Cork granules offer versatility for applications such as insulation and cushioning due to their loose, moldable form, while cork sheets provide durability and uniform thickness ideal for flooring, wall coverings, and bulletin boards. Granules allow for customization in packing and filling projects, whereas sheets deliver consistent density and smooth surfaces for structural uses. Choosing between cork granules and cork sheets depends on the specific requirements for flexibility, appearance, and application.

Table of Comparison

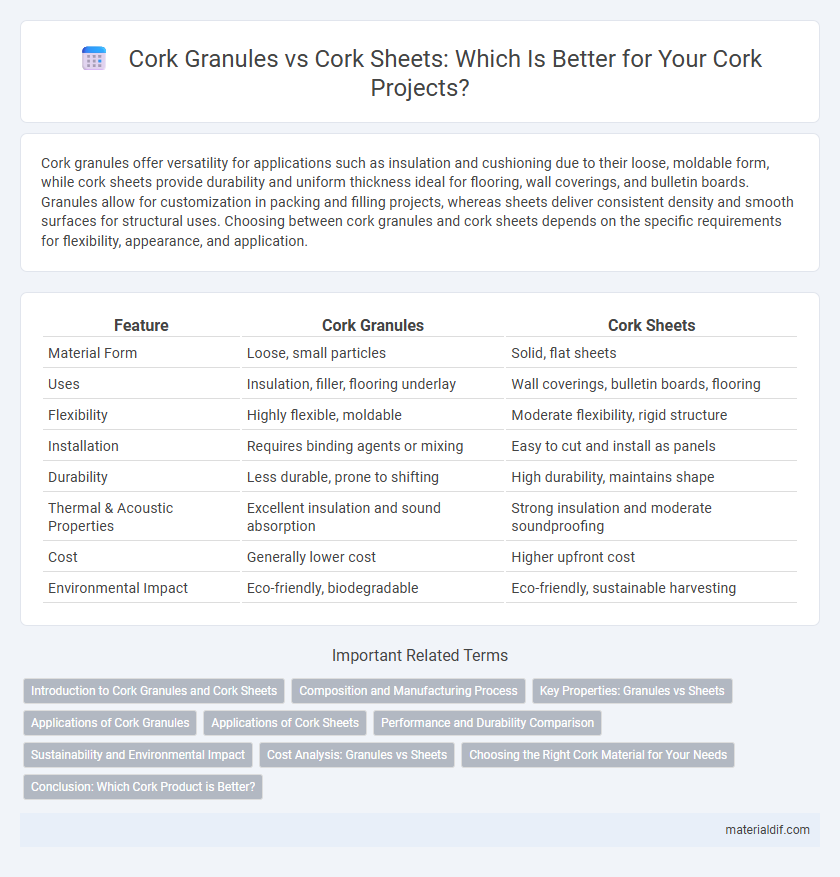

| Feature | Cork Granules | Cork Sheets |

|---|---|---|

| Material Form | Loose, small particles | Solid, flat sheets |

| Uses | Insulation, filler, flooring underlay | Wall coverings, bulletin boards, flooring |

| Flexibility | Highly flexible, moldable | Moderate flexibility, rigid structure |

| Installation | Requires binding agents or mixing | Easy to cut and install as panels |

| Durability | Less durable, prone to shifting | High durability, maintains shape |

| Thermal & Acoustic Properties | Excellent insulation and sound absorption | Strong insulation and moderate soundproofing |

| Cost | Generally lower cost | Higher upfront cost |

| Environmental Impact | Eco-friendly, biodegradable | Eco-friendly, sustainable harvesting |

Introduction to Cork Granules and Cork Sheets

Cork granules consist of small, irregularly shaped particles derived from crushed natural cork bark, widely used in insulation, gardening, and packaging due to their lightweight and compressible properties. Cork sheets are solid, flat pieces made by compressing and bonding cork granules or slicing cork bark, offering durability and smooth surfaces ideal for flooring, wall panels, and crafts. In Cork, granules offer versatility in filling and cushioning applications, while sheets provide structural integrity and aesthetic appeal for architectural and design projects.

Composition and Manufacturing Process

Cork granules are produced by grinding natural cork bark into small, irregular particles, typically used for thermal and acoustic insulation due to their porous structure. Cork sheets are made by compressing and bonding cork granules or thin cork layers under heat and pressure, resulting in a uniform and dense material ideal for flooring and wall coverings. The manufacturing process of sheets involves additional steps such as selecting granule size, binder incorporation, and curing, which differ significantly from the simpler granule production.

Key Properties: Granules vs Sheets

Cork granules offer superior thermal insulation and flexibility, making them ideal for irregular surfaces and fill applications, while cork sheets provide uniform thickness, durability, and easier handling for flooring, wall panels, and gaskets. Granules excel in sound absorption and shock resistance due to their loose, compressible nature, whereas sheets deliver consistent density and load-bearing capacity. The choice between cork granules and sheets depends on the specific application requirements, balancing insulation performance with structural stability.

Applications of Cork Granules

Cork granules are widely utilized in applications such as insulation for walls and floors, providing excellent thermal and acoustic properties due to their natural cellular structure. They are also popular in construction as lightweight fillers and in the manufacture of composite materials for enhanced durability and flexibility. Cork granules' versatility extends to horticulture, where they improve soil aeration and moisture retention in potting mixes.

Applications of Cork Sheets

Cork sheets are widely used in flooring, wall coverings, and insulation due to their durability, flexibility, and thermal properties, providing effective soundproofing and moisture resistance. Unlike cork granules, which are ideal for composite materials and lightweight applications, cork sheets offer a continuous, uniform surface preferred in crafts, automotive interiors, and bulletin boards. Their versatility and ease of cutting make cork sheets a popular choice for both industrial and decorative purposes in sustainable building projects.

Performance and Durability Comparison

Cork granules offer superior flexibility and are ideal for filling irregular spaces, providing enhanced shock absorption and thermal insulation, whereas cork sheets deliver consistent density and uniform thickness suited for structural applications. In terms of durability, cork sheets resist wear and compression better over time, making them preferable for flooring and wall panels, while granules may degrade faster under heavy pressure but excel in lightweight cushioning. Performance differences stem from their form factor: sheets maintain structural integrity longer, while granules adapt to varied shapes and provide excellent impact resistance in dynamic environments.

Sustainability and Environmental Impact

Cork granules, sourced from recycled cork waste, offer a highly sustainable option by reducing landfill use and promoting circular economy practices, whereas cork sheets, harvested from cork oak bark without tree felling, emphasize durability and renewable resource management. Cork granules provide enhanced insulation with minimal environmental disruption due to their repurposed origin, while cork sheets ensure long-term carbon sequestration through their natural, biodegradable properties. Both materials contribute significantly to eco-friendly building solutions, supporting biodiversity and reducing carbon footprints in sustainable construction projects.

Cost Analysis: Granules vs Sheets

Cork granules generally offer a more cost-effective solution compared to cork sheets due to lower production and shipping expenses linked to their loose form. Cork sheets tend to incur higher costs because of the processing required to produce uniform, solid panels and the waste generated during manufacturing. For projects prioritizing budget flexibility and material adaptability, cork granules provide a financially efficient alternative to the more rigid and pricier cork sheets.

Choosing the Right Cork Material for Your Needs

Cork granules offer superior flexibility and are ideal for filling irregular spaces or enhancing insulation in complex shapes, making them perfect for specialized applications. Cork sheets provide a uniform, durable surface that excels in flooring, underlayment, and wall paneling where consistent thickness and stability are essential. Selecting the right cork material depends on your project's requirements for adaptability, cushioning, and application area precision.

Conclusion: Which Cork Product is Better?

Cork granules provide versatile applications in insulation, soundproofing, and lightweight fillers, offering greater adaptability for custom projects. Cork sheets deliver superior structural integrity and a seamless finish, making them ideal for flooring, wall coverings, and furniture surfaces. The better cork product depends on specific needs: granules excel in flexibility and ease of installation, while sheets offer durability and consistent performance.

Cork Granules vs Cork Sheets Infographic

materialdif.com

materialdif.com