Expandable cork offers superior flexibility and resilience, making it ideal for applications requiring cushioning or insulation. Pressed cork, created through compression of cork granules, provides a denser, more rigid material suited for flooring and decorative panels. Both types are sustainable options, but expandable cork excels in adaptability while pressed cork delivers structural stability.

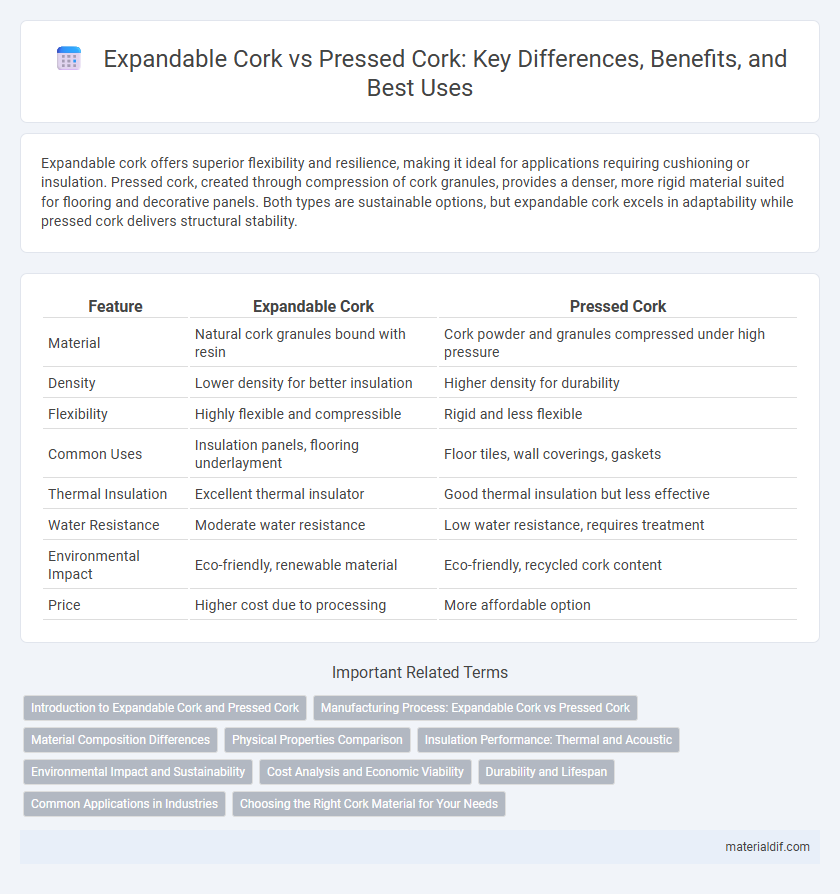

Table of Comparison

| Feature | Expandable Cork | Pressed Cork |

|---|---|---|

| Material | Natural cork granules bound with resin | Cork powder and granules compressed under high pressure |

| Density | Lower density for better insulation | Higher density for durability |

| Flexibility | Highly flexible and compressible | Rigid and less flexible |

| Common Uses | Insulation panels, flooring underlayment | Floor tiles, wall coverings, gaskets |

| Thermal Insulation | Excellent thermal insulator | Good thermal insulation but less effective |

| Water Resistance | Moderate water resistance | Low water resistance, requires treatment |

| Environmental Impact | Eco-friendly, renewable material | Eco-friendly, recycled cork content |

| Price | Higher cost due to processing | More affordable option |

Introduction to Expandable Cork and Pressed Cork

Expandable cork, derived from natural cork bark granules, undergoes a heating process causing the granules to expand and fuse into lightweight, flexible blocks ideal for insulation and packaging. Pressed cork results from finely ground cork particles compressed with adhesive binders, producing a denser, rigid material commonly used in flooring, gaskets, and bulletin boards. Both materials harness cork's natural properties but differ in texture, density, and typical applications.

Manufacturing Process: Expandable Cork vs Pressed Cork

Expandable cork is produced by heating cork granules, causing them to expand and bind naturally without synthetic adhesives, resulting in a more resilient and insulation-efficient material. Pressed cork involves compressing cork dust or chips with resins or glues under high pressure, forming rigid blocks or sheets with less elasticity. The manufacturing process of expandable cork emphasizes natural expansion and minimal processing, whereas pressed cork relies on additives and mechanical compression for shape and density control.

Material Composition Differences

Expandable cork consists of natural cork granules heated and expanded to create a lightweight, porous structure with high flexibility and thermal insulation properties. Pressed cork is made by compressing cork granules with binders under high pressure, resulting in a denser, less flexible material with uniform thickness and greater mechanical strength. The primary material composition difference lies in the absence of binders in expandable cork, preserving its natural cellular structure, while pressed cork incorporates binding agents that alter its texture and durability.

Physical Properties Comparison

Expandable cork exhibits a more porous, lightweight structure with superior elasticity and resilience, making it ideal for insulation and acoustic applications. Pressed cork, created by compressing granulated cork with binders, offers higher density and rigidity, resulting in greater durability and compressive strength. The differences in porosity and mechanical properties directly influence their suitability for various industrial and consumer uses.

Insulation Performance: Thermal and Acoustic

Expandable cork offers superior thermal insulation with a low thermal conductivity typically around 0.04 W/m*K, making it highly effective in maintaining indoor temperatures. Pressed cork, while denser and more rigid, generally exhibits slightly higher thermal conductivity, reducing its insulation efficiency compared to expandable cork. Acoustically, expandable cork's cellular structure provides excellent sound absorption and noise reduction, outperforming pressed cork in minimizing airborne and impact noise transmission.

Environmental Impact and Sustainability

Expandable cork is harvested sustainably from the bark of cork oak trees without harming the tree, promoting biodiversity and carbon sequestration in cork forests. Pressed cork, produced by agglomerating cork granules with adhesives, involves more energy-intensive processing and potential chemical use, resulting in a higher environmental footprint. The natural regeneration of cork oak ecosystems and the biodegradable nature of expandable cork make it a greener choice compared to the industrial manufacturing of pressed cork products.

Cost Analysis and Economic Viability

Expandable cork typically incurs higher production costs due to its complex harvesting and processing methods, yet it offers superior durability and insulating properties that enhance long-term economic viability. Pressed cork, derived from agglomerated cork granules, presents a cost-effective alternative with lower initial investment but may require more frequent replacement due to reduced resilience. Evaluating lifecycle expenses, expandable cork proves more economically advantageous for applications demanding longevity and performance, while pressed cork serves budget-conscious projects with less stringent durability requirements.

Durability and Lifespan

Expandable cork, harvested by boiling cork oak bark, offers superior durability and a longer lifespan compared to pressed cork, which is made by compressing cork granules with adhesive. Its cellular structure remains intact, providing enhanced resilience, water resistance, and resistance to wear and tear in flooring and insulation applications. Pressed cork, while economical, tends to degrade faster and is more susceptible to damage from moisture and repeated stress.

Common Applications in Industries

Expandable cork is widely utilized in insulation, sealing, and gaskets across automotive, construction, and aerospace industries due to its flexibility and excellent thermal properties. Pressed cork, characterized by its density and uniformity, finds common applications in flooring, bulletin boards, and fashion accessories, favored for durability and aesthetic appeal. Both forms serve specialized roles, with expandable cork excelling in flexible seals while pressed cork offers structural and decorative advantages.

Choosing the Right Cork Material for Your Needs

Expandable cork offers superior elasticity and water resistance, making it ideal for insulation and soundproofing applications. Pressed cork, composed of granulated cork bonded with resin, is denser and better suited for flooring and decorative purposes where durability is essential. Selecting the right cork material depends on factors like flexibility, compression resistance, and intended use environment to ensure optimal performance.

expandable cork vs pressed cork Infographic

materialdif.com

materialdif.com