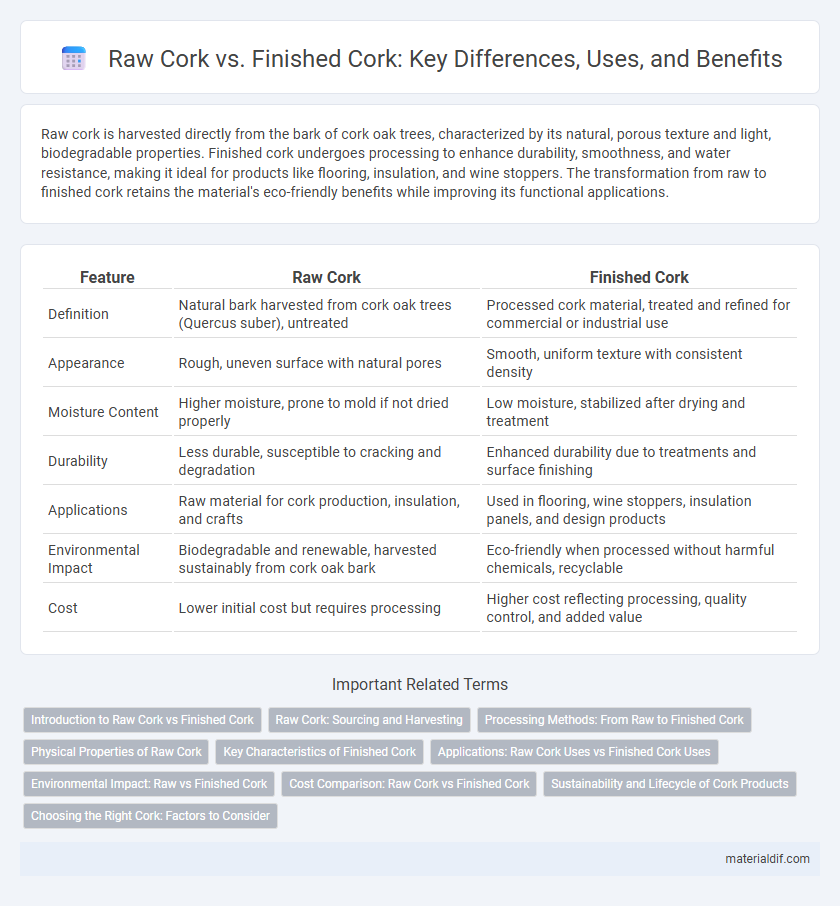

Raw cork is harvested directly from the bark of cork oak trees, characterized by its natural, porous texture and light, biodegradable properties. Finished cork undergoes processing to enhance durability, smoothness, and water resistance, making it ideal for products like flooring, insulation, and wine stoppers. The transformation from raw to finished cork retains the material's eco-friendly benefits while improving its functional applications.

Table of Comparison

| Feature | Raw Cork | Finished Cork |

|---|---|---|

| Definition | Natural bark harvested from cork oak trees (Quercus suber), untreated | Processed cork material, treated and refined for commercial or industrial use |

| Appearance | Rough, uneven surface with natural pores | Smooth, uniform texture with consistent density |

| Moisture Content | Higher moisture, prone to mold if not dried properly | Low moisture, stabilized after drying and treatment |

| Durability | Less durable, susceptible to cracking and degradation | Enhanced durability due to treatments and surface finishing |

| Applications | Raw material for cork production, insulation, and crafts | Used in flooring, wine stoppers, insulation panels, and design products |

| Environmental Impact | Biodegradable and renewable, harvested sustainably from cork oak bark | Eco-friendly when processed without harmful chemicals, recyclable |

| Cost | Lower initial cost but requires processing | Higher cost reflecting processing, quality control, and added value |

Introduction to Raw Cork vs Finished Cork

Raw cork, harvested from the outer bark of Quercus suber trees, maintains its natural texture, moisture, and cellular structure, making it ideal for further processing. Finished cork undergoes treatments such as drying, boiling, and cutting, resulting in a more stable, durable, and versatile material used in products ranging from wine stoppers to flooring. Understanding the differences in physical properties and applications between raw and finished cork is essential for optimizing quality and performance in cork-based industries.

Raw Cork: Sourcing and Harvesting

Raw cork is sourced primarily from the bark of the Quercus suber tree, native to the Mediterranean region, with Portugal being the largest producer, contributing over 50% of global cork supply. Harvesting involves carefully stripping the outer bark every 9-12 years without harming the tree, allowing regeneration and sustainable production. The quality of raw cork depends on factors such as tree age, soil conditions, and climate, directly influencing its density and elasticity for various industrial applications.

Processing Methods: From Raw to Finished Cork

Raw cork is harvested from the bark of cork oak trees and undergoes a careful drying process to reduce moisture content and enhance durability. The cork is then boiled to remove impurities and improve flexibility before being cut and shaped into finished products such as wine stoppers, flooring, or insulation materials. Advanced finishing techniques include sanding, coating, and branding to ensure high-quality aesthetics and performance in various applications.

Physical Properties of Raw Cork

Raw cork exhibits a unique cellular structure characterized by lightweight, compressible, and elastic properties due to its honeycomb-like, air-filled cells. This natural material offers excellent thermal insulation, impermeability to liquids and gases, and high resistance to wear and decay. The physical properties of raw cork, including low density and remarkable resilience, make it an essential raw material for producing finished cork products such as flooring, insulation panels, and gaskets.

Key Characteristics of Finished Cork

Finished cork features enhanced durability, water resistance, and a smooth, uniform texture compared to raw cork, which is porous and less stable. The processing of raw cork involves cleaning, boiling, and pressing, resulting in improved dimensional stability and resistance to wear and tear. These key characteristics make finished cork ideal for applications in flooring, insulation, and fashion accessories.

Applications: Raw Cork Uses vs Finished Cork Uses

Raw cork, harvested directly from cork oak trees, is primarily used in insulation, soundproofing, and industrial applications due to its natural elasticity and thermal properties. Finished cork undergoes processing to create products like flooring, wine stoppers, bulletin boards, and fashion accessories, benefiting from its durability, smooth texture, and aesthetic appeal. The choice between raw cork and finished cork depends on the specific application requirements, such as structural support versus refined design elements.

Environmental Impact: Raw vs Finished Cork

Raw cork harvesting supports sustainable forest management by allowing trees to regenerate their bark without cutting them down, promoting carbon sequestration and biodiversity. Finished cork products, while energy-intensive during manufacturing, offer long-lasting, biodegradable uses that reduce landfill waste compared to synthetic alternatives. The environmental footprint of raw cork is lower initially, but the durability and recyclability of finished cork maximize its eco-friendly benefits over time.

Cost Comparison: Raw Cork vs Finished Cork

Raw cork, sourced directly from cork oak bark, presents a significantly lower cost due to minimal processing requirements, making it an economical choice for bulk industrial applications. Finished cork undergoes extensive refinement, including cutting, shaping, and quality control, which elevates its price but ensures superior durability and aesthetic appeal for consumer products such as flooring, wine stoppers, and insulation panels. The cost disparity between raw and finished cork reflects the added value of production labor, technological input, and market-ready standards essential for end-use functionality.

Sustainability and Lifecycle of Cork Products

Raw cork is harvested sustainably from the bark of cork oak trees, which regenerate every 9 to 12 years without harming the tree, ensuring a renewable resource with a minimal ecological footprint. Finished cork products, such as flooring or wine stoppers, benefit from cork's durability, biodegradability, and ability to be recycled or upcycled, extending their lifecycle and reducing environmental impact. The sustainable harvesting process coupled with the long lifespan of cork products supports carbon sequestration and promotes circular economy principles in the cork industry.

Choosing the Right Cork: Factors to Consider

Raw cork features a rough texture and higher porosity, making it ideal for tasks requiring natural elasticity and breathability, while finished cork offers smooth surfaces and enhanced durability suitable for interior design and flooring. When choosing the right cork, consider factors such as moisture resistance, surface finish, density, and intended application to ensure optimal performance. Evaluating environmental impact and sourcing sustainability also plays a crucial role in selecting premium cork materials.

raw cork vs finished cork Infographic

materialdif.com

materialdif.com