Cork rubber offers natural cushioning and superior shock absorption, making it environmentally friendly and durable for various applications. Neoprene provides excellent water resistance and flexibility, ideal for waterproof seals and wetsuits. Choosing between cork rubber and neoprene depends on the need for eco-conscious materials versus synthetic durability and elasticity.

Table of Comparison

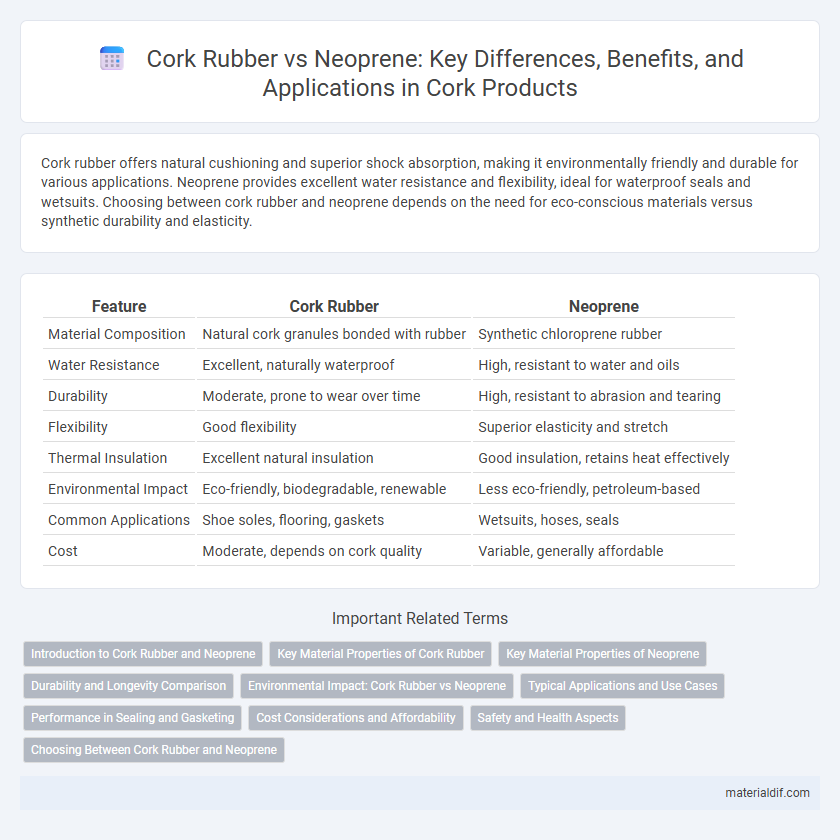

| Feature | Cork Rubber | Neoprene |

|---|---|---|

| Material Composition | Natural cork granules bonded with rubber | Synthetic chloroprene rubber |

| Water Resistance | Excellent, naturally waterproof | High, resistant to water and oils |

| Durability | Moderate, prone to wear over time | High, resistant to abrasion and tearing |

| Flexibility | Good flexibility | Superior elasticity and stretch |

| Thermal Insulation | Excellent natural insulation | Good insulation, retains heat effectively |

| Environmental Impact | Eco-friendly, biodegradable, renewable | Less eco-friendly, petroleum-based |

| Common Applications | Shoe soles, flooring, gaskets | Wetsuits, hoses, seals |

| Cost | Moderate, depends on cork quality | Variable, generally affordable |

Introduction to Cork Rubber and Neoprene

Cork rubber combines natural cork granules with synthetic rubber to create a lightweight, eco-friendly material known for excellent thermal insulation, sound absorption, and resistance to oil and chemicals. Neoprene, a synthetic rubber produced through polymerization of chloroprene, offers superior flexibility, weather resistance, and durability, making it ideal for wetsuits, gaskets, and seals. Both materials serve diverse industrial applications, with cork rubber excelling in sustainable insulation and neoprene dominating in performance-driven environments.

Key Material Properties of Cork Rubber

Cork rubber is a composite material combining natural cork granules with synthetic rubber, offering exceptional flexibility, compressibility, and excellent resistance to moisture, oils, and abrasion. Its low density and thermal insulation properties make it ideal for applications requiring lightweight materials with cushioning effects and sound damping. Unlike neoprene, cork rubber provides superior eco-friendliness and biodegradability while maintaining durability in various industrial sealing and gasketing applications.

Key Material Properties of Neoprene

Neoprene offers excellent resistance to oil, chemicals, and extreme temperatures, making it a versatile material in various industrial applications compared to Cork Rubber. Its superior elasticity and durability ensure long-lasting performance and effective cushioning under mechanical stress. Neoprene's resistance to water and ozone further enhances its suitability for outdoor and marine environments.

Durability and Longevity Comparison

Cork rubber exhibits superior durability due to its natural resistance to wear, moisture, and UV exposure, making it ideal for long-lasting applications. Neoprene offers strong resilience against oil, chemicals, and temperature fluctuations but tends to degrade faster under prolonged UV light and ozone exposure. In terms of longevity, cork rubber generally outperforms neoprene in outdoor and environmentally harsh conditions, providing extended service life.

Environmental Impact: Cork Rubber vs Neoprene

Cork rubber is a sustainable material derived from the bark of cork oak trees, making it biodegradable and renewable with a low carbon footprint, whereas neoprene is a synthetic rubber produced from non-renewable petroleum resources and generates significant greenhouse gas emissions during manufacturing. The biodegradability of cork rubber ensures minimal environmental pollution and landfill waste compared to neoprene, which can persist for decades in landfills due to its synthetic composition. Cork rubber's eco-friendly harvesting process supports biodiversity and carbon sequestration, contrasting with neoprene's reliance on energy-intensive chemical synthesis and potential toxic byproducts.

Typical Applications and Use Cases

Cork rubber is commonly used in automotive gaskets, sealing solutions, and vibration damping due to its flexibility, compressibility, and resistance to oils and fuels. Neoprene excels in industrial applications requiring chemical, weather, and ozone resistance, such as protective gloves, hoses, and weather strips. Both materials suit sealing and cushioning roles, but cork rubber is preferred for quieter environments while neoprene is favored for tougher, outdoor conditions.

Performance in Sealing and Gasketing

Cork rubber offers excellent compressibility and resilience, making it ideal for sealing irregular surfaces and preventing leaks in low to moderate pressure applications. Neoprene provides superior chemical resistance, durability, and temperature stability, excelling in harsher environments requiring long-lasting gasket performance. Choosing between cork rubber and neoprene depends on specific sealing requirements such as pressure tolerance, exposure to oils or solvents, and temperature conditions.

Cost Considerations and Affordability

Cork rubber offers a cost-effective alternative to neoprene due to its natural abundance and lower production expenses, making it ideal for budget-conscious applications in insulation and gaskets around Cork, Ireland. Neoprene, while generally more expensive, provides superior durability and chemical resistance, which can justify higher upfront costs for industrial uses requiring enhanced performance. Evaluating long-term affordability entails considering initial material costs against the lifespan and maintenance needs specific to Cork's climate and environmental conditions.

Safety and Health Aspects

Cork rubber is a natural, hypoallergenic material that offers excellent resistance to mold, mildew, and bacteria, making it a safer choice for individuals with chemical sensitivities. Neoprene, while durable and water-resistant, contains synthetic chemicals such as chloroprene that may release volatile organic compounds (VOCs) and cause skin irritation in sensitive users. Choosing cork rubber reduces health risks associated with long-term exposure to synthetic materials, promoting better indoor air quality and minimizing allergic reactions.

Choosing Between Cork Rubber and Neoprene

Choosing between cork rubber and neoprene depends largely on the intended application and environmental conditions. Cork rubber offers excellent natural cushioning, moisture resistance, and eco-friendliness, making it ideal for gaskets, insulation, and sustainable products in Cork-based manufacturing. Neoprene provides superior chemical resistance, durability, and flexibility, favored in industrial seals, wetsuits, and automotive parts where long-lasting performance in harsh conditions is critical.

Cork Rubber vs Neoprene Infographic

materialdif.com

materialdif.com