Solid cork sheets offer superior durability and consistency, making them ideal for detailed projects requiring precise thickness and shape. Cork rolls provide flexibility and ease of installation, especially suitable for larger surfaces or applications needing continuous, seamless coverage. Choosing between solid cork sheets and rolls depends on specific project requirements such as surface area, customization needs, and installation preferences.

Table of Comparison

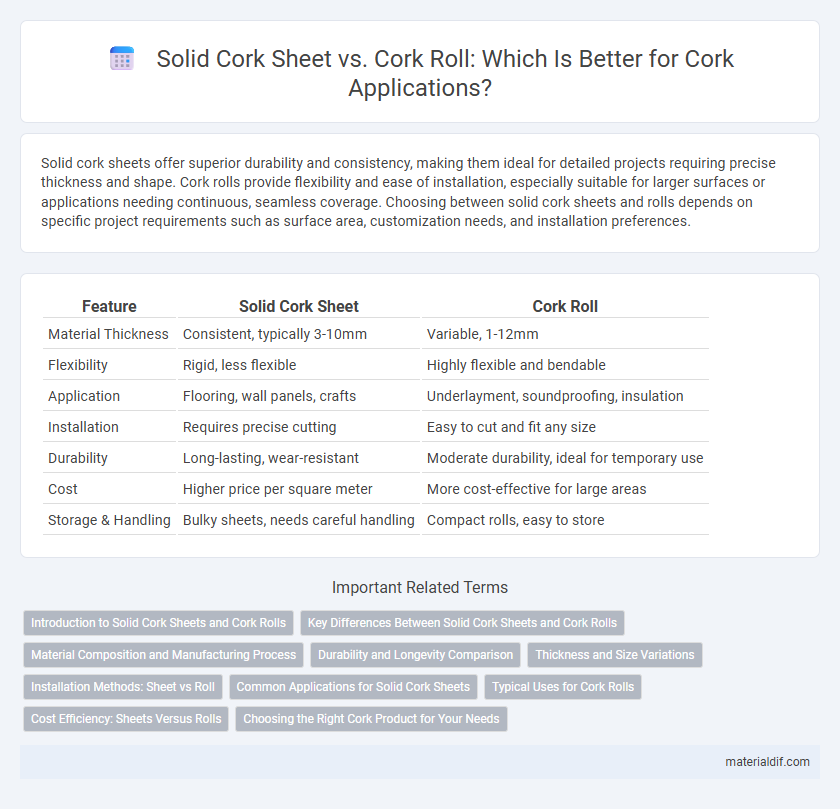

| Feature | Solid Cork Sheet | Cork Roll |

|---|---|---|

| Material Thickness | Consistent, typically 3-10mm | Variable, 1-12mm |

| Flexibility | Rigid, less flexible | Highly flexible and bendable |

| Application | Flooring, wall panels, crafts | Underlayment, soundproofing, insulation |

| Installation | Requires precise cutting | Easy to cut and fit any size |

| Durability | Long-lasting, wear-resistant | Moderate durability, ideal for temporary use |

| Cost | Higher price per square meter | More cost-effective for large areas |

| Storage & Handling | Bulky sheets, needs careful handling | Compact rolls, easy to store |

Introduction to Solid Cork Sheets and Cork Rolls

Solid cork sheets offer a dense, uniform surface ideal for flooring, wall panels, and insulation due to their durability and consistent thickness. Cork rolls provide flexibility and continuous lengths, making them suitable for wide-area applications and easy customization in decorative and acoustic projects. Both solid cork sheets and rolls leverage natural cork's thermal insulation, sound absorption, and moisture resistance properties for sustainable building solutions.

Key Differences Between Solid Cork Sheets and Cork Rolls

Solid cork sheets offer a consistent thickness and rigidity, making them ideal for precise applications such as flooring or paneling in Cork-based constructions. Cork rolls provide greater flexibility and ease of installation over large areas, commonly used for insulation or underlayment where adaptability to uneven surfaces is required. The choice between solid cork sheets and cork rolls in Cork projects depends on the balance between structural firmness and installation versatility.

Material Composition and Manufacturing Process

Solid cork sheets are produced from natural cork bark harvested primarily from Quercus suber trees, ensuring a dense, uniform structure ideal for durability and insulation. The manufacturing process involves carefully cutting and drying the cork bark into flat sheets, preserving the material's natural cellular composition to enhance resilience and moisture resistance. Cork rolls, by contrast, are created by granulating granules of cork and bonding them with adhesives or binders, allowing flexibility and customizable thickness but introducing synthetic components that may affect breathability and eco-friendliness.

Durability and Longevity Comparison

Solid cork sheets offer superior durability compared to cork rolls due to their uniform thickness and dense composition, which resists wear and compression over extended periods. Cork rolls, while flexible and suitable for large surface applications, tend to have variable thickness and may be more prone to tear or deformation under heavy use. The longevity of solid cork sheets generally surpasses cork rolls, making them a preferred choice for high-traffic areas and long-term installations.

Thickness and Size Variations

Solid cork sheets offer precise thickness options typically ranging from 1mm to 10mm, providing consistent uniformity ideal for detailed craft or architectural projects. Cork rolls, available in larger continuous lengths and widths up to 1 meter, allow greater flexibility for covering expansive surfaces but often come in standard thicknesses between 2mm and 6mm. Choice between solid sheets and rolls depends on the scale and precision required, with sheets favoring exact measurements and rolls maximizing coverage with moderate thickness variations.

Installation Methods: Sheet vs Roll

Solid cork sheets offer precise installation with clean edges, making them ideal for projects requiring uniformity and minimal seams. Cork rolls provide greater flexibility for covering large or irregular surfaces quickly, as they can be cut to size on-site and adapted to various shapes. Installation of sheets typically involves adhesive bonding and careful alignment, while rolls often require adhesive application and smoothing tools to avoid bubbles and wrinkles.

Common Applications for Solid Cork Sheets

Solid cork sheets are widely used in flooring, wall paneling, and soundproofing due to their durability and ease of installation. These sheets provide superior insulation and are ideal for craft projects, coasters, and bulletin boards because they can be cut to precise shapes without fraying. Compared to cork rolls, solid sheets offer more stability and uniform thickness, making them suitable for structural and decorative applications in both residential and commercial spaces.

Typical Uses for Cork Rolls

Cork rolls are typically used for insulation, underlayment, and vibration damping in construction and flooring applications due to their flexibility and ease of installation. They serve well in soundproofing walls and ceilings, as well as providing thermal insulation in HVAC systems. Compared to solid cork sheets, cork rolls offer greater adaptability for covering large or irregular surfaces efficiently.

Cost Efficiency: Sheets Versus Rolls

Solid cork sheets offer higher cost efficiency for small-scale or precision projects due to minimal waste and ease of handling, whereas cork rolls provide a more economical option for large-scale applications by reducing purchase frequency and enabling continuous coverage. Rolls typically have a lower price per square foot, benefiting bulk buyers needing extensive surface area coverage, while sheets minimize installation time and material loss in limited-use cases. Choosing between sheets and rolls depends on project size, budget constraints, and waste management priorities.

Choosing the Right Cork Product for Your Needs

Solid cork sheets offer greater durability and uniform thickness, making them ideal for precise applications like flooring and crafts, whereas cork rolls provide flexibility and continuous coverage, perfect for insulation and larger surface areas. Selecting the right cork product depends on project requirements such as size, thickness, and intended use, with sheets excelling in structural stability and rolls offering ease of installation. Cork's natural properties of thermal insulation, sound absorption, and eco-friendliness remain advantageous regardless of the chosen format.

solid cork sheet vs cork roll Infographic

materialdif.com

materialdif.com