Cork insulation offers superior thermal performance and natural resistance to moisture and mold compared to fiberglass insulation, making it an ideal choice for damp environments in Cork's climate. Cork is a sustainable, eco-friendly material that provides excellent soundproofing and durability, whereas fiberglass is more affordable but less effective at blocking moisture and may cause respiratory irritation during installation. Choosing cork insulation enhances energy efficiency and indoor air quality in Cork homes, providing long-term benefits over traditional fiberglass options.

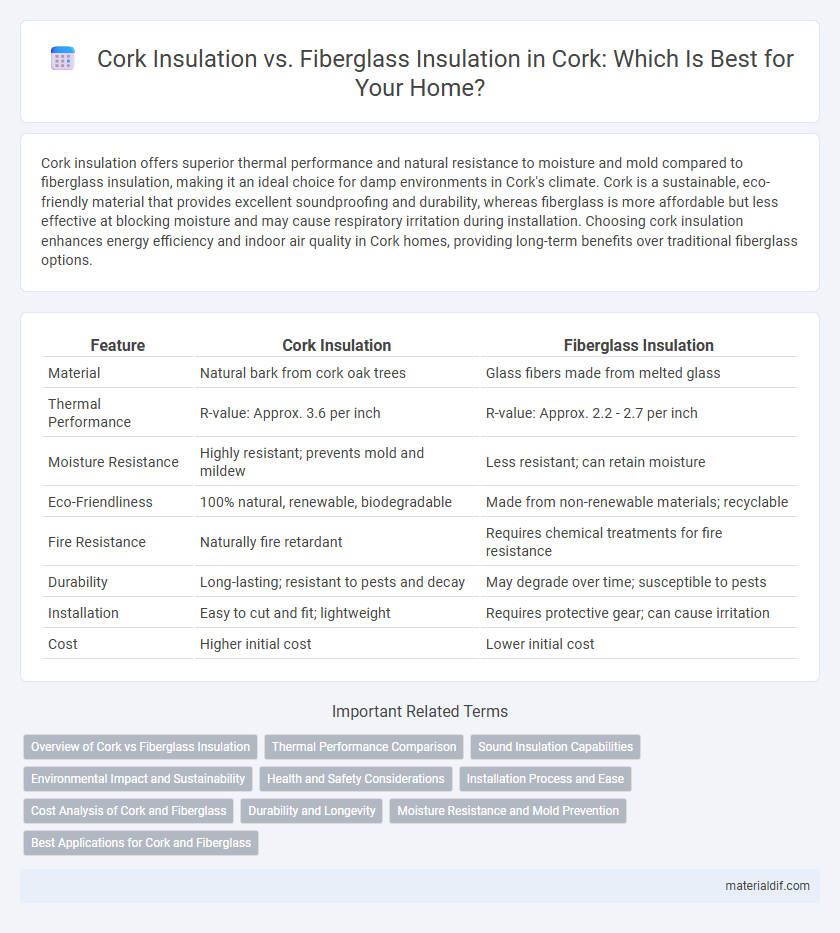

Table of Comparison

| Feature | Cork Insulation | Fiberglass Insulation |

|---|---|---|

| Material | Natural bark from cork oak trees | Glass fibers made from melted glass |

| Thermal Performance | R-value: Approx. 3.6 per inch | R-value: Approx. 2.2 - 2.7 per inch |

| Moisture Resistance | Highly resistant; prevents mold and mildew | Less resistant; can retain moisture |

| Eco-Friendliness | 100% natural, renewable, biodegradable | Made from non-renewable materials; recyclable |

| Fire Resistance | Naturally fire retardant | Requires chemical treatments for fire resistance |

| Durability | Long-lasting; resistant to pests and decay | May degrade over time; susceptible to pests |

| Installation | Easy to cut and fit; lightweight | Requires protective gear; can cause irritation |

| Cost | Higher initial cost | Lower initial cost |

Overview of Cork vs Fiberglass Insulation

Cork insulation offers superior thermal resistance and natural moisture control compared to fiberglass insulation, making it ideal for energy-efficient buildings. Fiberglass insulation, composed of fine glass fibers, provides effective soundproofing and is widely used due to its affordability and ease of installation. Both materials differ in durability and environmental impact, with cork favored for sustainability and fiberglass for cost-efficiency.

Thermal Performance Comparison

Cork insulation offers superior thermal performance compared to fiberglass insulation due to its natural cellular structure that provides excellent heat retention and breathability. Cork's R-value ranges from 3.6 to 4.2 per inch, making it more effective at reducing heat transfer than fiberglass, which typically has an R-value between 2.2 and 3.8 per inch. The combination of cork's low thermal conductivity and moisture-resistant properties enhances energy efficiency and maintains indoor comfort in various climates.

Sound Insulation Capabilities

Cork insulation offers superior sound absorption due to its natural cellular structure, effectively reducing noise transmission in residential and commercial spaces. Fiberglass insulation provides decent soundproofing but often falls short compared to cork, especially in blocking low-frequency sounds. The dense, flexible nature of cork makes it an ideal choice for enhancing acoustic comfort in buildings located in noisy environments.

Environmental Impact and Sustainability

Cork insulation offers superior environmental benefits compared to fiberglass insulation due to its renewable and biodegradable nature, being harvested from the bark of cork oak trees without harming the tree itself. Its low embodied energy and carbon footprint contribute to sustainability, while fiberglass insulation relies heavily on non-renewable resources and energy-intensive manufacturing processes. Using cork insulation enhances energy efficiency in buildings and supports sustainable forestry practices, making it a more eco-friendly choice for green construction.

Health and Safety Considerations

Cork insulation offers natural hypoallergenic properties and resists mold, making it a safer choice for indoor air quality compared to fiberglass insulation, which can release irritating glass fibers and dust during installation and over time. Cork is fire-resistant without toxic fumes, while fiberglass poses respiratory risks and requires protective gear during handling. Choosing cork insulation reduces long-term health hazards and minimizes environmental pollutants in residential and commercial buildings.

Installation Process and Ease

Cork insulation offers a straightforward installation process due to its lightweight, flexible sheets that easily fit into irregular spaces without requiring specialized tools, making it user-friendly for DIY projects. In contrast, fiberglass insulation involves handling itchy fibers, protective gear, and precise cutting to fit joists or studs, often necessitating professional installation for safety and effectiveness. Cork's natural adhesive properties and minimal dust production enhance ease of use, while fiberglass requires careful containment to prevent airborne particles during installation.

Cost Analysis of Cork and Fiberglass

Cork insulation typically costs between $3 and $7 per square foot, making it more expensive than fiberglass insulation, which ranges from $0.50 to $2 per square foot. The higher initial price of cork insulation reflects its eco-friendly properties, superior thermal performance, and durability, leading to long-term energy savings. Fiberglass insulation is budget-friendly for upfront installation but may incur higher maintenance and replacement costs over time compared to cork.

Durability and Longevity

Cork insulation offers superior durability and longevity compared to fiberglass insulation, as it naturally resists moisture, mold, and pests, extending its lifespan beyond 30 years under optimal conditions. Fiberglass insulation tends to degrade faster due to moisture absorption and compaction, often requiring replacement within 15 to 20 years. The insulation stability of cork supports consistent thermal performance over time, making it a more resilient choice for sustainable building applications in Cork's damp climate.

Moisture Resistance and Mold Prevention

Cork insulation offers superior moisture resistance compared to fiberglass insulation, effectively preventing water absorption and reducing the risk of mold growth in damp environments. Its natural cellular structure creates a breathable barrier that inhibits mold spores, making it ideal for areas prone to humidity and condensation. In contrast, fiberglass insulation can retain moisture if not properly installed, potentially fostering mold development and compromising indoor air quality.

Best Applications for Cork and Fiberglass

Cork insulation excels in applications requiring natural, sustainable materials with superior thermal and acoustic properties, making it ideal for eco-friendly homes, walls, floors, and ceilings with moisture resistance needs. Fiberglass insulation is best suited for standard residential and commercial buildings where cost-effectiveness and easy installation are priorities, particularly in attics, walls, and HVAC systems. Cork's durability and mold resistance outperform fiberglass in high-humidity environments, while fiberglass offers higher R-values per inch, optimizing thermal performance in tight spaces.

Cork Insulation vs Fiberglass Insulation Infographic

materialdif.com

materialdif.com