, flexible layer of natural cork ideal for decorative surfaces and lightweight projects, providing an aesthetically pleasing finish with excellent texture. Cork board, on the other hand, is thicker, denser, and designed for functional uses like bulletin boards, insulation, or soundproofing, delivering durability and practical benefits. Choosing between cork veneer and cork board depends on whether the priority is visual appeal and thinness or robustness and utility.

Table of Comparison

| Feature | Cork Veneer | Cork Board |

|---|---|---|

| Material | Thin cork sheet | Thick, compressed cork slabs |

| Thickness | 0.5mm to 3mm | 6mm to 30mm+ |

| Flexibility | Highly flexible | Rigid and sturdy |

| Uses | Furniture surface, decorative layers | Pin boards, flooring, insulation |

| Installation | Glued onto surfaces | Mounted or nailed |

| Durability | Moderate, depends on backing | High resistance to impact and moisture |

| Cost | More affordable for decorative uses | Higher initial cost, longer lifespan |

Cork Veneer vs Cork Board: Key Differences

Cork veneer is a thin, flexible layer of natural cork typically used for decorative surfaces and lightweight applications, whereas corkboard is a thicker, rigid panel designed for pinning and bulletin purposes. Cork veneer offers smoother texture and greater aesthetic appeal, making it ideal for furniture and wall coverings, while corkboard prioritizes durability and practicality in office or classroom settings. The distinction in thickness and intended use defines cork veneer as a finishing material, contrasting with corkboard's functional role.

Material Composition: Cork Veneer Compared to Cork Board

Cork veneer consists of thin slices of cork harvested from the outer bark of cork oak trees, offering a flexible, lightweight material ideal for decorative surfaces and fine woodworking. In contrast, cork board is made from compressed granules of cork that are glued together, resulting in a denser, more rigid product commonly used for bulletin boards, insulation, and flooring underlayment. The sap-like substance called suberin in both materials provides natural moisture resistance and durability, but the structural differences in composition dictate their respective applications and performance characteristics.

Manufacturing Process: How Cork Veneer and Cork Board Are Made

Cork veneer is produced by slicing thin layers from the outer bark of cork oak trees, which are then dried and treated to maintain flexibility and uniform thickness, ideal for decorative applications. In contrast, cork board manufacturing involves grinding cork granules from lower-quality or leftover bark, which are then compressed and heat-pressed into dense, rigid sheets used mainly for insulation and bulletin boards. Both processes utilize sustainable harvesting methods from the Quercus suber tree, ensuring environmental responsibility while catering to different functional needs.

Surface Appearance: Aesthetic Variations

Cork veneer exhibits a smoother, more refined surface appearance with consistent grain patterns ideal for decorative applications, while cork board features a coarser, natural texture showcasing irregular granules suited for functional uses like bulletin boards. The aesthetic variations highlight cork veneer's uniformity and subtle elegance, contrasting with the rustic and tactile quality of cork board. These differences influence the choice depending on whether visual appeal or practical texture is prioritized in interior design or craft projects.

Functional Applications: Where to Use Cork Veneer and Cork Board

Cork veneer is ideal for decorative surfaces, furniture overlays, and lightweight paneling due to its thin, flexible structure that enhances aesthetic appeal without adding bulk. Cork board excels in insulation, soundproofing, and bulletin board applications, offering durability and thickness for functional performance in walls, floors, and office environments. Choosing between cork veneer and cork board depends on whether the project demands a sleek finish or robust protective properties.

Durability and Longevity: Which Material Lasts Longer?

Cork veneer offers a thin, flexible layer of natural cork that is less durable and more prone to wear over time compared to cork board, which consists of thicker, denser material providing enhanced resistance to impact and moisture. Cork boards typically last significantly longer in high-traffic or high-moisture environments due to their robust structure and superior longevity. For applications requiring extended durability, cork board is the preferred choice due to its ability to maintain integrity and appearance over prolonged use.

Sustainability and Eco-Friendliness of Cork Products

Cork veneer and cork board both offer sustainable and eco-friendly benefits derived from the renewable bark of cork oak trees, which regenerates without harming the tree. Cork veneer utilizes thin layers, minimizing raw material use and reducing waste, whereas cork board is thicker, providing durability with natural insulation and carbon sequestration properties. Both products support sustainable forestry practices and contribute to reducing environmental impact through biodegradability and low energy production processes.

Installation Methods: Cork Veneer vs Cork Board

Cork veneer requires precise adhesive application and careful layering onto smooth surfaces, making it ideal for walls and furniture with minimal thickness. Cork board installation involves mechanical fastening or adhesive gluing, suited for bulletin boards and insulation with thicker, rigid panels. Both methods demand surface preparation, but cork veneer emphasizes seamless bonding while cork board focuses on structural stability.

Cost Comparison: Cork Veneer vs Cork Board

Cork veneer typically costs more per square foot than cork board due to its thinner profile and higher processing requirements. Cork board offers a more budget-friendly option for larger surface coverage while providing effective insulation and cushioning properties. Choosing between cork veneer and cork board depends on project scale and cost constraints, with cork board favored for affordable, extensive applications.

Choosing the Right Cork Material for Your Project

Cork veneer offers a thin, flexible layer ideal for decorative applications and lightweight projects, while cork board provides a thicker, more durable option suited for insulation, soundproofing, and bulletin boards. When choosing the right cork material, consider the project's functional requirements such as flexibility, thickness, and durability to ensure optimal performance. Understanding the differences in texture, density, and application helps select the appropriate cork product for efficient and effective results.

Cork Veneer vs Cork Board Infographic

materialdif.com

materialdif.com