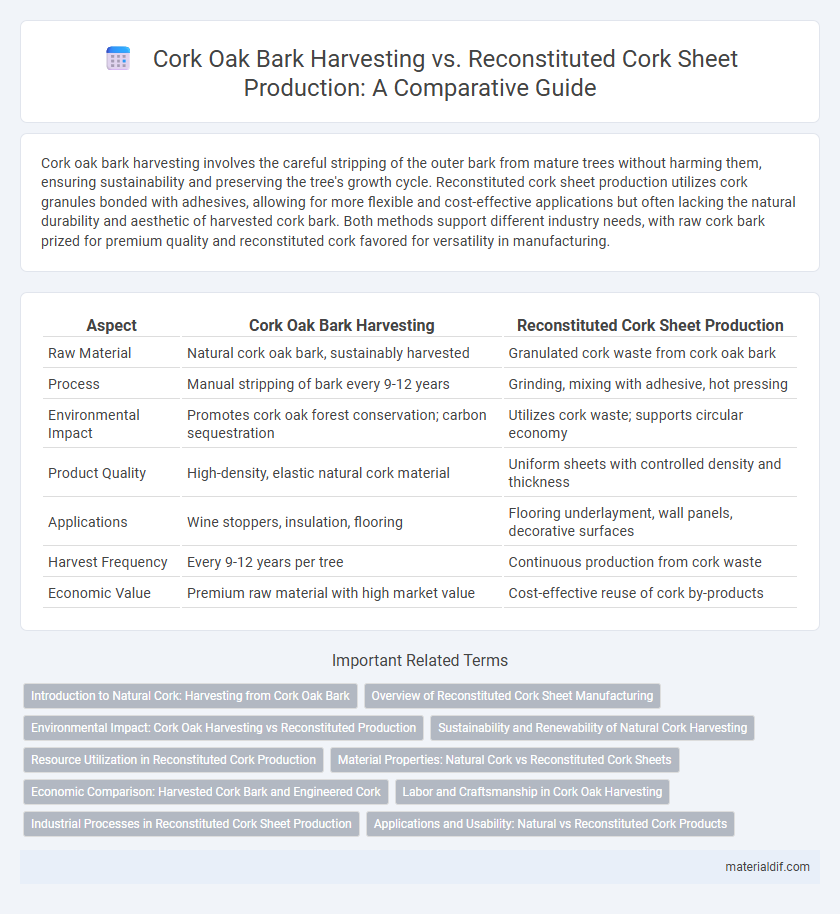

Cork oak bark harvesting involves the careful stripping of the outer bark from mature trees without harming them, ensuring sustainability and preserving the tree's growth cycle. Reconstituted cork sheet production utilizes cork granules bonded with adhesives, allowing for more flexible and cost-effective applications but often lacking the natural durability and aesthetic of harvested cork bark. Both methods support different industry needs, with raw cork bark prized for premium quality and reconstituted cork favored for versatility in manufacturing.

Table of Comparison

| Aspect | Cork Oak Bark Harvesting | Reconstituted Cork Sheet Production |

|---|---|---|

| Raw Material | Natural cork oak bark, sustainably harvested | Granulated cork waste from cork oak bark |

| Process | Manual stripping of bark every 9-12 years | Grinding, mixing with adhesive, hot pressing |

| Environmental Impact | Promotes cork oak forest conservation; carbon sequestration | Utilizes cork waste; supports circular economy |

| Product Quality | High-density, elastic natural cork material | Uniform sheets with controlled density and thickness |

| Applications | Wine stoppers, insulation, flooring | Flooring underlayment, wall panels, decorative surfaces |

| Harvest Frequency | Every 9-12 years per tree | Continuous production from cork waste |

| Economic Value | Premium raw material with high market value | Cost-effective reuse of cork by-products |

Introduction to Natural Cork: Harvesting from Cork Oak Bark

Natural cork is sustainably harvested from the bark of cork oak trees (Quercus suber) every 9 to 12 years without harming the tree, enabling continuous growth and regeneration. This traditional method preserves the unique cellular structure of cork, essential for its elasticity, impermeability, and thermal insulation properties. In contrast, reconstituted cork sheets are produced by agglomerating cork granules with adhesives, resulting in a less durable material that lacks the natural qualities of virgin bark cork.

Overview of Reconstituted Cork Sheet Manufacturing

Reconstituted cork sheet manufacturing involves agglomerating cork granules derived from cork oak bark residues through heat and pressure, creating a versatile and sustainable material. This process maximizes raw material usage by utilizing cork dust and small pieces typically discarded during traditional cork oak bark harvesting. The resulting cork sheets maintain durability and flexibility, making them ideal for diverse applications such as flooring, insulation, and gasket production.

Environmental Impact: Cork Oak Harvesting vs Reconstituted Production

Cork oak bark harvesting is a sustainable practice that supports biodiversity and carbon sequestration, as the trees are not cut down and can regenerate bark every 9-12 years, preserving mature forests and their ecosystems. In contrast, reconstituted cork sheet production involves processing cork waste and by-products, reducing material waste but requiring additional energy and chemical treatments that can increase the environmental footprint. While both methods contribute to cork utilization, harvesting cork oak bark has a lower overall environmental impact due to its renewable and low-impact nature.

Sustainability and Renewability of Natural Cork Harvesting

Natural cork oak bark harvesting is a sustainable process that allows trees to regenerate their bark every 9 to 12 years without harm, ensuring continuous carbon sequestration and promoting biodiversity in cork oak forests. In contrast, reconstituted cork sheets are made from cork granules bonded with synthetic resins, which involve energy-intensive manufacturing and limited biodegradability, reducing their overall environmental benefits. The renewability of natural cork harvesting supports circular economy principles by preserving forest ecosystems and minimizing waste, making it the eco-friendlier choice for cork products.

Resource Utilization in Reconstituted Cork Production

Reconstituted cork production maximizes resource utilization by using cork dust and waste from traditional cork oak bark harvesting, minimizing material loss. This process allows for the transformation of otherwise discarded cork particles into durable sheets, promoting sustainable industry practices. Efficient resource recovery reduces environmental impact compared to solely relying on natural cork planks from harvested bark.

Material Properties: Natural Cork vs Reconstituted Cork Sheets

Natural cork harvested from cork oak bark features a cellular, honeycomb structure that provides exceptional elasticity, compressibility, and resistance to moisture and fire. Reconstituted cork sheets, made by agglomerating cork granules with binders, offer more uniform density and enhanced machinability but may exhibit reduced resilience and breathability compared to natural cork. The intrinsic properties of natural cork, such as superior insulation and durability, often make it preferred for high-performance applications despite the cost-effectiveness of reconstituted cork sheets.

Economic Comparison: Harvested Cork Bark and Engineered Cork

Harvested cork bark from cork oak trees generates significant economic value through sustainable extraction methods that preserve the tree's lifespan for up to 200 years, supporting rural economies in Mediterranean regions. Engineered cork sheets, produced by agglomerating cork granules with binders, offer cost-effective material alternatives but often depend on the supply and quality of raw cork bark, influencing market prices and product applications. The cork bark industry drives higher profit margins due to natural product demand, while engineered cork provides scalability and consistency for industrial uses with lower production costs.

Labor and Craftsmanship in Cork Oak Harvesting

Cork oak bark harvesting demands skilled laborers who carefully strip the bark by hand to preserve the tree's health, showcasing traditional craftsmanship passed down through generations. This labor-intensive process requires precision and experience to ensure sustainable yields without damaging the cork oak trees. In contrast, reconstituted cork sheet production relies more on industrial processes with less hands-on craftsmanship, focusing on recycling cork granules into usable sheets.

Industrial Processes in Reconstituted Cork Sheet Production

Reconstituted cork sheet production involves grinding cork oak bark into granules, which are then mixed with adhesives and subjected to high-pressure compression and heat curing to form uniform sheets. This industrial process contrasts with traditional cork oak bark harvesting, where the bark is manually stripped from live trees every 9 to 12 years without harming them, preserving natural cork quality. Advanced reconstituted cork manufacturing ensures efficient use of cork waste, enabling large-scale production for flooring, insulation, and other applications.

Applications and Usability: Natural vs Reconstituted Cork Products

Natural cork from cork oak bark harvesting is highly favored for wine stoppers, flooring, and insulation due to its superior elasticity, breathability, and eco-friendly qualities. Reconstituted cork sheets, made from ground cork granules bonded with adhesives, offer consistent density and versatility suitable for fashion accessories, bulletin boards, and craft materials. While natural cork excels in high-performance applications requiring durability and moisture resistance, reconstituted cork provides cost-effective solutions with customizable thickness and texture for diverse industrial uses.

cork oak bark harvesting vs reconstituted cork sheet production Infographic

materialdif.com

materialdif.com